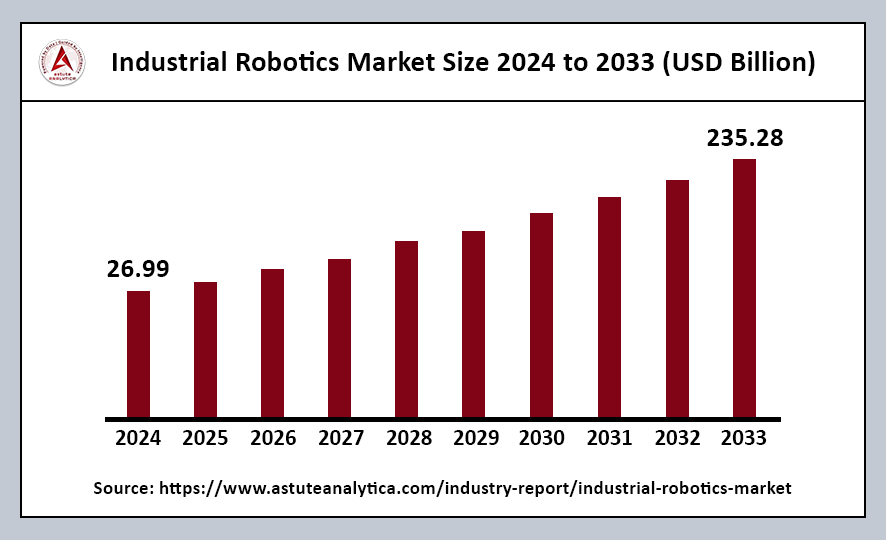

The global industrial robotics market was valued at US$ 26.99 billion in 2024 and is projected to reach US$ 235.28 billion by 2032, reflecting a Compound Annual Growth Rate (CAGR) of 27.2% during the forecast period from 2025 to 2033.

Industrial robots play a crucial role in facilitating high payload lifting during the manufacture of vehicles and the customization of machinery. As smart factories become more prevalent, the market potential for industrial robotics is expected to expand significantly. This growth is driven by several factors, including increasing consumer goods demand, heightened public awareness of industrial accidents, and a strong emphasis on employee safety. These elements collectively contribute to the development of the industrial robotics market, as companies seek to enhance operational efficiency and mitigate risks associated with manual labor.

Industrial Robotics Market Key Takeaways

- By Type, in the industrial robotics market, Cartesian robots hold the largest share, commanding 30.60% of the total revenue share.

- When analyzing the market by function, material handling stands out as the dominant segment, accounting for over 43% of the revenue within the industrial robotics market.

- In terms of industry segmentation, the automotive sector remains the revenue powerhouse of the industrial robotics market, boasting a share of over 25.40%.

Regional Analysis

Dominance of the Asia Pacific Industrial Robotics Market

The Asia Pacific region is a powerhouse in the industrial robotics market, accounting for over 69.0% of global robot installations. This remarkable statistic indicates that nearly seven out of every ten new robots installed worldwide are in this region.

- China’s Central Role in Robotics: China stands at the epicenter of the industrial robotics market in the Asia Pacific. As the world’s largest manufacturer, the country has established a robust industrial base that serves as a fertile ground for the adoption of robotic technologies. Chinese government initiatives actively promote the integration of robotics across various sectors, enhancing productivity and efficiency.

- Strong Manufacturing Base Fueling Growth: The Asia Pacific region benefits from a strong manufacturing foundation that is critical to the growth of the industrial robotics market. With a diverse array of industries, including electronics, automotive, and textiles, the demand for automation solutions is significant. Manufacturers are increasingly recognizing the value of robotics in enhancing operational efficiency, reducing labor costs, and improving product quality.

- Rising Demand for Consumer Electronics and Automotive Products: The increasing demand for consumer electronics and automotive products is another key driver of robotics adoption in the Asia Pacific region. Robotics plays a crucial role in assembly and material handling processes within these industries, streamlining operations and ensuring that production rates keep pace with consumer expectations.

