Introduction

The fast-growing wireless earbud market was originally jumpstarted by mobile video and subsequently fueled by wireless stereo and fitness monitoring. The potential for innovation in hearable applications appears to be endless, as seen by new features such as biometrics, voice recognition, and noise cancellation. The miniature hearable system is comprised of the two earbuds and their charging cradle (Figure 1). All three self-contained, battery-powered subsystems require careful partitioning, tight space utilization and efficient use of the limited battery charge available. How do you enable more functionality while delivering power more efficiently in a tight space for a longer time? This article presents an innovative power management system that delivers power in a very small space, while enabling longer battery life for each of the miniaturized elements of the hearable system.

The Hearable System

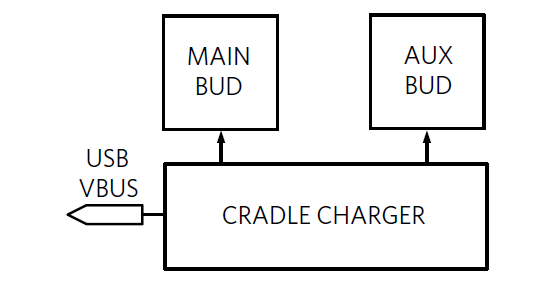

Figure 2 illustrates the hearable system, complete with earbuds and a cradle. The cradle receives power via the USB 5V VBUS supply which charges the battery. When the buds are in place, the cradle powers the two buds, enabling their recharge even when untethered from VBUS. The main bud packs the electronics necessary for processing, wireless connection, audio amplification and sensing, while the auxiliary bud powers the most basic functions of connection and audio.

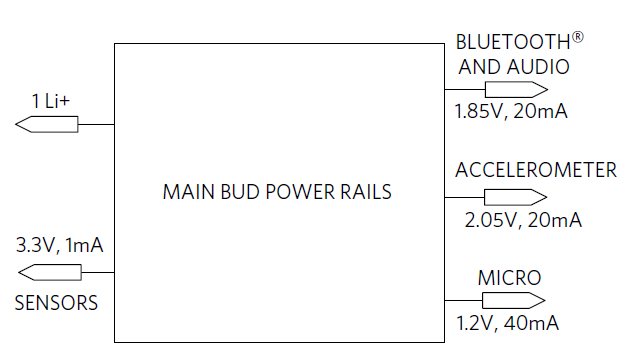

Earbud manufacturers currently specify 3 to 5 hours of playtime at 40% to 50% volume and 10 days of standby time with a 50mAh battery. On the other hand, the requirement for the cradle to support 5 charges while untethered puts its battery capacity at around 500mAh. The specifications are getting tougher over time, requiring innovative solutions that deliver more functionality for a longer time in a limited space. Main Bud Power Rails The block diagram in Figure 3 illustrates the rails necessary to power the main bud. Allowing for power conversion inefficiencies in a worse-case scenario, the bud may draw as much as 80mA with all the loads simultaneously active. In this case, a 50mAh battery would last only a bit more than a half hour. For the battery to last 5 playtime hours at 50% volume, virtually all the blocks except Bluetooth and audio must be inactive. Clearly, this system needs tight power management to deliver to specification.

Similar considerations apply to the auxiliary bud and the cradle. Tight power management is required both in operation and standby states. Current solutions struggle to fulfill the space and battery life requirements. A solution that delivers more power in a smaller space is necessary to enable more complex, more ergonomic, and longer lasting hearable solutions.

Main Bud Power

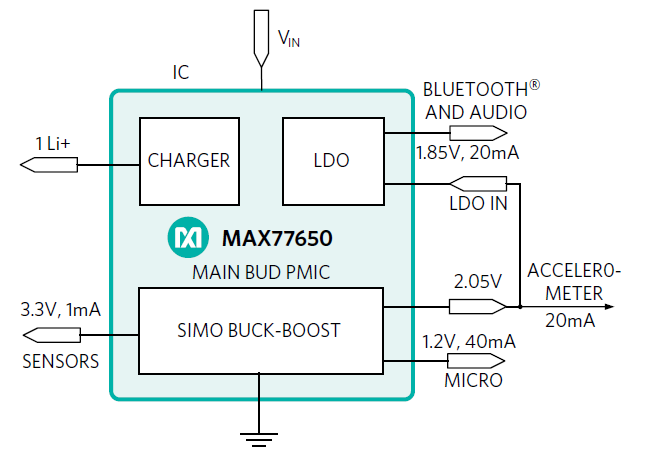

The power management IC (PMIC) in Figure 4 (MAX77650) integrates all the required functions into one chip. The small PMIC eliminates the wasted space associated with using multiple packages. A single-inductor multiple-output (SIMO) buck-boost regulator implements three efficient switching regulators utilizing a single inductor, which reduces the overall solution size. In addition, high-frequency operation allows the use of a small inductor, further minimizing the required space. One LDO is on-chip for noise-sensitive loads. For simplicity, the external passives are not shown.

