Abstract

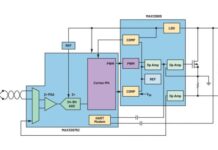

As ADAS and other high current applications are proliferating in automotive applications, the computing power of the related GPUs and ASICs continues to rise significantly. This puts additional pressure on the performance of voltage regulators for such demanding loads, where the currents increase and transients become larger and faster. Efficiency expectations continue to grow at the same time, while the load voltages decrease below 1 V for better thermal management and to enable advanced semiconductor processes with faster clocks. As low load voltage proportionally slows down the unloading transient and therefore causes a large increase in the bypassing capacitance, the volt- age tolerance and transient specs are also tightening. This calls for smaller and faster inductances in the multiphase voltage regulator to support such aggressive transients. The question is where patented ADI coupled inductors can support the fastest current slew rates, while simultaneously minimizing the current ripple and supporting high efficiency in a small solution size.

Introduction

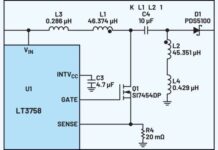

High current, low voltage applications frequently employ a multiphase buck converter topology for the voltage step down. This multiphase buck can utilize traditional discrete inductors (DL), as shown in Figure 1a, or coupled inductors (CL), as depicted in Figure 1b. In the case of CL, the windings are magnetically coupled, providing the advantage of current ripple cancellation.

Automotive ADAS applications face a challenge in maintaining tight regulation for GPU or ASIC rails within the 0.4 V to 1 V range, especially under fast transient conditions. A loading transient generally causes all phases to turn the switch- ing nodes VX high to VIN, so the inductor current in each phase ramps up with a slew rate (1), where VIN is input voltage, Vo is output voltage, and L is inductance value. An unloading transient typically causes all phases to turn low to GND and the inductor current ramps down (2). Given the low output voltage value VOUT < 1 V and assuming that the input voltage is typically 5 V or even higher, it is easy to see from the comparison of equations 1 and 2 that the unloading transient creates the main problem as there is only a small voltage to ramp the current down.

Read the full article here