Introduction

Electronics has never been the same, especially after the advent of technologies like Process Automation and AI-enabled systems. The Global revenue in the consumer electronics market has been forecasted to increase between 2024 and 2029 by in total 146.3 billion US dollars, however after the fifth consecutive increasing year the indicators suggest the figure to reach 1.1 trillion US dollars which is a new peak in 2029. Times have changed, and the demand for performance, compactness and energy efficiency have surfaced levels beyond what was expected in the 2010s. Process Automation was basically limited to just traditional rule-based systems, with lesser authority as it was confined to pre-built scripts. However, the latest trends of Agentic AI, their powerful capacity to autonomously perform tasks, and learn over time, is surely going to impact process automation in the electronics industry to a bigger extent. Enough of the basics, let’s just learn more about the companionship of process automation and the electronics industry.

How does Process Automation Impact Electronics Manufacturing?

Process automation can be defined as the integration of technologies, like, computer vision, AI powered robotics, and machine learning to enhance the functionality, efficiency and accuracy of the processes. It leads to better outcomes, with lesser involvement of human efforts in activities. Enterprises can integrate computer vision, robotic arms and predictive analytics to enhance the capacity of modern production lines, to perform high end tasks with more speed and efficiency.

In electronics automation, process automation might involve robotic assembly lines, software applications for testing and automated inspection systems. The goal of automation is simple and clear to make the process as optimized as possible. Process automation ensures that the manufacturing processes are consistent. Process Automation in electronics manufacturing can minimize operational expenses by up to 90%.

While talking of efficiency, Intelligent Automation is highly critical as it minimizes cycle times and human error, resulting in a better consistency in production. When Surface Mount Technology is combined with features like real time defect trackers, the speed of PCB speeds up by 50%. Cost reduction is another major advantage of process automation as its AI and machine learning systems reduce wastage, employee costs and scope of reworks, thus enhancing process reliability. The integration of predictive and maintenance, supported by IoT and AI, enables avoiding downtimes by forecasting equipment concerns, before it escalates.

Electronic Process Automation will create a sustainable and scalable approach towards manufacturing, creating a shift to stay highly competitive in this growing electronics industry.

PCB Manufacturing Automation

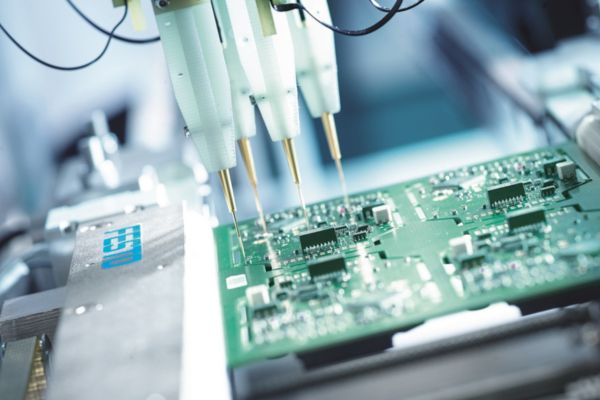

Printed Circuit Board (PCB) manufacturing is a sophisticated process with high demands. Automation promises more precision, efficiency and streamline production. Smart Technologies like SMT, pick and place robots and wave soldering have pushed the limits of PCB manufacturing. Automated PCB manufacturing helps engineers to set new boundaries of possibilities, enabling the creation of complicated designs with ease and accuracy. The biggest advantage is the ability to operate on iterative changes in design rapidly without disrupting the manufacturing process, which enhances the overall flexibility in pcba projects.

The automated systems help in integrating complicated software tools that help in layout optimization, offering better positioning of each component. It also aids hi performance electronic devices by improving signal integrity and minimizing interference. By implementing advanced algorithms and real time feedback systems, these automated designs are able to meet the street quality standards. Automation empowered the management of multi-layer PCBs that are a prerequisite in modern electronics delivering new benchmarks in electronic device innovation. PCB manufacturing has been highly strengthened by AI, IoT and CV, offering rapid and accurate operations.

Process Automation in Quality Control

Electronics Manufacturing is highly sophisticated, with several quality standards to be met. AI survives on data, and within this industry even if the dataset is of 100 units, AI algorithms can learn from it easily. Quality detection is bound by rules and regulations, making it easier for AI to get trained on the set script and function with higher awareness. Humans are not great in terms of quality inspection paving a way for AI to get trained and fine-tune mechanisms.

With Agentic AI into play, it autonomously reduces inspection set up times and enhances the accuracy of defects investigation. For instance, CV systems can perform efficiently even in times of continuous improvement on the production lines as it can learn from the rules for every version of the product. Agentic AI is built for its autonomous brilliance, and with its high adaptability, it can simply adapt to every product or process changes, without human intervention.

These agents can function effectively in the electronics industry, resolving human intervention in repetitive tasks. AI is easier to deploy and adapt to, due to self-learning features. Their predictions don’t only involve known issues, rather they can also identify novel concerns. For example, machine learning algorithms possess superhuman accuracy when it comes to defect identification. In terms of human inspection, the accuracy standard is 80%, whereas for AI it is 99%.

Smart Supply Chain & Inventory Optimization

Logistics accuracy is highly empowered by technologies like RPA and IoT. It transforms demand forecasting and inventory management. The combination of RPA and AI involves accumulation and processing of real time information from different sources, helping them to automate activities like invoicing, inventory updates and order processing. This ensures that the supply chain functions are optimized and efficient. With IoT sensors in action, it can provide continuous information on stock levels, current conditions of weather and shipment status, taking demand forecasting to a new level.

Maintaining stock levels in logistics is vital, which can easily be managed by autonomous procurement tools. They can forecast shortages and surpluses, without any human assistance. McKinsey states that enterprises benefit from AI and Automation in logistics, as they reduce 20% of total expenses.

Accelirate, a renowned AI and Automation company partnered with a Electronics Distributor, and implemented real time inventory management, resulting in enhanced order processing and revenue. It integrated SAP analytics cloud, MuleSoft and Salesforce technologies to centralize data management and optimize logistics. It enabled the electronics distributor to enhance overall business processes and decision making.

Click here, to learn more about Supply Chain automation.

Challenges of Process Automation in Electronics

The primary challenge faced by electronics organizations while implementing process automation is the high initial investment required for implementing technologies like AI, Robotics and MV systems. With most industry people being trained in conventional systems, another major factor is the skill gap. There are necessary requirements of learning additional skills related to AI and automation, for operating the processes smoothly. With automated systems, most processes become interconnected enhancing the risks of Cyber Threats. With effective cybersecurity mechanisms in place, it will be easier for enterprises to operate with additional stress of hacks and breaches.

The Future of Process Automation in Electronics Industry

The impact of process automation within the electronics industry is quite clear. There are more technologies that are still under development, which will make this industry more effective and functional. AI driven self-healing systems which will ensure autonomous prediction and decision making to correct defects within production systems. Moreover, 3D printing will also transform manufacturing mechanisms in the electronic industry by faster prototyping and on demand production. The ongoing movement around sustainability has demanded greener automation Technologies aimed at reducing waste and consumption. With this trend in action, supposedly there might be an introduction of sustainable automation processes.