Growth Prospects in the European Industrial Robotics Market

The industrial robotics market in Europe is poised for significant growth throughout the forecast period. This upward trajectory can be attributed to several key factors that align with the region’s strategic focus on sustainability and innovative manufacturing practices.

- Emphasis on Sustainability and Green Manufacturing: Europe’s commitment to sustainability is a driving force behind the growth of the industrial robotics industry. The region has made substantial investments in green manufacturing initiatives, which aim to reduce environmental impact and promote resource efficiency. As companies strive to meet sustainability goals, they are increasingly adopting robotic solutions that enable more efficient production processes.

- Adoption of Collaborative Robots (Cobots): Collaborative robots, or cobots, are becoming increasingly popular in European industries as they enhance operational efficiency while ensuring safety and flexibility. The adoption of cobots is particularly beneficial in sectors such as manufacturing and logistics, where efficiency and safety are paramount.

- Response to Stringent Environmental Regulations: The implementation of stringent environmental regulations in Europe is another significant factor driving the adoption of industrial robotics. These regulations compel industries to seek energy-efficient production methods and implement waste reduction strategies. As industries adapt to meet these requirements, the demand for robotic solutions that facilitate compliance and enhance sustainability will continue to grow.

North America’s Dominance in the Industrial Robotics Market

The North American industrial robotics market is poised to capture a significant revenue share in 2024. This region is experiencing a robust adoption of industrial robots, fueled by the increasing demand for advanced manufacturing solutions across various sectors.

- Improved Productivity: One of the primary motivators is the need for improved productivity. Companies across industries are leveraging robotics to streamline operations, reduce cycle times, and increase output. Additionally, the precision offered by robotic systems is essential in sectors such as aerospace, where the highest quality standards are mandatory.

- Ongoing Labor Shortage: Another significant factor is the ongoing labor shortage in high-skill roles. As the demand for skilled labor continues to exceed supply, businesses are turning to automation as a viable solution. By employing industrial robots, companies can mitigate the impact of labor shortages while maintaining high standards of quality and efficiency in their operations.

- Government Support for Automation: Government initiatives are playing a crucial role in accelerating the deployment of industrial robots throughout North America. Various programs and policies aimed at promoting automation and the adoption of Industry 4.0 technologies are being implemented to support businesses in their transition to more advanced manufacturing practices.

Top Trends Escalating the Industrial Robotics Market

Collaborative Robots Enhancing Workspaces: Collaborative robots, or cobots, equipped with advanced vision systems, are revolutionizing the concept of shared workspaces between humans and robots. By integrating these sophisticated visual capabilities, cobots can effectively navigate their environment and work alongside human operators. The flexibility provided by these shared workspaces is driving the adoption of industrial robots.

Digital Twins and Edge AI for Path Optimization: The implementation of digital twins combined with edge AI technology is transforming how autonomous robots optimize their paths during operations. When paired with edge AI, these digital twins enable robots to make autonomous decisions regarding their movement and operations, enhancing efficiency and reducing downtime. This technology is driving industrial robots by ensuring they can adapt to dynamic environments and optimize their performance without human intervention.

Modular Grippers and Plug-and-Play End-Effectors: The advent of modular grippers and plug-and-play end-effectors is facilitating rapid deployment and agility for multi-tasking applications worldwide. These components allow robots to switch between different tasks and adapt to various production requirements with ease. As industries increasingly demand versatility in their robotic systems, the ability to quickly reconfigure robots for different functions is becoming a significant driver in the industrial robotics market.

Addressing Skilled Labor Shortages: Chronic skilled labor shortages are prompting manufacturers around the globe to turn toward automation-intensive solutions. As the demand for skilled labor continues to outpace supply, automation becomes a viable strategy for maintaining production levels and ensuring operational continuity. Industrial robots are increasingly seen as essential tools for addressing these labor shortages, allowing businesses to maintain efficiency and quality in their operations even in the face of workforce challenges.

Demand from EV and Semiconductor Industries: The rapid expansion of the electric vehicle (EV) and semiconductor industries is creating a pressing need for precise, high-volume production capacity that is robot-enabled. Industrial robots are indispensable in achieving these production goals, driving the need for more sophisticated automation technologies to support the manufacturing processes within these high-growth industries.

