Abstract

Stepper motors are vital in precision applications where there is a need for smooth movement and high resolution positioning. Recognizing the differences between fullstepping, halfstepping, and microstepping control is essential for meeting these requirements. This article closes the knowledge gap by summarizing the basics of microstepping.

Introduction

Stepper motors are widely used in industrial, medical, and 3-axis positioning system applications such as 3D printers and computer numerical control (CNC) machines, due to their precision and relatively simple control schemes. Although AC motors and brushless DC motors can obtain high precision, stepper motors have the additional advantage of high precision while operating with openloop control and having high torque at low velocity. Additionally, stepper motors are often more cost-effective and less complex than servo motors. Unlike brushed DC motors, stepper motors can hold their position with high torque.

Microstepping is highly useful in stepper motor control by allowing the motor to move by smaller increments, resulting in a significant increase in the number of discrete positions per revolution and a subsequent decrease in motor noise and vibration. Analog Devices’ Trinamic Motion Control has stepper motor driver ICs, board-level modules, and complete solutions that are capable of operating stepper motors with up to 256 microsteps.

Stepper Motor Basics

Motor Construction

A stepper motor, frequently referred to as a stepper, consists of a magnetic rotor and stator coils. Hybrid 2-phase steppers have a rotor with two magnetic cups, each with typically 50 teeth as shown in Figure 1. These magnets have opposite magnetic polarity and are physically offset from each other. The stator consists of two coils of wire placed in multiple positions around the cen- tral rotor. Energizing each phase in sequence causes the motor to rotate.

Permanent magnet rotor.

Operation

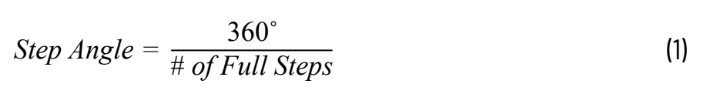

A stepper motor moves in discrete steps by dividing a full rotation into equidistant steps. For instance, a stepper motor with 200 discrete positions per revolution of the motor will have a 1.8° step angle. The step angle is derived from dividing the 360° of a revolution by the number of full steps.

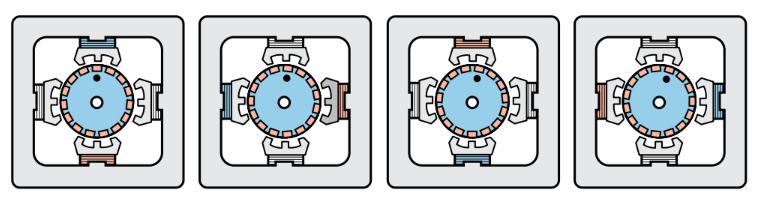

As shown in Figure 2, when current is applied to the motor’s coils, a magnetic field is produced that attracts or repels the permanent magnet rotor, and the rotor will rotate to align with this magnetic field. To keep the motor rotating, each coil must be alternately energized to keep the magnetic field ahead of the rotor.

Fullstepping and Halfstepping

To better understand the stepping behavior of a stepper motor, we will evaluate a simplified 2-phase stepper motor model with one magnetic pole-pair as shown in Figure 3.

Read the full article here.