As electric vehicles (EVs) become increasingly popular, cells and battery testing have become an essential part of the development and manufacturing process. Cells and batteries are the heart of an EV, and testing them is necessary to ensure they are safe, efficient, and reliable. Without adequate testing, EVs could not be certified and sold. By understanding the importance of cell and battery testing in EVs, manufacturers can ensure their vehicles are of the highest quality. Cells and battery testing in EVs is a critical part of an EV’s maintenance schedule, as it can help to prevent battery failure and extend the life of the vehicle.

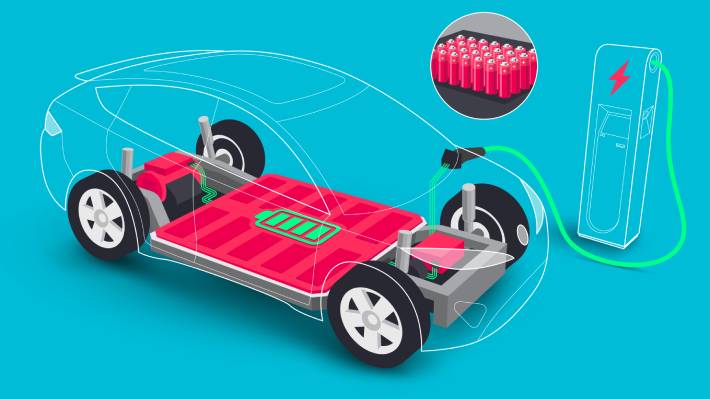

The cells and batteries used in EVs are the most important components of the vehicle. They are responsible for storing and providing power to the motor and other electrical components. Without cells and batteries, an EV would not be able to function properly. As such, testing them for quality is essential for the safety and performance of the vehicle. The most common types of cells and batteries used in EVs are lithium-ion, nickel-metal hydride, lead-acid and the most important thing when testing these batteries is to ensure that they are not overcharged or undercharged.

The cells in the battery should also be tested for resistance. This indicates how well the cells are able to transfer energy from the battery to the motor. If the resistance is too high, it can lead to a decrease in efficiency, which can decrease the range of the EV. The cells should also be tested for any signs of physical damage, such as cracks or bulges and the battery should also be tested for balance, which is the ability of the cells to charge and discharge at the same rate. If the cells are not balanced, it can lead to a decrease in efficiency. Testing for balance should be done regularly to ensure that the battery is able to hold its charge.

Overcharging can lead to a decrease in battery life and a decrease in the amount of energy stored while undercharging can cause the battery to become unstable and can lead to safety issues. The battery’s voltage and temperature should be monitored during charging and discharging, and it is important to keep the battery in a safe operating temperature range. The battery should also be tested for capacity, which is the amount of energy it can store. This is important for determining how much range the EV will have on a single charge. A capacity test should be done periodically to ensure that the battery is still able to hold its charge.

Each type has its own unique properties that require specific testing. For example, lithium-ion cells are known for their high energy density, but they can be volatile and can be damaged if not stored and charged properly. Nickel-metal hydride cells and lead-acid batteries, on the other hand, are more resistant to damage, but they have lower energy densities. The battery should be tested for its ability to withstand extreme temperatures. High temperatures can cause the battery to degrade quickly, which can reduce the range of the EV. On the other hand, low temperatures can cause the battery to become unstable and can lead to safety issues. Cells and battery testing in EVs is an important part of maintaining the vehicle.

Regular testing can help to identify any potential problems with the battery and ensure that it is operating properly. It can also help to extend the life of the battery and increase the range of the EV. It is important to follow the manufacturer’s instructions when testing the battery, as this can help to ensure that it is functioning as it should. Regardless of the type of cells and batteries used, manufacturers must conduct regular tests to ensure they are functioning properly.

This includes testing the cells and batteries for voltage, current, temperature, and charge/discharge cycles. All of these tests are conducted in a laboratory using specialized equipment, such as a battery test chamber. The tests are designed to simulate the conditions that the cells and batteries would experience in a real-world driving environment. In addition to the testing conducted in the lab, manufacturers must also conduct on-road tests to determine how the cells and batteries perform in real-world conditions. This includes tests such as range testing, acceleration testing, and braking testing.

All of these tests are necessary to ensure the cells and batteries are safe and reliable in all driving conditions. The results of cells and battery testing are critical for the safety and performance of EVs. If the cells and batteries are not tested properly, there could be serious consequences. For example, if the cells and batteries are not able to hold a charge properly, the EV may not be able to reach its maximum range, or worse, it may suffer from power loss during acceleration or braking.

By conducting regular tests and monitoring the results, manufacturers can ensure their EVs are as safe and reliable as possible. Cells and battery testing is an essential part of the EV development and manufacturing process. By understanding the importance of testing, manufacturers can ensure their EVs are of the highest quality and reliability. By conducting regular tests and monitoring the results, manufacturers can guarantee their EVs are safe and will perform to their maximum potential. Also all this comes with an important aspect of this process, which is the future of cell and battery testing for EVs.

The future of cell and battery testing for electric vehicles (EVs) is an important area of research and development, as the success of these vehicles depends on the reliability and performance of their batteries. Battery testing is a crucial part of the overall development process for EVs, as it involves assessing and validating the performance and safety of the cells and batteries used in the vehicles. The goal of battery testing is to ensure that the vehicle’s performance meets the required specifications and that the battery is safe and reliable over the long term.

In the future, battery testing for EVs will need to be more comprehensive and rigorous. In order to ensure the safety and reliability of the cells and batteries, it will be necessary to perform more extensive testing procedures that involve the use of advanced technologies and sophisticated strategies. This will include the use of high-precision instruments to measure the performance and safety of the cells, as well as the use of sophisticated machine learning algorithms to predict battery behavior.

In addition, testing procedures will need to be optimized for the specific application of the EV. For example, testing for commercial EVs may need to be different than testing for consumer EVs. This will require the development of specialized testing protocols and tools that are tailored to the specific application. As technology advances, the use of artificial intelligence (AI) and machine learning will become increasingly important in the development and optimization of battery testing procedures.

AI and machine learning can be used to analyze data from past tests to identify areas of improvement and to identify new testing protocols and strategies. This will enable researchers and engineers to develop testing procedures that are more tailored to the specific needs of the EV. In addition, the use of AI and machine learning will enable the development of autonomous battery testing procedures. This will allow tests to be conducted without the need for human intervention, which will improve the efficiency and effectiveness of the testing process.

The use of autonomous testing will also reduce the cost of testing and allow for more frequent and detailed testing. Finally, battery testing for EVs will need to be integrated with other components of the development process. For example, the testing of the cells and batteries used in the vehicles will need to be connected to the testing of other components, such as the motor, control system, and safety system. This will enable the development process to be more efficient and effective, as all components of the vehicle can be tested at the same time. In conclusion, the future of cell and battery testing for EVs is an important area of research and development. Battery testing must become more comprehensive and rigorous in order to ensure the safety and reliability of the cells and batteries used in the vehicles. This will involve the use of advanced technologies and sophisticated strategies, as well as the integration of testing with other components of the development process. With these advances, the testing of cells and batteries for EVs will become more efficient and effective, allowing for the development of reliable and safe vehicles.