Düsseldorf and Green Island, New York – Asahi Kasei and subsidiary Crystal IS have demonstrated their next- generation Klaran single chip UVC LED. It emits at 160 mW in the ideal germicidal range of 260-270 nm. Further, it sets a new record for single-chip device output in a commercial device. This achievement marks a significant 60% increase over prior Crystal IS devices. It retains the optimal wavelength for germicidal efficiency.

This higher output device will be used to accelerate the adoption of UVC LEDs. Further, it will hasten the widespread replacement of low-pressure mercury lamps. The new device will retain the Klaran compact 3.5 mm x 3.5 mm package and solder pad design. This is to allow backward compatibility with existing customer designs. Moreover, the higher output will allow UVC LEDs to meet the performance and cost targets. This targets are needed to expand into new applications in high-flow water and air treatment.

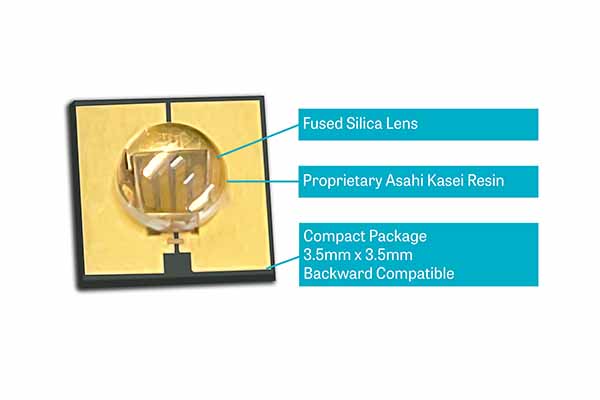

UVC LED design:

The new single-chip UVC LED design uses a rigid fused silica lens and a thin layer of proprietary UVC transparent resin. Further, this is developed by Asahi Kasei specifically to withstand the intense UVC output. Moreover, in contrast to soft molded lens, the rigid fused silica lens allows higher transmission of the UVC light. This ensures stable long-life performance and high-temperature stability. Asahi Kasei leveraged its long-running expertise in the field to develop the proprietary resin. However, this is after a careful and lengthy evaluation of commercially available adhesives resulted in no suitable candidate.

“This new high-output and long-life Klaran device is made possible by the strong cooperation between Crystal IS and Asahi Kasei innovation teams,” said Eoin Connolly, President and CEO. “With this new device in our portfolio, Klaran UVC LED devices make another significant step forward in replacing low- pressure mercury lamp technology and promoting the transition to non-mercury/non-ozone generating devices.”