The global 3D machine vision market size is expected to attain around USD 27.5 billion by 2034 increasing from USD 7.2 billion in 2024, with a CAGR of 14.34%.

3D Machine Vision Market Key Insights

- Asia Pacific held the largest share of the global market at 42% in 2024.

- North America is anticipated to record the fastest CAGR throughout the forecast period.

- By offering, the hardware segment dominated the market with a 71% share in 2024.

- By offering, the software segment is expected to expand at the highest CAGR during the forecast period.

- By product, PC-based systems accounted for the largest market share of 55% in 2024.

- By product, smart-camera-based systems are projected to grow at the fastest CAGR over the forecast period.

- By application, quality assurance and inspection led the market with a 52% share in 2024.

- By application, the identification segment is forecasted to experience the highest growth rate during the forecast period.

- By end use, the automotive sector contributed the largest share at 20% in 2024.

- By end use, the food and beverage industry are poised to grow at the fastest CAGR in the coming years.

The Transformative Role of AI in Advancing 3D Machine Vision Systems

Artificial Intelligence (AI) plays a crucial role in advancing the 3D machine vision market by enabling more accurate image processing, real-time decision-making, and adaptive learning. AI algorithms enhance the system’s ability to recognize complex patterns, detect defects, and accurately localize objects in three dimensions, even under challenging conditions like partial occlusion or random placement. This leads to improved quality inspection, robotic guidance, and automation processes, making operations faster, smarter, and more efficient across industries.

Additionally, AI allows 3D machine vision systems to continuously learn and adapt to new data, reducing the need for manual reprogramming and increasing system flexibility. It also supports the integration of multiple sensor inputs to create detailed, context-rich 3D models, essential for applications such as autonomous navigation, industrial automation, and augmented reality. Overall, AI significantly enhances the capabilities, scalability, and intelligence of 3D machine vision technologies.

3D Machine Vision Technology: Overview

3D machine vision is a technology that enables machines and automated systems to perceive, analyse, and interpret the three-dimensional structure of objects in their environment. Unlike traditional 2D vision, which only captures flat images, 3D machines vision uses specialized sensors and cameras to obtain depth information, creating detailed 3D maps or point clouds that provide exact spatial coordinates for every pixel. This allows machines to understand the shape, size, orientation, and position of objects with high accuracy.

The core components of 3D machine vision systems include structured light scanners, stereo vision systems, and time-of-flight cameras, all of which work together to deliver precise depth perception and spatial analysis. With this advanced capability, 3D machine vision is particularly well-suited for tasks that require detailed shape information, such as quality control, inspection, robotic guidance, and object recognition in industrial automation.

Regional Outlook of the 3D Machine Vision Market

The Asia Pacific region currently dominates the 3D machine vision market, holding the largest share in 2024 with a market size of USD 3.02 billion. This region is projected to experience robust growth, reaching approximately USD 11.69 billion by 2034 at a compound annual growth rate (CAGR) of 14.49%. The rapid expansion is fuelled by accelerated industrialization, widespread adoption of automation technologies, and significant investments in manufacturing sectors-particularly in countries like China and Japan.

China stands out as the primary contributor, thanks to its strong presence of major industry players, increased research and development activities, and numerous strategic partnerships. Japan also plays a vital role, driven by its focus on advanced manufacturing and automation.

North America is anticipated to be the fastest-growing region in the 3D machine vision market over the forecast period. The region’s growth is propelled by a high rate of technological adoption, especially in the United States, where there is a strong emphasis on operational efficiency, quality control, and the integration of advanced manufacturing systems.

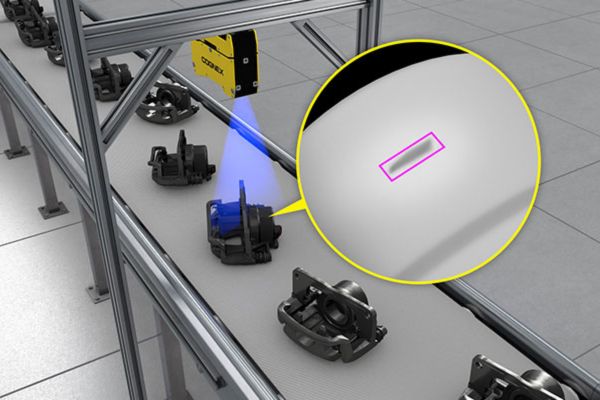

- In April 2024, Cognex Corporation, a global player in industrial machine vision, released the In-Sight L38 3D Vision System. The system combines AI, 2D, and 3D vision technologies to solve a range of inspection and measurement applications.

The U.S. leads the North American market due to its expanding automotive sector and its position at the forefront of industrial automation and innovation.

