Abstract

There are multiple approaches to adding more intelligence to industrial systems, including edge and cloud artificial intelligence (AI) matched to sensors with analog and digital components. With the diversity of AI approaches, the sensor designer needs to consider several competing requirements, including latency for decision-making, network usage, power consumption/battery life, and AI models fit for machines. This article series focuses on the design of an intelligent AI wireless motor monitoring sensor, and answers key questions such as how can edge AI extend the sensor battery life? And what is the improvement in my system insights and decision-making? The sensor presented uses an edge AI algorithm to detect anomalous motor behavior, triggering machine diagnostics and maintenance, and enabling longer motor operating life.

Motor Health Monitoring

Condition-based monitoring (CbM) of robotics and rotating machines, such as turbines, fans, pumps, and motors, records real-time data related to the health and performance of the machine to enable targeted predictive maintenance, as well as optimized control. Targeted predictive maintenance, early in the machine life cycle, reduces the risk of production downtime resulting in increased reliability, significant cost savings, and increased productivity on the factory floor. CbM of industrial machines can utilize a range of sensor data, such as electrical measurements, vibration, temperature, oil quality, acoustic, magnetic, and process measurements such as flow and pres- sure. However, vibration measurement is the most common by far, as it can provide the most reliable indication of mechani- cal issues such as imbalance and bearing failure. This article introduces the Voyager4 evaluation kit (EV-CBM-VOYAGER4-1Z), a robust, low power, wireless vibration monitoring platform that enables designers to rapidly deploy a wireless solution to a machine or test setup. The Voyager4 sensor uses an edge artificial intelligence (AI) algorithm to detect anomalous motor behavior, triggering machine diagnostics and maintenance, and enabling longer motor operating life. This is Part 1 of a series of three articles documenting the Voyager4 sensor, which can be used as a template to accelerate design efforts and understand trade-offs in intelligent system design.

• Part 1 of this article series will introduce the Voyager4 wire- less condition monitoring sensor, including key elements of sensor architecture, hardware design, power profiling, and mechanical integration.

• Part 2 of this article series will focus on the software archi- tecture and AI algorithm. A complete system-level approach for AI model development and deployment on the Voyager4 is described.

• Part 3 of this article series will look at the practical imple- mentation of the AI algorithm and the different faults Voyager4 can detect such as imbalance, misalignment, and bearing defects.

Wireless Vibration Sensor Typical Operation

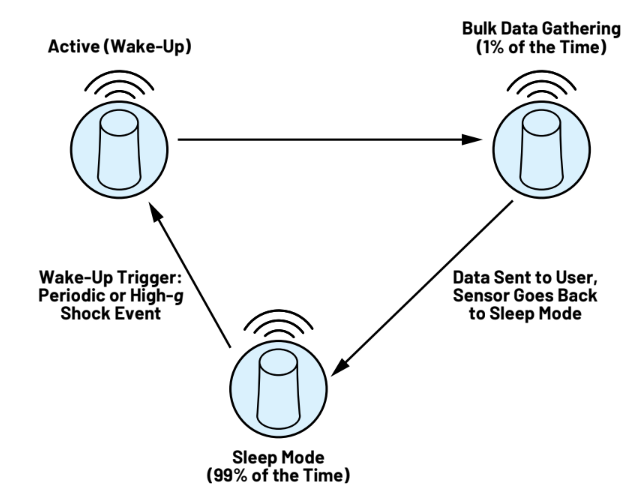

Wireless industrial sensors currently available on the market typically operate on very low duty cycles. The user sets the sensor sleep duration, after which the sensor wakes up and measures temperature and vibration, and then sends the data over the radio back to the user’s data aggregator. Commercially available sensors typically quote a 5-year battery life, based on one data capture per 24 hours, or multiple data captures per 24 hours. See Figure 1.

In most cases, sensors operate in sleep mode more than 90% of the time. The Voyager4 sensor will operate in a similar fash- ion but take advantage of edge AI anomaly detection (using the MAX78000 AI microcontroller) to limit the use of the radio. When the sensor wakes up and measures data, the data is only sent back to the user if the microcontroller detects an anom- aly in the data. By using AI at the edge, the battery life can be increased by at least 50% (see the Hardware System and Power Profiling section).

Voyager4 Sensor System Operating Principle

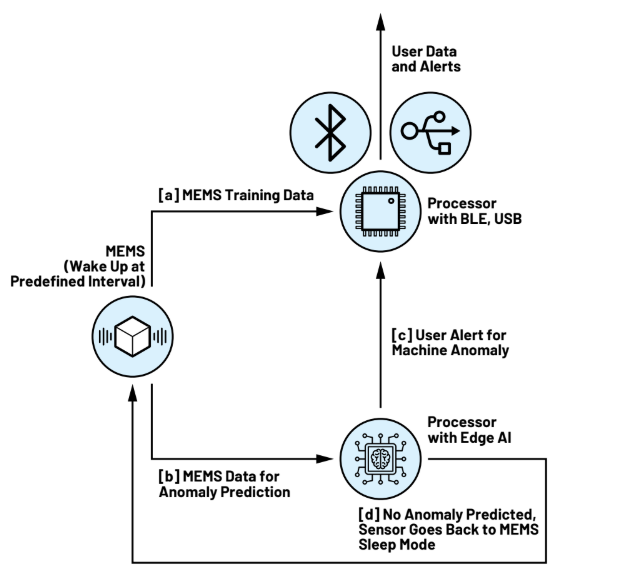

The Voyager4 sensor principle of operation is shown in Figure 2. The ADXL382 triaxial 8 kHz digital micro electronic mechanical systems (MEMS) is used to gather vibration data. First, the raw vibration data follows Path A to the MAX32666 Bluetooth® low energy (BLE) processor. The data can be sent to the user over BLE radio, or via USB. This raw vibration data is used to train an edge AI algorithm using MAX78000 tools.

Using the MAX78000 tools, the AI model is synthesized into C code. The edge AI algorithm is sent in a BLE over-the-air (OTA) update to the Voyager4 sensor and stored in memory using the MAX78000 processor with edge AI hardware accelerator. After this initial Voyager4 training phase, the ADXL382 MEMS data can follow Path B shown in Figure 2. The MAX78000 edge AI algo- rithm will predict faulty or healthy machine operation based on the vibration data gathered. If the vibration data is healthy, then there is no need to use the MAX32666 radio. The Voyager4 sen- sor operation can follow Path D shown in Figure 2, where the MEMS returns to sleep mode. However, if faulty vibration data is predicted, then Path C is followed, with a vibration anomaly alert sent to the user over BLE. Part 2 of this article series will explain this edge AI implementation in more detail.

Read the full article here.