The global 3D printing materials and equipment market size is estimated to reach around USD 7.35 billion by 2034 from USD 2.70 billion in 2024, with a CAGR of 10.53%.

3D Printing Materials and Equipment Market Key Points

- North America accounted for the major revenue share of 40% in 2024.

- Asia Pacific is expected to grow at a significant CAGR from 2025 to 2034.

- By material type, the metals segment held the major market revenue share in 2024.

- By material type, the plastics segment is expected to expand at the highest CAGR over the upcoming period.

- By product, the fused deposition modelling (FDM) segment held the biggest market share in 2024.

- By product, the selective laser sintering (SLS) segment is expected to grow at the highest CAGR in the coming years.

- By end-user, the industrial segment contributed the biggest revenue share in 2024.

- By end-user, the automotive segment is expected to register the fastest CAGR during the forecast period.

Overview of the 3D Printing Materials and Equipment Market

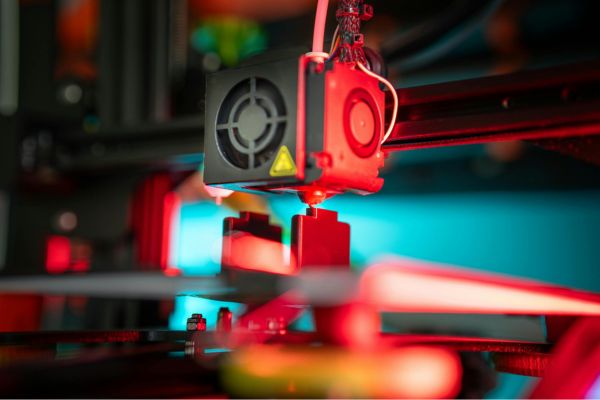

The 3D printing materials and equipment market has rapidly evolved as additive manufacturing gains widespread adoption across industries such as automotive, aerospace, healthcare, and consumer goods. 3D printing equipment includes a variety of technologies such as fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA), each serving different purposes based on precision, material compatibility, and cost-efficiency.

Materials used range from metals and polymers to ceramics and composites, catering to both prototyping and end-use production. The rising demand for customized products and functional parts has significantly boosted the adoption of advanced 3D printers and high-performance materials.

In recent years, technological advancements have led to more affordable, faster, and higher-resolution 3D printers, encouraging small and medium enterprises to enter the market. Sustainability is also emerging as a key trend, with increasing focus on biodegradable or recyclable materials.

Furthermore, the integration of artificial intelligence and automation in 3D printing systems is improving efficiency, accuracy, and material usage. As the ecosystem matures, both materials and equipment segments are expected to experience robust growth, supported by continuous innovation and expanding industrial applications.

How Is AI Transforming the 3D Printing Materials and Equipment Market?

Artificial intelligence is playing a transformative role in the 3D printing materials and equipment market by optimizing the design, production, and material selection processes. AI-powered software can analyse complex design requirements and generate optimized 3D models that reduce material waste and enhance performance.

In equipment operations, AI algorithms monitor printing parameters in real-time, adjusting temperature, speed, and layer precision to ensure consistent quality and minimize defects. This leads to greater efficiency, improved print accuracy, and reduced production time.

AI also enhances material innovation by analysing large datasets to identify new material combinations and predict their properties before physical testing. Machine learning models assist in tailoring material formulations for specific applications, such as lightweight automotive components or biocompatible medical implants.

Additionally, AI-driven predictive maintenance helps minimize downtime by identifying equipment issues before they lead to failures. Overall, AI integration is accelerating innovation and productivity across the entire 3D printing value chain.

Regional Outlook of the 3D Printing Materials and Equipment Market

North America

North America leads the global 3D printing materials and equipment market, accounting for around 40% of revenue in 2024. This dominance is driven by early adoption of additive manufacturing technologies, a robust industrial base, and strong government support.

The United States, in particular, benefits from a concentration of major industry players, high investment in research and development, and widespread use across sectors such as aerospace, defense, healthcare, and education. The region’s focus on innovation and sustainability continues to reinforce its leadership position.

Europe

Europe holds the second-largest market share, with significant contributions from countries like Germany, France, Italy, and Sweden. The region’s strong industrial foundation, particularly in automotive and aerospace, drives demand for 3D printing.

Small and medium-sized enterprises in Europe increasingly adopt 3D printing for rapid prototyping and cost-effective manufacturing. Ongoing policy support, collaboration between industry and research institutions, and a focus on technological advancements further bolster the European market.

Asia-Pacific

Asia-Pacific is the fastest-growing region in the 3D printing materials and equipment market. China is a major hub, propelled by government initiatives such as “Made in China 2025,” significant manufacturing capabilities, and rapid technological advancements.