Europe maintains a significant and steady share of the global market, supported by its robust manufacturing base and the early adoption of Industry 4.0 technologies. The region’s growth is further driven by a strong focus on quality assurance and regulatory compliance within the automotive, electronics, and packaging industries. Ongoing investments in smart factories and digital transformation initiatives also contribute to the continued expansion of the market in Europe.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 27.5 Billion |

| Market Size in 2025 | USD 8.23 Billion |

| Market Size in 2024 | USD 7.2 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 14.34% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Offering, Product, Application, End Use and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segmental Analysis of the 3D Machine Vision Market

Offering Insights

The 3D machine vision market is segmented into hardware and software. In 2024, the hardware segment dominated the market, driven by the rising demand for advanced sensor technologies and imaging systems. Hardware components such as lasers, cameras, and lighting systems are crucial for delivering precise, high-resolution data, especially as industries push for higher levels of automation and quality inspection.

The software segment is projected to grow at the fastest rate in the coming years. This is attributed to the increasing emphasis on IoT and smart manufacturing, which require adaptable software solutions that can seamlessly integrate various hardware systems. Additionally, the adoption of deep learning and artificial intelligence is further accelerating the growth of the software segment.

Product Insights

The market is divided into PC-based and smart camera-based products. PC-based products held the largest share in 2024, benefiting from the ongoing digitalization of work, education, and daily life, as well as the surge in e-commerce and remote work. The demand for high-performance PCs, tablets, and laptops has contributed to this segment’s dominance.

The smart camera-based segment is expected to witness the fastest growth. This is due to the increasing use of smart cameras for high-resolution applications and their ability to interpret and guide objects autonomously, making them highly valuable across various industrial sectors.

Application Insights

In terms of application, the market is segmented into quality assurance & inspection, identification, measurement, and others. Quality assurance and inspection led the market in 2024, underpinned by the growing focus on product quality and regulatory compliance in industries such as automotive, packaging, and labelling. Companies are prioritizing strict quality standards to minimize costs associated with product returns and rework, thus driving the adoption of 3D machine vision systems.

The identification segment is forecasted to grow at the fastest rate, fuelled by the expansion of the e-commerce sector and the need for precise order fulfilment and automated inventory management.

End Use Insights

The end-use segmentation includes automotive, food & beverage, pharmaceuticals & chemicals, electronics & semiconductors, and others. The automotive sector dominated the market in 2024, leveraging 3D machine vision for a range of inspection tasks such as assembly verification, error proofing, and final inspection, all of which are critical for quality and safety.

The food and beverage segment are expected to grow most rapidly, as automation, quality control, and efficiency become increasingly important for sorting, packaging, and inspection processes. The use of 3D machine vision for barcode recognition, label scanning, and defect detection in packaging and bottling operations is especially notable.

Recent Advancements in 3D Machine Vision Market

- In August 2024, SICK AG and Endress+Hauser Group Services AG announced a strategic partnership aimed at advancing process automation to support industrial decarbonization. As part of the collaboration, the companies are forming a joint venture focused on developing innovative process-related solutions, with the goal of delivering comprehensive offerings for the process industry.

- In September 2024, Basler AG, a leading provider of imaging components for computer vision, introduced its new Pylon AI software. This solution enhances machine vision applications by integrating artificial intelligence capabilities, enabling users to implement more advanced image processing and analysis functionalities.

3D Machine Vision Market Companies

Basler AG:

Provides advanced 3D cameras and vision solutions, including time-of-flight and stereo vision cameras, widely used in robotics and automation. Known for integrating AI into machine vision software.

Cognex Corporation:

Global leader offering 3D vision sensors and laser profilers for high-precision inspection, defect detection, and robotic guidance in automotive, electronics, and logistics sectors.

National Instruments Corporation:

Delivers customizable machine vision systems with high-performance cameras and AI-powered software for precise inspection and measurement across various industries.

OMRON Corporation:

Offers a broad range of vision sensors and smart 3D cameras focused on automated inspection, part picking, and robotics, with strong R&D and easy integration tools.

Sick AG:

Known for flexible 3D vision cameras used in industrial automation for sorting, quality checks, and robotic guidance to optimize manufacturing processes.

Allied Vision Technologies GmbH:

Provides 2D and 3D cameras designed for robotics and automation, supporting precise imaging and integration in industrial applications.

Softweb Solutions Inc. (An Avnet Company):

Specializes in AI-driven software and custom machine vision integration services to enhance automation and quality control capabilities.

Visionatics Inc.:

Delivers innovative 3D vision systems tailored for industrial inspection, measurement, and automation to improve efficiency and quality.

Keyence Corporation:

Major supplier of high-performance 3D vision systems and sensors, widely used for quality inspection, measurement, and robotic guidance in manufacturing.

Source: https://www.precedenceresearch.com/3d-machine-vision-market