This article covers the presentations of case studies at the “Annual Conference of Japanese Society for Artificial Intelligence, 2024″ attended by Murata Manufacturing (hereinafter, “Murata”) as well as the exhibits at their corporate booth with comments from the three members of the data & analytics department, who participated in the conference on the day of the event.

1. Participating in conferences and promoting the appeal of the practical application of data science

The Annual Conference of Japanese Society for Artificial Intelligence, 2024 (hereinafter, “JSAI 2024”) is a large-scale academic meeting on artificial intelligence in Japan. The conference was held from May 28 to 31 at ACT CITY Hamamatsu and was attended by around 3,790 people (including approximately 3,010 working professionals and 780 students).

Murata is actively applying data science to operations in a diverse range of fields. Higashi explained the purpose of Murata’s participation in JSAI 2024 as follows.

Higashi: “Even people who were familiar with the Murata company name were not really aware that we are putting data science including AI into practical use in a wide range of operations. Participating in JSAI 2024 created an opportunity for the many participating companies, university researchers, and students to learn more about our data science efforts. At the same time, we also wanted to obtain insights and learn by communicating with people outside the company.”

From right to left:

Higashi is in charge of data science in the manufacturing field and presented a case study on mathematical optimization at the conference.

Nakano is in charge of data science in the sales and marketing field and presented a case study on AI application at the conference.

Matsui is in charge of applying data science to new businesses and was responsible for handling visitors to the Murata booth at the conference.

2. Presenting case studies about data science initiatives

The company participated in an oral presentation in the industrial session, which was attended by 30 companies from various industries including electrical machinery, automobiles, pharmaceuticals, and other manufacturers, as well as telecommunications companies, various venture firms, etc.

With almost 100 people filling every available seat, Higashi and Nakano from the Data & Analytics Department each presented actual data science case studies that they had worked on. The details of their presentations are introduced below.

Data science case study: “Application Verification of Mathematical Optimization to Production Scheduling”

Higashi presented an application verification case study of mathematical optimization*1 for automating complex production schedule planning tasks at manufacturing sites and shared his experiences at each stage of the study.

Higashi: “The reason I chose a verification case study rather than a case study where data science was already in practical use is that I expected to hear opinions and obtain clues from those who watched the presentation as we make adjustments to introduce the optimization to our facilities. In fact, after the presentation, I had the opportunity to speak with people who are involved in data science at other companies and engage in the kind of deep discussion that can only happen in the field.”

*1 Mathematical optimization refers to the discovery of the optimal solution to reach a particular goal using mathematical techniques and algorithms. For example, it considers multiple variables and constraint conditions to derive a solution that maximizes or minimizes a goal. While machine learning requires training a system on a large volume of data, mathematical optimization finds the optimal solution based on a constructed mathematical model.

- Challenge: the task to create a production schedule relies on specific personnel. Human resource development takes time.

