Abstract

Switch-mode power supplies without transformers are typically used at lower voltage levels. But in some applications, new devices such as high voltage buck controllers can be used instead. They offer the beauty of a design without the cost and difficulty of using a transformer. They also offer high power conversion efficiency and enable high output voltages. In addition, this technology can be used for generating high negative voltages out of positive supplies.

Introduction

Switch-mode power supplies based on the buck (step-down) converter principle are widely used in all electronic applications. They do not require a transformer, just a simple coil to efficiently convert a high voltage to a low voltage. These converters are widely employed, and the setup is quite simple. Typical applications are for supply voltages up to 60 V and generating output voltages of up to 12 V. With higher supply voltages or higher desired output voltages, there are often limits to the availability of suitable converter integrated circuits.

Of course, voltage conversion with a switching regulator is also possible at much higher voltages, but these use converter topologies that are based on transformers, such as flyback or forward types, requiring a bulky and costly transformer.

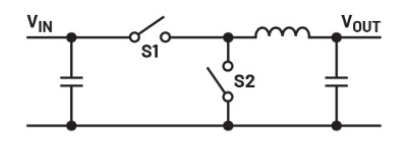

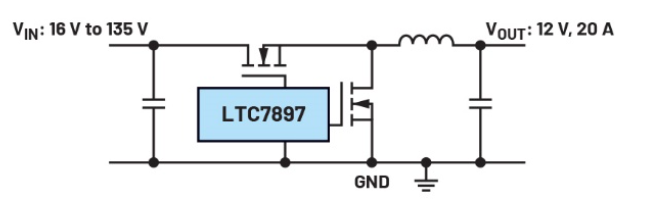

The two switches, S1 and S2, in Figure 1 are mainly responsible for the maximum possible input voltage range. However, the corresponding driver in a voltage converter IC must also be able to generate the high gate voltage required for the S1 switch. This voltage is the sum of the maximum supply voltage plus the threshold voltage required for the MOSFET. Thus, in addition to the MOSFET, the voltage converter IC must also be selected accordingly. Figure 2 shows the LTC7897 controller IC, which is designed for a supply voltage of up to 135 V (140 V abs max). The output voltage can also be very high when using this IC. It can be up to 135 V as long as it is lower than the input voltage.

With this high voltage buck controller, it is possible to convert from 100 V to 12 V. Because this design uses discrete switches, the MOSFETs can be selected for high currents. The circuit in Figure 2, for example, can generate a 20 A load current at 12 V.

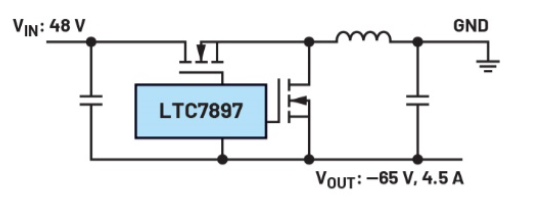

In addition to the voltage conversion example from Figure 2, in which a high voltage is converted into a low voltage, there is another scenario where a high positive voltage is available, and a negative voltage can be derived from it. A possible topology for this is a buck-buck controller in the inverting topology. This circuit does not require a transformer, but only a simple coil to generate a negative voltage from a positive input voltage.

An inverting buck-boost topology requires a voltage converter that offers special maximum voltage capability, as the regulator must be able to handle at least the available supply voltage plus the absolute of the negative output voltage generated. At 48 V V IN and the required negative 65 V V OUT , a voltage rating of the switch-mode power converter of at least 103 V is necessary. A switch-mode power supply with a high voltage rating is therefore particularly suitable for generating high, negative voltages.

Figure 3 shows the LTC7897 in the inverting topology to convert from a 48 V supply voltage to a –65 V output voltage.

Conclusion

For the operation of a switch-mode power supply at high voltages, a transformer-based topology does not necessarily need to be selected. With appropriate power converter ICs, such as the LTC7897, many applications can be operated without having to use complex and cost-intensive transformers.

About the Author

Frederik Dostal is a power management expert with more than 20 years of experience in this industry. After his studies of microelectronics at the University of Erlangen, Germany, he joined National Semiconductor in 2001, where he worked as a field applications engineer, gaining experience in implementing power management solutions in customer projects. During his time at National, he also spent four years in Phoenix, Arizona (U.S.A.), working on switch-mode power supplies as an applications engineer. In 2009, he joined Analog Devices, where he has since held a variety of positions working for the product line and European technical support, and currently brings his broad design and application knowledge as a power management expert. Frederik works in the ADI office in Munich, Germany.