It is said to be an old story when one rolled across with an Electric Vehicle (EV) and then haunted understanding – what if my car gets discharged or the battery runs out. Yeah quite similar like any portable device gadget which uses a single li-ion battery, automobile industry years back planned to switch towards a greener and cleaner future by introducing electric powered vehicles named popularly today as Electric Vehicles or EVs. With right policies, technologies, ecosystem and talent pool, EVs are all set to screech across the black pitch turfs. But in this evolution or say revolution of EVs, battery is the most important part of EVs as it helps the clean vehicle roll and generate considerable power. Same goes with hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and all-electric vehicles (EVs). Battery is the one of the most important and still a costly deal for carmakers.

EVs Battery Technology

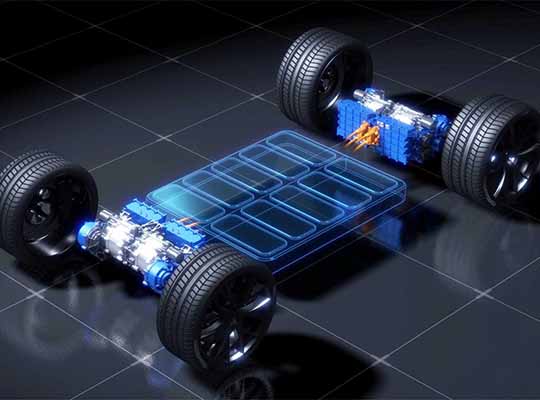

Critically EV batteries tend to ‘discharge’ while driving and even charging the batteries. Hence, when done to and fro and for many times it puts immense pressure into the batteries stating their longevity and their capacity to withhold in a longer period. Perhaps, this also affects the range and time needed between each journey to charge. Most manufacturers have a five to eight-year warranty on their battery. However, the current prediction is that an electric car battery will last from 10 – 20 years before they need to be replaced. How a battery and the car’s electric motor work together is surprisingly simple – the battery connects to one or more electric motors, which drive the wheels. When you press the accelerator the car instantly feeds power to the motor, which gradually consumes the energy stored in the batteries. Electric motors also work as generators, so when you take your foot off the throttle the car begins to slow down by converting its forward motion back into electricity – this happens more strongly if you hit the brakes. This regenerative braking recovers energy that would otherwise be lost, storing it in the battery again and so improving the car’s range.

Types of Energy Storage Systems

- Lithium-Ion Batteries

Lithium-ion batteries are currently used in most portable consumer electronics such as cell phones and laptops because of their high energy per unit mass relative to other electrical energy storage systems. They also have a high power-to-weight ratio, high energy efficiency, good high-temperature performance, and low self-discharge. Most components of lithium-ion batteries can be recycled, but the cost of material recovery remains a challenge for the industry. Most of today’s PHEVs and EVs use lithium-ion batteries, though the exact chemistry often varies from that of consumer electronics batteries. Research and development are ongoing to reduce their relatively high cost, extend their useful life, and address safety concerns in regard to overheating.

- Nickel-Metal Hydride Batteries

Nickel-metal hydride batteries, used routinely in computer and medical equipment, offer reasonable specific energy and specific power capabilities. Nickel-metal hydride batteries have a much longer life cycle than lead-acid batteries and are safe and abuse tolerant. These batteries have been widely used in HEVs. The main challenges with nickel-metal hydride batteries are their high cost, high self-discharge and heat generation at high temperatures, and the need to control hydrogen loss.

- Lead-Acid Batteries

Lead-acid batteries can be designed to be high power and are inexpensive, safe, and reliable. However, low specific energy, poor cold-temperature performance, and short calendar and cycle life impede their use. Advanced high-power lead-acid batteries are being developed, but these batteries are only used in commercially available electric-drive vehicles for ancillary loads.

- Ultracapacitors

Ultracapacitors store energy in a polarized liquid between an electrode and an electrolyte. Energy storage capacity increases as the liquid’s surface area increases. Ultracapacitors can provide vehicles additional power during acceleration and hill climbing and help recover braking energy. They may also be useful as secondary energy-storage devices in electric-drive vehicles because they help electrochemical batteries level load power.

- Recycling Batteries

Electric-drive vehicles are relatively new to the U.S. auto market, so only a small number of them have approached the end of their useful lives. As a result, few post-consumer batteries from electric-drive vehicles are available, thus limiting the extent of battery-recycling infrastructure. As electric-drive vehicles become increasingly common, the battery-recycling market may expand.

Widespread battery recycling would keep hazardous materials from entering the waste stream, both at the end of a battery’s useful life and during its production. Work is now under way to develop battery-recycling processes that minimize the life-cycle impacts of using lithium-ion and other kinds of batteries in vehicles. But not all recycling processes are the same:

- Smelting: Smelting processes recover basic elements or salts. These processes are operational now on a large scale and can accept multiple kinds of batteries, including lithium-ion and nickel-metal hydride. Smelting takes place at high temperatures, and organic materials, including the electrolyte and carbon anodes, are burned as fuel or reductant. The valuable metals are recovered and sent to refining so that the product is suitable for any use. The other materials, including lithium, are contained in the slag, which is now used as an additive in concrete.