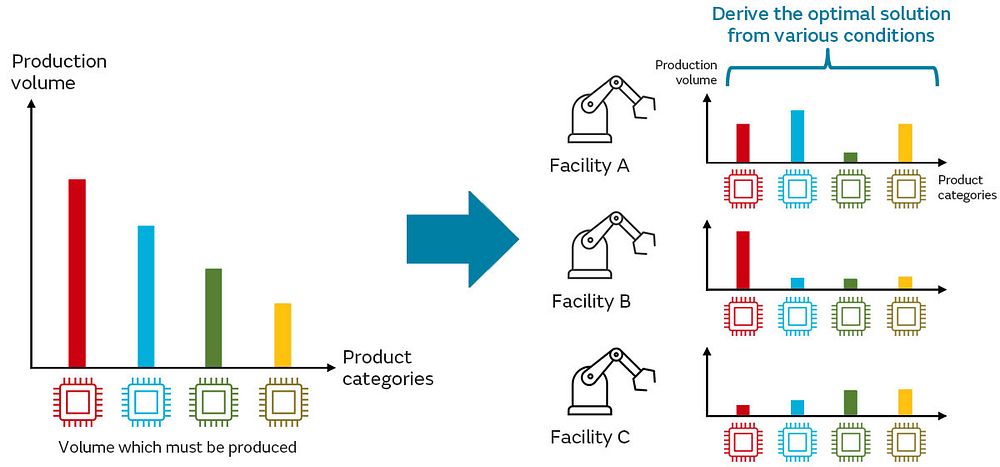

- Action: verify the applicability of mathematical optimization to the task of production plan creation which includes complex constraints. In particular, apply mathematical optimization to the problem of determining the amount to allocate to facilities.

The process leading to formulation and a feasible solution through close interaction and learning with the manufacturing site is shown below.

(1) Starting from a high degree of difficulty

During interviews with the manufacturing sites, there were no prior case studies of applying mathematical optimization, and Higashi himself was starting from a high school level of knowledge (linear programming).

Generally speaking, one of the challenging points of mathematical optimization is reducing the constraints and requirements that exist in actual operations to a mathematical formula.

Higashi: “In the interviews with the manufacturing sites, the requirements were complex and involved specialized terminology relating to the manufacturing process. At first, I was unable to grasp any of the specific details. At the same time, the main focus at the manufacturing sites was centered around the application of machine learning (ML), and there were no case studies about the application of mathematical optimization. In addition, as the person in charge of the technical verification, I myself had a materials background and experience in ML. However, this was my first time working with mathematical optimization, and I was unsure whether the problem could be solved with linear programming*2.”

*2 Linear programming is a method for finding the variable values that maximize or minimize the value of a linear function in a region that satisfies several linear inequalities. It corresponds to the objective of optimizing the target under certain restrictions. It graphically represents the region that satisfies the given inequalities and finds the variables that maximize or minimize the objective variable within the region.

(2) Detailed operational understanding and starting from small-scale trials

With the cooperation of people who are well-versed in the operations at the manufacturing sites, we were able to gain a detailed understanding of the operations to the point where we could describe them as mathematical expressions. In addition, while actual manufacturing sites produce a wide variety of products with many pieces of equipment, we started to formulate the problem from a small scale consisting of three products and three pieces of equipment.

Higashi: “There are many people at Murata who are interested in new technologies, and the people with deep knowledge of the on-site operations offered their cooperation in tackling this challenge. Reducing the constraints and requirements to a mathematical formula requires a detailed understanding of the on-site operations, and they patiently answered my questions using easy-to-understand terminology. At the same time, I was also learning about optimization from books and study sessions. I learned not only about optimization algorithms but also mastered techniques for reducing them to linear programming problems starting from small-scale trials.”

(3) Successfully formulating an equation that satisfies the operational requirements

While deepening our understanding of the site operational requirements, we came up with ways to combine various optimization techniques and proceed with the formulation. As a result, we successfully obtained an equation and a feasible solution that satisfied the minimum requirements. This knowledge was shared in the department and disseminated within the company.

Higashi: “Although I do not think that it is an efficient formula, we were able to achieve a formulation and feasible solution that satisfies the operational requirements. After finishing the technical verification of this project and disseminating information about this case study internally, other departments that were interested in mathematical optimization began contacting us seeking consultation.”

Color-coded constraint equations and codes*3

*3 Higashi hand-wrote the constraint equations in black and the code connections in red to organize the complex requirements and mathematical formulas (the image has been blurred due to the inclusion of confidential information).

As a result, automation through mathematical optimization was able to achieve a similar level of performance as a human-created production schedule, and the goal of exploring the possibilities of applying mathematical optimization to production planning tasks including complex constraints was achieved. The next challenge will be to build a maintenance system that can handle minor stoppages (short-time equipment stoppages due to sudden problems), changes in constraint conditions, and process changes. At the request of another plant, a project to apply this approach to their operations is currently underway.

