As a proud Gold Sponsor of IPC’s Integrated Electronics Manufacturing & Interconnections (IEMI) 2023, advanced materials innovator Indium Corporation is pleased to exhibit innovative materials for e-Mobility and share technical expertise in Pune, India on August 3.

A strong supporter of the Make in India campaign, Indium Corporation’s involvement in IEMI 2023 is further evidence of its commitment to serving India’s growing electronics market now and into the future.

“With our facility in Chennai, Indium Corporation is well positioned to support regional demand for consumer and infrastructure electronics, such as EV manufacturing, mobile, 5G, and semiconductors,” said Senior Country Sales Manager Damian Santhanasamy. “We look forward to serving the Indian electronics market, not only with our innovative materials, but by providing local technical expertise.”

Additionally, Associate Director for Global Technical Service & Application Engineering Jonas Sjoberg will participate in an expert panel discussion titled Importance of Electronics in Electric Vehicles. Sjoberg has more than 25 years of technical experience in the electronics industry, including developing and deploying leading-edge designs and processes for packaging and assembly managing research and development projects and facilities; and serving as technical advisor to internal and external design, development, and manufacturing sites worldwide.

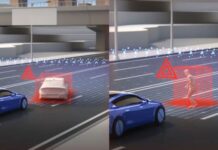

With its significant automotive industry expertise and an award-winning portfolio of proven products, Indium Corporation will feature its Rel-ion suite of electrical, mechanical, and thermal solutions which are designed to be reliable, scalable, and proven materials to reduce electric vehicle (EV) manufacturers’ time to market. More than three million EVs are currently on the road with Indium Corporation’s Rel-ion products.

Rel-ion material solutions deliver reliability by:

- Eliminating non-wet opens and head-in-pillow defects

- Preventing dendritic growth by meeting stricter surface insulation resistance requirements

- Preventing solder delamination with precise bondline control and increased creep and fatigue resistance

- Reducing hot spots-induced voiding through improved thermal efficiency