Auxiliary Bud Power

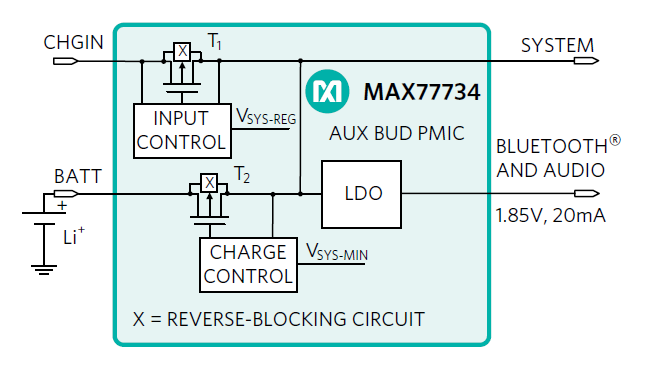

The PMIC in Figure 5 (MAX77734) integrates the essential functions for the auxiliary bud. The tiny PMIC’s linear battery charger implements Maxim’s Smart Power Selector circuitry to distribute power between the SYSTEM and the battery. The input control loop, in the presence of power to CHGIN, regulates the SYSTEM voltage to 4.5V (VSYS-REG). The LDO and the battery charger (transistor T2 and its associated control) are both powered from the SYSTEM. In the absence of input power, the battery powers the LDO and the system loads via T2. In low-power mode, the IC consumes only 4.5μA, which has practically no effect on the earbud’s required 10 days of standby time. In shutdown mode, the IC consumes less than 500nA from BATT.

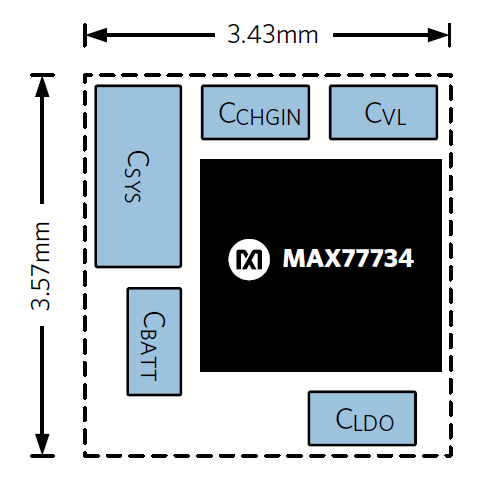

The solution layout in Figure 6 accounts for the active and passive components, except for three pullup resistors which are often integrated into the microcontroller. The total board space occupied is a mere 12.24mm2.

MAX77734

The small MAX77734 PMIC (2.23mm x 1.97mm x 0.5mm WLP) powers the auxiliary bud, requiring minimal (best-in-class) PCB space.

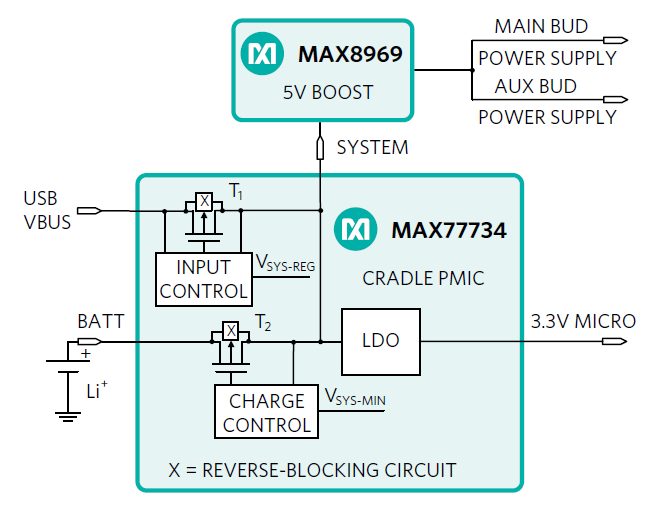

Cradle Power

Figure 7 shows the cradle power system solution. The MAX77734 implements the cradle charger and 3.3V microcontroller regulation, while the small and efficient MAX8969 boosts the SYS voltage to 5V for both the main and auxiliary buds.

The MAX77734 PMIC and the MAX8969 boost converter (1.25mm x 1.25mm WLP) power the cradle, again requiring minimal (best-in-class) PCB space. For additional design simplicity, the charger registers in the MAX77650 (main bud power) and MAX77734 (auxiliary bud and cradle) are identical, so the same set of firmware can be used for both.

Conclusion

A hearables set is a miniature system comprised of two earbuds and their charging cradle. The three self-contained, battery-powered subsystems pack increasingly more electronics into a very small space and must operate for several hours at a time. Although traditional approaches require tradeoffs in terms of functionality vs. electronics size, a new chipset helps solve the design constraints encountered with hearables devices. The MAX77650 with its SIMO architecture and the MAX77734 with its Smart Power Selector, together with the MAX8969 boost converter, efficiently deliver more power than before in an even smaller space. The burgeoning functionality in hearables now becomes manageable since we have the power solution to support it.