AI application case study: “Automatic classification of inquiry response tasks utilizing natural language models”

Nakano explained how the company utilizes a proprietary system (hereinafter, the “response department suggestion engine”) to streamline the handling of requests and shorten the time to respond to customers by applying a natural language model to suggest the appropriate department to respond to survey requests and inquiries from outside the company.

Nakano: “While I believe that Murata has a strong image as a manufacturer of electronic components, I chose this theme because I wanted people to know that the company is working on data science in other areas as well. Furthermore, I want to convey that this initiative, which consisted of internal planning, modeling, and system development, did not simply end with a PoC (Proof of Concept) but was put into practical use in operations and is producing results.”

- Challenge: When customers or auditing organizations inquire about certification or pertinent management systems, for example, it takes time and effort to request the appropriate department to create a response and obtain an accurate response.

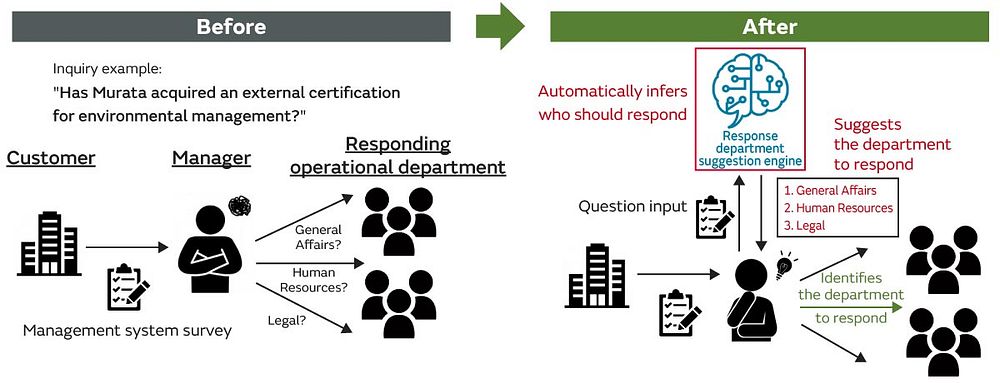

- Action: When a customer inquiry is entered into the template, the system automatically infers and suggests (Figure 2) the department that should respond using a highly accurate natural language model (automatically discriminates between Japanese and English). This shortens the time required for a response and streamlines operations.

Figure 2 Conceptual diagram of operational streamlining through the introduction of the response department suggestion engine

Three elements regarding how the response department suggestion engine operates and how it increases convenience and accuracy are shown below.

System operation

Our goal was to create a system that any employee can easily use. Users only need to write an inquiry question in the transcription template and save it to the input folder on the cloud server. The natural language model writes the inference result for the department that should respond to the template and automatically returns it to the output folder.

Language gate model

Based on prior research, it was discovered that using single language models tends to result in higher accuracy. Therefore, we developed a language gate model that automatically determines if an entered inquiry is in Japanese or English to increase accurac.

High-accuracy natural language model

Using a BERT*4 model, we successfully developed a model with an accuracy of over 85.0% for both Japanese and English models. In putting a natural language model into practical use in responding to customer inquiries, it was essential that we develop a highly accurate model

*4 BERT is an abbreviation of “Bidirectional Encoder Representations from Transformers” and refers to a model for natural language processing (NLP) announced by Google in 2018. The model is said to improve the ability to understand contextual expressions and provide greater versatility through a pre-trained model using bidirectional unsupervised learning.