Cost Reductions and RaaS Models: Declining robot unit costs, along with the emergence of Robotics as a Service (RaaS) models, are significantly improving return-on-investment timelines for manufacturers. As the initial investment in robotic systems decreases, more companies are willing to adopt automation solutions.

Industrial Robotics Market Segmentation

By Type

Cartesian robots hold the largest share of the industrial robotics market at 30.60% due to their linear architecture, which aligns seamlessly with the rectangular work envelopes prevalent in modern production cells. Their design offers a uniquely favorable combination of precision, footprint efficiency, and an excellent cost-to-performance ratio, making them a preferred choice in various manufacturing applications.

By Function

Material handling, holding over 43% of the market share, dominates revenue within the industrial robotics market. This dominance stems from the fact that virtually every production environment—ranging from steel mills to micro-fulfillment centers—requires the continuous movement of parts between various process steps. Material handling addresses a critical manufacturing pain point by facilitating the movement of components between increasingly automated process islands, thereby meeting the functional demands prevalent in the market.

By Industry

The automotive industry, holding over 25.40% of the market share, serves as the revenue powerhouse of the industrial robotics market. This sector demands an exceptional combination of welding, sealing, painting, and final inspection processes, all executed at high speed and with zero defects. The automotive sector consistently generates the highest revenue in the market, largely due to the ongoing trends of electrification and modular platforms, which are transforming production economics at an unprecedented pace.

Recent Developments in the Industrial Robotics Market

- Amazon Introduces Vulcan: In May 2025, Amazon unveiled Vulcan, a cutting-edge robotic system harnessing physical AI. This innovative system integrates force feedback sensors along with touch and sight capabilities to manage inventory effectively in collaboration with human workers. The introduction of Vulcan marks a significant advancement in automation, aimed at enhancing operational efficiency and improving the overall workflow within Amazon’s fulfillment centers.

- Standard Bots Expands Production: In May 2025, Standard Bots announced the launch of a new robot alongside the expansion of its production facility in Glen Cove, N.Y. The American robotics company revealed that the new 16,000-square-foot (approximately 1486.4 square meters) factory effectively doubles the size of its previous Long Island location. This expansion is a strategic move to scale up production capabilities and meet the growing demand for robotic solutions in various industries.

- Inbolt and Fanuc Launch Breakthrough Robots: In a significant development in May 2025, Inbolt and Fanuc collaborated to launch breakthrough robots capable of thinking and acting on the fly at moving assembly line speeds. This partnership highlights the growing trend of integrating advanced robotics with real-time decision-making capabilities, which is essential for enhancing productivity and efficiency in manufacturing processes.

- Aquajet’s New Robot Launch: In March 2025, Aquajet, a hydrodemolition company, announced plans to launch two new robots in April: the Aqua Cutter 450A and Aqua Cutter 450V. The new electric 450 series features a more compact and maneuverable design compared to the previous Aqua Cutter 750V model. These new robots are equipped with the Evolution 3.0 control system and the patented Infinity oscillation system, ensuring improved performance and versatility in various demolition applications.

Top Companies in the Industrial Robotics Market:

- ABB Limited

- DAIHEN Corporation

- Denso Corporation

- Epson America Incorporated

- Fanuc Corporation

- Kawasaki Heavy Industries Limited

- Kobe Steel, Limited

- Kuka AG

- Mitsubishi Electric Corporation

- Yaskawa Electric Corporation

- Other Prominent Players

Market Segmentation Overview

By Type

- Articulated

- Cartesian

- SCARA

- Cylindrical

- Others

By Industry

- Automotive

- Electrical & Electronics

- Chemical Rubber & Plastics

- Machinery

- Food & Beverages

- Others

By Function

- Soldering & Welding

- Materials Handling

- Assembling & Disassembling

- Painting & Dispensing

- Milling, Cutting, & Processing

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Source: https://www.astuteanalytica.com/industry-report/industrial-robotics-market