The region’s growth is also supported by increased adoption in automotive, healthcare, and consumer electronics industries. India is emerging as a key player, with government-backed strategies and a growing ecosystem supporting adoption in aerospace, automotive, and healthcare sectors

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 7.35 Billion |

| Market Size in 2025 | USD 2.98 Billion |

| Market Size in 2024 | USD 2.70 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 10.53% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material Type, Product, End-users, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segmental Analysis of the 3D Printing Materials and Equipment Market

Material Type Insights

The market is segmented by material type into metals, plastics, and others. Metals held the largest revenue share in 2024, driven by their superior strength-to-weight ratio, corrosion resistance, and biocompatibility—qualities that make them ideal for high-performance applications in aerospace, medical, and automotive sectors. Stainless steel is popular due to its mechanical properties and versatility.

Meanwhile, plastics are expected to grow at the highest CAGR, thanks to their cost-effectiveness, versatility, and the continuous development of high-performance and sustainable plastic materials. Plastics are particularly favoured for prototyping and small-scale production due to their lower costs compared to metals or ceramics.

Product Insights

The product segment is dominated by fused deposition modelling (FDM), which leads the market due to its ease of use, affordability, and broad material compatibility. FDM is widely used for rapid prototyping across industries like manufacturing, construction, aerospace, and healthcare.

Selective laser sintering (SLS) is projected to grow at the fastest rate, attributed to its speed, versatility, and ability to produce durable parts with excellent mechanical properties. SLS is well-suited for functional prototyping and digital manufacturing, especially in sectors requiring high strength and customization.

End-User Insights

The industrial segment dominated the end-user market in 2024, reflecting the technology’s ability to produce complex, high-precision parts and prototypes quickly and cost-effectively. Industries such as aerospace, automotive, and manufacturing are major adopters, leveraging 3D printing to optimize designs, reduce waste, and accelerate product development.

The automotive sector is expected to register the fastest growth, driven by the demand for customized parts and the advantages of rapid prototyping, on-demand production, and cost savings for low-volume or niche applications.

3D Printing Materials and Equipment Market Companies

- Hoganas AB: Hoganas AB is a global leader in metal powder technology for additive manufacturing. The company offers a broad portfolio of high-purity metal powders, including custom-developed alloys for industries such as automotive, aerospace, and medical.

Hoganas is recognized for its ability to produce tailored powders at various scales, from laboratory to industrial production, and is at the forefront of innovation in powder handling and material efficiency.- SLM Solutions: SLM Solutions specializes in selective laser melting (SLM) equipment, providing advanced metal 3D printers that enable the production of complex, high-strength metal parts. Their technology is widely used in aerospace, automotive, and medical sectors for both prototyping and end-use components.

- 3D Systems Inc: 3D Systems Inc is a pioneer in the 3D printing industry, offering a wide range of printers and materials for both plastics and metals. The company serves sectors such as healthcare, aerospace, and industrial manufacturing, focusing on both rapid prototyping and production solutions.

Optomec: Optomec is known for its proprietary additive manufacturing equipment, particularly in the field of metal and electronics 3D printing. The company’s technologies support applications in aerospace, energy, and electronics, enabling direct-write and laser-engineered net shaping processes.

Concept Laser GmbH: Concept Laser GmbH, now part of GE Additive, is a key player in the metal additive manufacturing market. It provides laser-based 3D printers that are extensively used in high-precision industries like aerospace, medical, and automotive.

- LPW Technology, Ltd: LPW Technology, now part of Carpenter Additive, specializes in the development and supply of metal powders and powder management solutions for additive manufacturing. The company is known for ensuring material quality and traceability for demanding industrial applications.

- Stratasys Ltd: Stratasys Ltd is a market leader in high-performance polymer materials and industrial 3D printers. The company is known for its innovation in medical, automotive, and aerospace sectors, offering both equipment and a wide range of proprietary materials.

- Royal DSM N.V: Royal DSM N.V is a major supplier of advanced polymer materials for 3D printing, focusing on sustainable and high-performance solutions for industries such as medical, automotive, and consumer goods.

- Arcam AB: Arcam AB, part of GE Additive, specializes in electron beam melting (EBM) technology for metal additive manufacturing. The company serves aerospace and orthopedic implant markets with high-quality titanium and cobalt-chrome parts.

- EnvisionTEC GmbH: EnvisionTEC GmbH is known for its professional-grade 3D printers and materials, especially in dental, medical, and jewelry applications. The company offers precise and reliable equipment for small-batch and custom production.

- Arkema S.A: Arkema S.A is a leading provider of specialty resins and composite materials for 3D printing, supporting a variety of industrial applications with high-performance polymers and innovative material solutions.

- Voxeljet AG: Voxeljet AG focuses on large-format 3D printers and industrial-grade materials, catering to automotive, aerospace, and foundry sectors with solutions for rapid prototyping and production of complex parts.

- Solidscape Inc: Solidscape Inc specializes in high-precision wax pattern 3D printers, primarily serving the jewelry and investment casting markets with equipment and materials that enable detailed and accurate casting patterns.

- EOS GmbH (Electro Optical Systems): EOS GmbH is a global leader in both polymer and metal 3D printing equipment and materials, widely used in aerospace, automotive, and medical industries for prototyping and production of functional parts.

- ExOne: ExOne is a pioneer in binder jetting technology, providing industrial 3D printers and a range of metal, ceramic, and sand materials for applications in automotive, aerospace, and foundry industries.