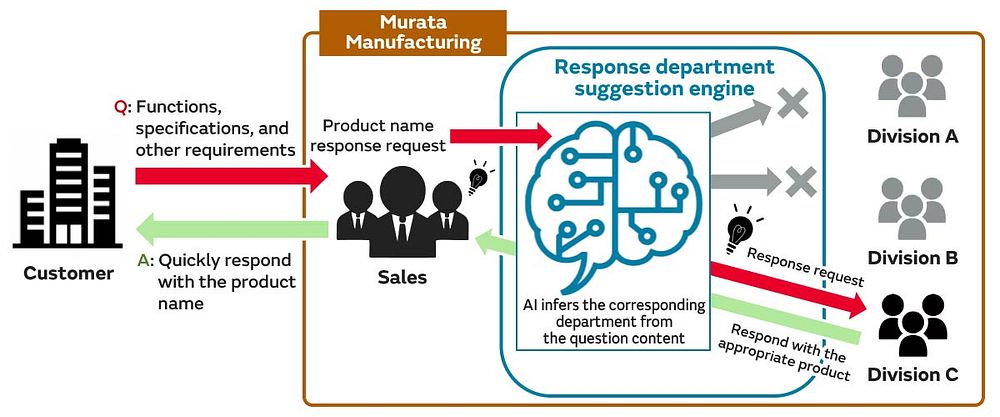

This system is also being horizontally deployed to similar business tasks and being applied to sales operations, as shown in Figure 3.

Murata handles many different types of products with varying specifications, and each product is managed by a different division. Therefore, the company utilizes the response department suggestion engine to identify products that meet customer requirements to save labor and accelerate operations that respond to customers.

Nakano: “Because Murata has many types of products and operations, it requires a significant amount of time and effort to reach the appropriate contact through manual effort. Such problems are still scattered throughout the company. My vision for the future is to serialize the response department suggestion engine and deploy it as a system that can support operations to create responses in each field in an integrated manner. In addition, I would like to work on improving the usability by simplifying the input work and automating the inquiry actions based on the output content.”

3. Wide-ranging and bottom-up activities attract attention at the company exhibition

Posters and products introducing case studies of the company’s data science initiatives were on display at the company exhibition booth.

In addition to displays of electronic components and communication modules, demonstration units for hands-on experience of sensors and healthcare products were also available.

Matsui: “Most of the people who stopped by our booth had no idea that Murata was working on data science. It was great that they were able to learn about our wide range of activities. In addition, many people think of Murata’s corporate culture as being top-down, but they were surprised to learn that there are actually many bottom-up initiatives. Furthermore, we have joint research agreements with universities to engage in research and development of healthcare-related products. That fact seemed to be of great interest to students conducting research in this field, and there was a lot of Q&A on this topic.”

4. Engaging in more concrete and deeper communication in the future

Finally, the three data scientists shared their impressions about participating in JSAI 2024 and their future plans for the conference.

Higashi: “Perhaps it was because I spoke about the process of learning about techniques that had never been applied before within the company during my oral presentation, but I received questions from people at other companies about in-house training. I felt that in order to increase the number of talented people involved in data science going forward, we need to do more to publicize the need for systems for improving in-house training and catching up with the latest techniques. In addition, the technical explanations provided in this recent case study presentation were a little too abstract. Next time, I would like to engage in a more fulfilling Q&A and discussions with external companies by reinforcing the specifics of the technical aspects.”

Nakano: “I gave an oral presentation for the first time at JSAI 2024. To be honest, I thought that giving a presentation would be a significant hurdle to clear. However, when I actually tried it, I realized how important it is to externally share information. The Data & Analytics Department has accumulated many results, so I hope to present more concrete case studies going forward. Ideally, companies such as ours would present concrete case studies at conferences, enabling an exchange of opinions and mutual improvement of techniques, which would lead to the promotion of DX throughout the manufacturing industry.”

Matsui: “I think that being able to publicize Murata’s data science initiatives, which were almost completely unknown, was a great success. At this conference, we focused on making people aware of the breadth of Murata’s initiatives, and I would like to speak about each of them in more detail in the future. I hope that linking to the oral presentation materials and the booth exhibitions will lead to deeper communication with the visitors.”