Electric Vehicles (EVs) are emerging as the backbone of the future mobility system, revolutionizing battery performance and battery life. EVs comprise a key element, the batteries, and from time immemorial, batteries and heat have been companions. Overheating management is an essential factor to ensure the safety, efficiency, and life of the EV batteries.

Among other thermal management methods, electric heat tracing has been an effective and high-technology method of battery temperature control in extreme conditions.

Why Do We Require Battery Thermal Management?

Electric vehicle batteries are usually made up of Lithium-ion, which is very temperature-sensitive. Temperatures above the critical value can adversely affect battery performance, charge acceptance, and cycle life. Under extreme climates, reductions in ionic mobility can lead to reduced performance and reduced charging rates, ultimately to thermal runaway, a dangerous process culminating in self-destruction.

Therefore, thermal management is of utmost significance. Traditional cooling techniques, as good as they are under operation, may not work efficiently in extremely low temperatures, leaving room for electric heat tracing.

What Is Electric Heat Tracing?

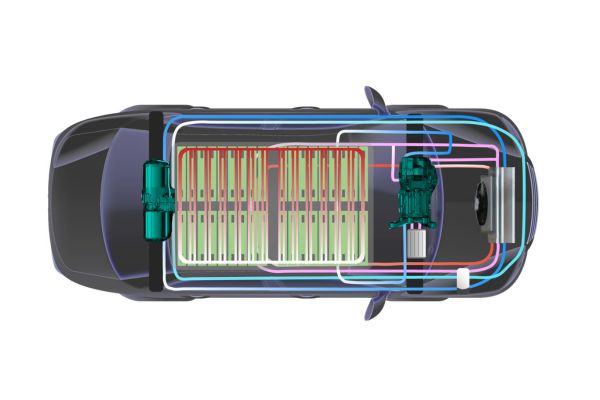

Electric heat tracing is a thermal management method used to control overheating in EV batteries. This process involves the use of electrically heated cables or mats that deliver consistent heat to maintain optimal temperatures. Electric heat tracing plays a pivotal role, especially in colder regions, where battery efficiency is affected due to low temperature conditions. It poses as an indispensable technique, offering pre-heating capabilities that ensure the battery is ready for operation before the vehicle is turned on, thus preserving performance and efficiency.

Principles And Components of Electric Heat Tracing

The electric heat tracing systems are composed of a variety of components, namely a heating element, sensors for detecting changes in temperature, controllers, and insulators. Let’s dive into some of these in detail:

- Heating element: A heating element generally represents a resistive cable, connected to the battery modules or coolant lines. It operates when the current flows across the cable, signaling for the heat to be generated uniformly.

- Temperature sensors: these sensors monitor real-time thermal data, then processed by control units that regulate the power supply based on optimized temperature.

Advanced features like self-regulating cables, automatically adjusting the output based on the surrounding temperature, improve efficiency. The integration of these components with the thermal management system of electric vehicles streamlines operations with onboard diagnostic tools.

One of the main benefits offered is the flexibility of heat tracing designs, which allows them to integrate with vehicle battery packs without extra alterations, allowing manufacturers to enhance performance without reengineering existing battery systems.

Advantages Over Traditional Heat Management Systems

Unlike traditional heating methods, electric heat tracing provides quick responses. It provided immediate heat transfer, unlike systems that need warm-up time and complicated plumbing, significantly reducing system latency. Additionally, this method can be scaled efficiently to a diversity of vehicles, from passenger cars to commercial trucks. This method enables efficient use of energy for localized heating, targeting only cold spots without the requirement of heating the complete system.

Furthermore, an electric heat tracing system doesn’t require much maintenance, with minimal moving parts and no fluids requiring timely replacements. This powerful structure enables system efficiency and reliability at a low cost. In addition to this, electric tracing components seamlessly integrate with renewable energy resources, pushing sustainability goals for the global adoption of EVs.

Applications of Modern EVs

Electric heat tracing is used not only in battery systems but also in peripheral components like coolant lines, charging ports, and power electronics. This is mainly because in coolant hoses, during cold weather conditions, their flexibility can be reduced, affecting their overall performance. By embedding heat tracing in these areas, manufacturers are enhancing the cold-start capabilities of EVs, mainly by warming up the battery pack during preconditioning.

With the advancement in battery pack densities, electric heat tracing provides the need to manage heat across different cell chemistries and designs. Therefore, their broad spectrum applications are limited not only for automotive use, but are also applicable in electric buses and rail systems, and stationary battery energy storage solutions.

Future Outlook

The future of electric heat tracing comprises lightweight composite materials, energy-efficient heating cables, and AI-based thermal management systems. These applications, combined with smart integration, including real-time data analytics, predictive diagnostics, and energy harvesting to create adaptive heating systems.

As solid-state batteries and next-generation chemistries emerge, the need for precise thermal control will only increase, placing electric heat tracing at the forefront of thermal innovation in EVs.

Conclusion:

Electric heat tracing has proven to be an efficient EV thermal management system. These systems ensure batteries and peripheral systems operate at optimal temperatures, without hampering safety performance, and the complete user experience. The growing adoption of this system into EVs enables a smarter and more resilient thermal system, supporting year-round operability in adverse climatic conditions. With the evolution of electric vehicles, this emerging technology is poised to grow exponentially, overcoming challenges in battery technologies in the future.