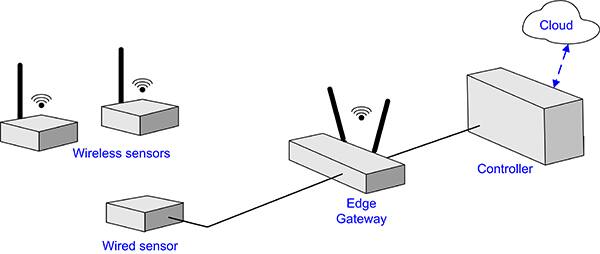

In a world increasingly dependent on wireless connectivity, designers of systems for applications such as marine GPS, industrial IoT, smart agriculture, and unmanned aerial vehicles need RF components that can reliably operate under extreme environmental conditions. Their challenges include vibration, dust, high humidity, exposure to water or other fluids, and salt spray. While the system must be designed to withstand these harsh conditions, a key concern is the RF interconnect, where a coaxial connection transmits RF signals between devices or between a device and an antenna. Designers need to be sure the connectors and cables they use are well-suited to the task while also meeting increasing performance and connection density requirements.

This article briefly discusses the challenge of designing for extreme environments before introducing RF adapters, connectors, and cable assemblies from Amphenol RF. It shows how these components can help protect against moisture, dust, vibration, and corrosion, sealing enclosures while providing superior RF performance in compact connector bodies suitable for high-density packaging.

Extreme environments

From the factory floor to oil rigs, the Industrial Internet of Things (IIoT) is an example of an application that uses RF devices in an environment that may include high humidity, steam, sprayed or splashed liquids, dust, or corrosive chemicals like salt water (Figure 1).

IIoT uses smart sensors, actuators, robots, and similar devices to enhance manufacturing processes. These devices are networked, providing data collection, exchange, analysis, and control. Sharing data from multiple machines and systems aids in making industrial processes more efficient and reliable.

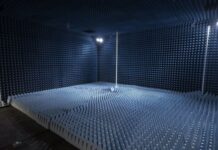

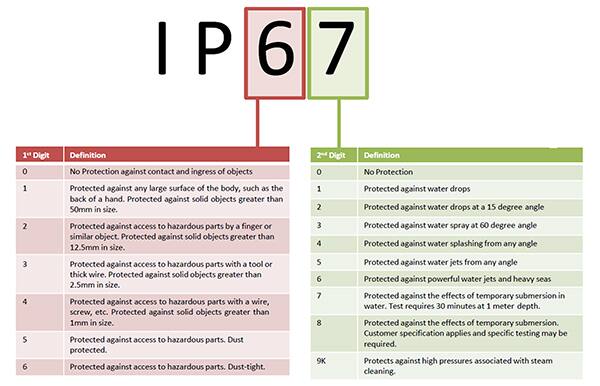

If designing devices like these, you must consider the environment. Extreme environments require that the device be sealed, and any ports must be corrosion-resistant and leak-proof. Metallic enclosures require external antennas. Connectors are also needed for sensors external to the device and signal interconnections with other devices. Coaxial connectors for antennas or signal cables must be sealed using their housings and gaskets to meet these exposure tolerance requirements. The industry standard IEC 60529 uses ingress protection (IP) ratings to define the degree of protection any given connector provides. IP ratings consist of the letters IP followed by a two-digit number. The first digit indicates the degree of protection against dust and solid particle ingress. The second digit indicates the degree of protection against water ingress. The definitions for the IP rating vary from no protection to complete protection, with the higher numbers indicating greater protection (Figure 2).

Connectors suitable for extreme environmental exposure should have an IP rating of 67 or 68. The IP67 rating indicates a dust-tight seal and protection against water, including full submersion for 30 minutes at up to 1 meter of depth.

IP67-rated coaxial connectors

Amphenol RF offers a wide variety of dust-tight and waterproof IP-rated SMA, BNC, and TNC-type coaxial connectors. The model 901-10746-EE is an example of an SMA jack for RG-58 cable intended for bulkhead mounting, and it is rated IP67 (Figure 3).

