The global machine vision market size surpassed USD 20.4 billion in 2024 and is expected to attain around USD 69.49 billion by 2034 with a CAGR of 13.04% from 2025 to 2034.

Machine Vision Market Key Insights

- Asia Pacific led the global market with the largest share of 44% in 2024.

- North America is projected to experience the fastest growth, with the highest CAGR during the forecast period.

- By offering, the hardware segment dominated the market in 2024.

- By offering, the software segment is expected to see the fastest growth over the forecast period.

- By product, the PC-based segment led the market in 2024.

- By product, the smart camera-based segment is anticipated to grow at the fastest CAGR during the forecast period.

- By application, the quality assurance and inspection segment dominated the market in 2024.

- By application, the identification segment is projected to grow at the fastest rate over the forecast period.

- By end use, the automotive segment accounted for the largest market share in 2024.

- By end use, the pharmaceuticals and chemicals segment is expected to expand at the fastest CAGR during the study period.

How Is AI Transforming the Machine Vision Market?

AI is revolutionizing the machine vision market by enhancing image processing, object recognition, and real-time decision-making. Advanced AI algorithms, particularly deep learning, enable systems to detect defects, identify objects, and analyse visual data with high precision and speed. This improves quality control, inspection, and automation in industries such as automotive, electronics, and pharmaceuticals, where accuracy and efficiency are critical.

Additionally, AI-driven machine vision systems enable predictive maintenance and improve production line automation. By analysing visual data, AI can predict equipment failures, reducing downtime and maintenance costs. The integration of AI with other technologies like robotics and IoT further optimizes production processes, making operations faster, more efficient, and cost-effective while ensuring consistent quality.

What Is Machine Vision and How Does It Work?

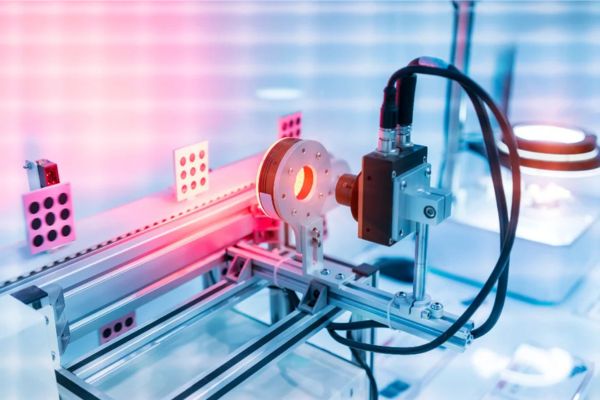

Machine Vision refers to a technology that enables machines to interpret and process visual data from the world in a similar way to human vision, but with much higher speed, accuracy, and consistency. It uses cameras, sensors, and image processing algorithms to capture and analyse images or video feeds for specific tasks such as inspection, measurement, and navigation.

Key Components of Machine Vision:

Cameras and Sensors: The most fundamental part of machine vision systems, these devices capture visual data, including images and videos, from the environment.

Lighting: Proper lighting is crucial to ensure clear and accurate image capture. Different lighting techniques, such as diffuse, backlighting, and coaxial, are used to highlight specific features.

Image Processing Software: The captured data is processed by specialized software that uses algorithms for tasks such as object detection, pattern recognition, defect identification, and dimensional measurements.

Controllers/Processors: These are responsible for handling data from cameras, processing it through algorithms, and sending outputs to other systems, such as robots or automated machines.

Outputs and Decision-Making: Based on the processed data, machine vision systems can trigger automated responses, such as sorting, rejecting defective parts, or guiding robotic arms for assembly.

Applications of Machine Vision:

Quality Control and Inspection: Machine vision is widely used in manufacturing to inspect products for defects, ensuring they meet quality standards. It can detect flaws at a micro-level, which human inspectors might miss.

Automation in Manufacturing: In production lines, machine vision systems enable robots to perform tasks like picking, placing, and assembling objects with precision.

Object Identification and Sorting: Machine vision is used in logistics for sorting and identifying objects in warehouses or supply chains based on shape, size, color, or other visual features.

Guidance for Autonomous Vehicles: Machine vision plays a critical role in autonomous vehicles, helping them navigate, detect obstacles, and interpret road signs or traffic conditions.

Agriculture: In precision farming, machine vision is used for monitoring crops, detecting diseases, and guiding autonomous farming equipment.

Benefits of Machine Vision:

Increased Speed and Efficiency: Machine vision systems can operate faster than humans, allowing for high-speed inspections and processes in industries such as automotive and electronics.

High Precision and Accuracy: The technology can detect minute defects or measure dimensions with great accuracy, enhancing product quality and reducing waste.

