The construction industry has long been plagued by inefficiencies—delays, budget overruns, and unforeseen setbacks that disrupt even the most meticulously planned projects. From bridges and highways to skyscrapers, the sector’s struggles with time and cost management have become almost synonymous with large-scale infrastructure development. But what if these challenges could be anticipated and mitigated before they even arise? Enter digital twins, a transformative technology that is reshaping the future of construction.

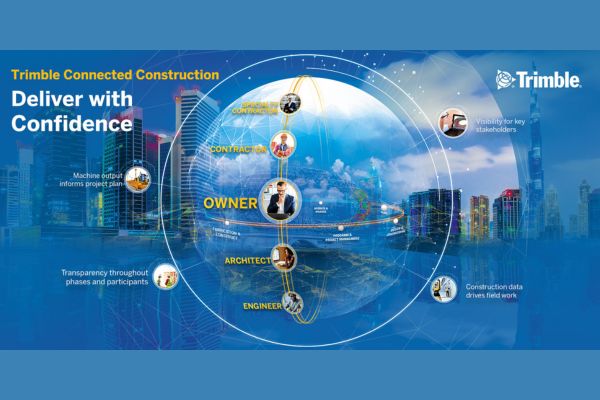

Digital twins, real-time virtual replicas of physical structures, are enabling engineers and project managers to simulate, predict, and optimize every aspect of a project before a single brick is laid. At the forefront of this revolution is Trimble, a global leader in advanced construction technology, whose digital twin solutions are empowering the industry to build smarter, safer, and more sustainably.

Trimble’s digital twin solutions transform 3D models into highly detailed digital replicas, integrating geospatial intelligence, machine learning, and real-time collaboration. These tools allow for precise mapping and representation of infrastructure networks, including utilities, roads, and railways. By enabling real-time data collection and design verification, Trimble ensures that digital models accurately reflect their physical counterparts, reducing errors and inefficiencies during construction.

The implications of this technology extend far beyond project management. Digital twins are proving to be a game-changer for sustainability, a critical concern in an industry responsible for nearly 40% of global carbon emissions. Traditional construction methods often result in significant material waste and energy inefficiencies. However, by combining digital twins with advanced Building Information Modeling (BIM) solutions, developers can optimize material usage, enhance energy efficiency, and minimize waste.

A Sustainable Future for India’s Construction Sector

India, with its rapid urbanization and burgeoning infrastructure needs, stands to benefit immensely from this technological shift. The country’s construction sector is under pressure to meet the demands of a growing population while adhering to sustainable development goals. According to the Indian Green Building Council (IGBC), green buildings in India have demonstrated a 25-30% reduction in energy consumption compared to national baselines. Digital twins can further amplify these gains by enabling precise resource allocation, reducing material wastage by up to 30%, and allowing developers to simulate construction strategies that balance cost, efficiency, and environmental impact.

Trimble’s digital twin solutions are already helping Indian Trimble’s Vision construction companies improve the sustainability and efficiency of their projects. By leveraging real-time modeling and monitoring tools, developers can minimize material usage and ensure that every aspect of a project is meticulously planned before construction begins.

Enhancing Worker Safety

Worker safety is another critical area where digital twins are making a significant impact. India’s construction sector employs over 50 million workers, many of whom face hazardous working conditions. A report by the British Safety Council reveals that approximately 48,000 workers in India lose their lives in occupational accidents annually, with the construction industry accounting for 24.2% of these fatalities—equivalent to 38 deaths per day.

Digital twins are helping to address this grim reality by enabling site managers to proactively identify safety hazards. By simulating site conditions and integrating real-time sensor data, project teams canTrimble’s Vision detect structural vulnerabilities, monitor air quality, and ensure compliance with safety standards. This proactive approach not only reduces workplace accidents but also enhances overall labour productivity.

Driving Cost Efficiency

Cost overruns remain a persistent challenge in India’s construction industry, particularly in large-scale projects. Digital twins offer a dynamic, data-driven solution to this problem. By providing real-time insights into labour deployment, material availability, and supply chain logistics, developers can prevent costly inefficiencies. Digital Twins and Smart Construction Furthermore, predictive maintenance enabled by digital twins can extend the lifespan of infrastructure assets, reducing long-term operational costs.

Trimble’s integration of artificial intelligence, cloud computing, and geospatial intelligence into its digital twin technology is empowering Indian construction companies to tackle these challenges head-on. With real-time project tracking and data-driven decision-making, developers can enhance productivity, safety, and sustainability across their projects.

Redefining India’s Construction Future

Despite its transformative potential, the adoption of digital twin technology in India is not without hurdles. Technical expertise and initial implementation costs remain significant barriers. However, the long-term benefits—improved efficiency, reduced waste, enhanced safety, and cost savings—far outweigh these challenges. As more Indian cities and infrastructure projects embrace digital twin solutions, the construction industry is poised for a paradigm shift toward smarter, more sustainable practices.

The integration of digital twins into construction is not merely about adopting new technologies; it is about redefining how India builds its future. By enabling smarter planning, safer worksites, and more sustainable practices, digital twins are paving the way for a construction industry that is as efficient as it is innovative.

As Trimble continues to lead this transformation, the vision of a smarter, safer, and more sustainable construction sector is becoming a reality. For India, a nation on the cusp of unprecedented urban growth, digital twins represent not just a technological advancement, but a blueprint for building a better tomorrow.

By Mr. Harsh Pareek, Regional Sales Director, India and SAARC, Trimble Solutions.