- Direct recovery: At the other extreme, some recycling processes directly recover battery-grade materials. Components are separated by a variety of physical and chemical processes, and all active materials and metals can be recovered. Direct recovery is a low-temperature process with minimal energy requirement.

- Intermediate processes: The third type of process is between the two extremes. Such processes may accept multiple kinds of batteries, unlike direct recovery, but recover materials further along the production chain than smelting does.

Separating the different kinds of battery materials is often a stumbling block in recovering high-value materials. Therefore, battery design that considers disassembly and recycling is important in order for electric-drive vehicles to succeed from a sustainability standpoint. Standardizing batteries, materials, and cell design would also make recycling easier and more cost-effective.

EVs and the Indian Scenario

The number of EVs on the road have also been steadily increasing, and in 2019-20, the number of EVs on the road stood at 155,400 growing at around 20 percent year-on-year. Government policies like the Faster Adoption and Manufacturing of (Hybrid &) Electric Vehicles in India (FAME) which provide subsidies for EV production and charging infrastructure are a welcome fillip. Phase II of the scheme has an outlay of INR 10,000 crore ending this year for creating more demand for EVs. The 2019-20 budget announcement for tax subsidies for loans on EVs is again aimed at proliferating new forms of automobiles. Broadly, there is a renewed interest by the public in owning an EV considering high fuel prices in the country, which in turn makes most goods more expensive and contributing to an overall inflation in the country. A recent survey showed that 66 percent of the respondents were willing to go electric and 53 percent of them were strongly willing to purchase an EV.

Challenges for Lithium

Lithium extraction is very intensive and harmful to the environment. There is a lot of documentation across the world on the discharges from lithium extraction which seep into water sources and damage natural ecology. Towards more sustainability, India also needs to step up battery recycling capabilities. Though the Indian government has updated its e-waste management policies in 2018, the rules do not cover lithium batteries and its recycling guidelines only apply to lead-acid batteries. The enforcement of these rules is difficult due to poor e-waste generation rates and most reclamation takes place informally. There is US $1 billion opportunity for the private sector to chip in for reclaiming lithium batteries.

It will be prudent for India to invest in research into alternative battery technologies using different metals. Aluminium, sodium, and zinc based batteries have emerged as viable alternatives to lithium ones. Though aluminium batteries may be more advantageous from an Indian perspective. India is the fourth largest producer of aluminium and production has been steadily increasing. Aluminium is also cheaper than lithuim as a metal and cut costs of EVs. Aluminium batteries have shown that that they have more energy density than lithuim batteries which translates to longer range for EVs. This is primarily due to aluminium’s valency of +3 compared to lithium’s +1 and ion exchange is more efficient. There are mainly two types of batteries with this metal—aluminium ion (which are rechargeable) and aluminium air (which are non-rechargeable). Both have challenges with shelf life and more research in materials sciences are needed for better designs. Industry, academia, and government must come forward with an extensive policy to promote alternative batteries for sustainable EVs.

Policy on Advanced Battery Tech

The government will adopt an integrated approach and come out with a policy to make India self-reliant in the area of advanced battery technologies to power electric vehicles and other applications, Union Minister Nitin Gadkari said earlier this year. The government will adopt an integrated approach and come out with a policy to make India self-reliant in the area of advanced battery technologies to power electric vehicles and other applications, Union Minister Nitin Gadkari said. “So far work is happening in silos in the area of alternative fuel. We will now work in an integrated and concerted manner bringing together the best technologies. We will also focus on economic viability…We need a policy in this regard and for it we have decided to take an integrated approach,” Gadkari told .

He said scientists, academia and industry can together harness green hydrogen-based energy through water, for it being a cost effective and easily available mode in the country. He indicated towards the lowering costs of solar power in India, which can help energise other modes of fuels.

“So far work is happening in silos in the area of alternative fuel. We will now work in an integrated and concerted manner bringing together the best technologies. We will also focus on economic viability…We need a policy in this regard and for it we have decided to take an integrated approach,” Gadkari told .

He said scientists, academia and industry can together harness green hydrogen-based energy through water, for it being a cost effective and easily available mode in the country. He indicated towards the lowering costs of solar power in India, which can help energise other modes of fuels. The resultant employment generation will be huge and vehicle scrapping policy under which initially one crore vehicles will go for scrapping will result in availability of cheaper aluminium, copper, rubber, steel and other products which will reduce the price of the components. After going through the presentations from different organisations on different technologies including Lithium-ion, metal-ion, Sodium Sulphur, Hydrogen, Iron Sulphur, Polymer Electrolyte Membrane Cell System, ZincGel, etc, Gadkari said, economic viability is the basis of any successful technology.