The electrical characteristics of this SMA female connector include a nominal impedance of 50 ohms (Ω) for RG-58 coaxial cable. It operates over a frequency range from DC to 6 gigahertz (GHz) with a maximum voltage standing wave ratio (VSWR) of 1.30:1, which is equivalent to a return loss of -18 decibels (dB), and it has a dielectric breakdown rating of 1000 volts RMS (Vrms). Its operating temperature range is -65°C to +165°C. The assembly process starts with soldering the center conductor to the connector pin. The pin and cable are inserted into the connector with the braid over the knurl. The ferrule is then crimped over the braid. The O-ring gasket seals the connector body to the mounting panel.

The body of the connector is brass, the ferrule is copper, and both have a corrosion-resistant tin-nickel alloy plating. The plating meets MIL-STD-202 method 101 salt spray standard for a 5% salt solution repeated over 720 hours. After salt spray exposure, the plating integrity is verified, and the RF performance of the connector, including contact resistance and return loss, is retested.

The center conductor contact is beryllium-copper with gold plating and is inserted into a Teflon dielectric. It meets IP67 requirements in an unmated state when assembled with the cable and ferrule.

The connector is mounted to a panel with stainless-steel hardware and sealed with a silicone rubber gasket to guarantee its physical integrity and IP67 conformance.

A mating SMA plug is the Amphenol RF 901-9876-RFX-EE. This in-line, cable-mounted SMA plug has the same material composition and plating as the bulkhead jack and operates over the same temperature range. It mates with the jack using a threaded ferrule over the jack’s threaded body. Like the 901-10746-EE, the plug is rated IP67 and is designed to work with RG-58 cables. It has an operating frequency range from DC to 12.4 GHz.

These RF connectors for extreme environments are also available as BNC and TNC types. A TNC connector is a threaded version of a BNC connector. Threaded connectors, when tightened to their specified torque, are vibration resistant. The 031-6501-EE (Figure 4, left) is a TNC right-angle plug that uses the same materials and meets the same IP67 and corrosion resistance standards as the SMA connectors. It is rated to operate over a temperature range of -40°C to 85°C. Electrically, it has a 50 Ω characteristic impedance and an operating frequency range of up to 6 GHz. Right-angle connectors eliminate the need for cable bends, minimizing the chance of damage to the coaxial cable, while also saving space in small enclosures used in IIoT and similar systems. The 031-6501-EE can be matched with a mating bulkhead adaptor, such as the AD-TNCJTNCJ-EE (Figure 4, right).

The AD-TNCJTNCJ-EE is rated IP68, is corrosion resistant, and has an operating temperature range of -65°C to +165°C. Its characteristic impedance is 50 Ω, and it operates up to 18 GHz. Its VSWR is 1.2:1 (equivalent to a return loss of -21 dB) for frequencies between 0 and 11 GHz, and 1.3:1 (equivalent to a return loss of -18 dB) for frequencies between 11 and 18 GHz. Bulkhead adaptors permit cables to be disconnected from a mounting panel or door so that it can be easily removed for service.

BNC connectors are like TNC units, differing primarily in the locking mechanism. A BNC is a quick connect/disconnect connector that uses two bayonet lugs on the jack side that engage slots on the plug assembly, locking them together with a quarter-turn twist. They also offer IP67 ingress protection and corrosion resistance to salt spray.

The 031-6924-EE BNC plug (Figure 5, left) has an operating temperature range of -40°C to +85°C. Its 50 Ω characteristic impedance is compatible with RG-58 cable. It has a VSWR of 1.30:1 (equivalent to a return loss of -18 dB) and a frequency range of DC to 6 GHz.

The AD-BNCJBNCJ-EE mating receptacle (Figure 5, right) is a jack-to-jack bulkhead adaptor that is also a 50 Ω connector with a maximum frequency of 12 GHz. Its VSWR is 1.30:1 (equivalent to a return loss of -18 dB) from DC to 4 GHz, and less than 1.45:1 (equivalent to a return loss of -15 dB) from 4 to 12 GHz. Its operating temperature range is -40°C to +85°C.

Conclusion

When designing wireless devices, designers must consider the physical and electrical application requirements to ensure product functionality and longevity. Coaxial RF connectors used in wireless systems have the primary task of maintaining signal integrity regardless of the surrounding environment. To that end, selecting high-reliability connectors and adaptors that can withstand vibration, liquid intrusion, dust, and corrosion is essential. The Amphenol RF extreme exposure connectors are ideal for designs intended to operate in severe environments.