Reduced Labor Costs: Automation of visual inspection and other tasks can significantly cut down the need for manual labour, reducing costs and increasing efficiency.

24/7 Operation: Unlike humans, machine vision systems can operate continuously, ensuring consistent performance without fatigue or downtime.

Regional Outlook of Machine Vision Market

The Asia Pacific region dominated the global machine vision market in 2024, holding the largest market share of approximately USD 8.98 billion. This dominance is driven by rapid industrialization and production expansion in emerging economies such as China, Japan, India, and Taiwan. The region benefits from strong growth opportunities in sectors like pharmaceuticals, packaging, automotive, and other industrial applications.

Additionally, initiatives promoting smart manufacturing and Industry 4.0 are accelerating adoption. Japan leads within the region, primarily due to its aging population and labour shortages, which increase the need for automation and machine vision technologies to maintain high product standards while reducing costs.

- In October 2023, Emerson announced the acquisition of NI. NI increases Emerson’s end-market exposure in discrete markets, which will be Emerson’s second-largest industry segment. With approximately 20% of its sales in software, NI also increases Emerson’s exposure to high-growth industrial software markets.

North America is expected to register the fastest compound annual growth rate (CAGR) during the forecast period from 2025 to 2034. The region’s growth is fueled by the presence of major manufacturers, advancements in semiconductor technology, and innovations in 3D machine vision systems. Key players in this region are actively developing 3D technology-based vision systems, which are expected to further propel market expansion.

Europe is also a significant market for machine vision, supported by strong industrial bases and increasing adoption of automation technologies. The region benefits from investments in manufacturing modernization and quality inspection systems, particularly in automotive, electronics, and pharmaceutical sectors.

Emerging markets in Latin America and Middle East & Africa are witnessing growing interest in machine vision technologies, driven by expanding industrialization and increasing demand for automation and quality control. These regions are expected to experience moderate growth as infrastructure develops and awareness of machine vision benefits increases.

Segmental Analysis of Machine Vision Market

Offering Insights

Hardware dominated the market in 2024, driven by ongoing launches of advanced components such as image sensors, cameras, lenses, lighting systems, frame grabbers, processing units, and communication interfaces. These hardware elements form the foundation of machine vision systems, enabling effective visual data acquisition.

Software is expected to grow at the fastest CAGR during the forecast period, fueled by increasing demand for precise quality inspection, process automation, and defect detection. The integration of artificial intelligence (AI) and machine learning (ML) technologies into vision software enhances image processing capabilities and simplifies analysis.

Product Insights

The PC-based segment led the market in 2024 due to its high processing power, speed, and adaptability in handling complex machine vision tasks. PC-based systems support sophisticated algorithms and large data analysis, offering customization and scalability for diverse applications.

The smart camera-based segment is projected to grow at the fastest rate, propelled by automation efficiency, built-in processing capabilities, and improved design. Smart cameras optimize inspection processes and accuracy, with AI-driven vision inspection systems further accelerating adoption.

Application Insights

The quality assurance and inspection segment dominated in 2024, as machine vision systems are widely used for strict quality control to detect defects, contamination, and production flaws. This leads to improved product quality, reduced waste, and enhanced customer satisfaction.

The identification segment is expected to register the fastest growth, driven by increasing use of machine vision for pattern recognition, barcode scanning, and object identification. Automation in identification processes is transforming workflows and supply chains across industries.

End-Use Insights

The automotive segment held the largest market share in 2024, supported by the growing need for machine vision in driver assistance systems, vehicle perception, safety, lane tracking, and autonomous vehicle development.

The pharmaceuticals and chemicals segment is anticipated to grow at the fastest rate due to stringent quality control requirements and regulatory compliance. Machine vision adoption in this sector supports label verification, defect detection, and packaging integrity, enhancing precision and efficiency.

Latest Announcement

- In January 2025, Cognex Corporation, the leader in industrial machine vision, announced the launch of the DataMan® 290 and 390 barcode readers. Thanks to innovative AI technology, these readers deliver reliable decoding performance across a broad range of manufacturing applications.

- In December 2024, OMRON Electronic Components, a global leader in electronic components and products, announced the latest edition of its G5Q global standard compact power relay, G5Q-HR. Originally launched in 2001, the G5Q series has become a trusted standard in compact power relays, with more than 500 million units sold globally.

Machine Vision Market Companies

- Cognex Corporation

- Keyence Corporation

- LMI Technologies, Inc. (A subsidiary of TKH Group NV)

- Stemmer Imaging

- National Instruments Corporation

- OMRON Corporation

- Sick AG

- Tordivel AS

Source: https://www.precedenceresearch.com/machine-vision-market