The semiconductor industry is focused on developing smaller, faster, and more efficient chips, a quest that complicates the design and verification processes. As chip size decreases, the number of components increases, intensifying verification challenges and adding pressure to meet faster product timelines. Advancements in AI, 5G, IoT, and high-performance computing demand powerful, energy-efficient, and reliable chips. This shift to smaller nodes complicates design, as more logic gates fit into tighter spaces, making verification more intricate and time-consuming. Additionally, 5G drives demand for chips with higher data speeds, fostering innovation in edge computing and smart cities. The growing IoT ecosystem requires specialized, low-power semiconductors, compelling companies to balance efficiency, performance, cost, and security.

Challenges in Modern Chip Design Verification

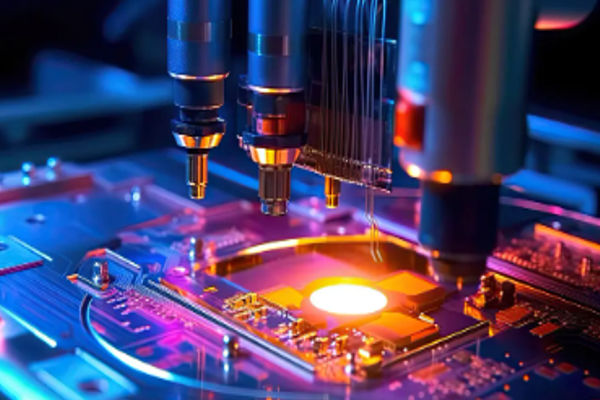

In today’s fast-paced technological landscape, Chip Design Verification is essential for ensuring the functionality, reliability, and security of integrated circuits. As the complexity of chips increases, verification teams face significant challenges, including the integration of diverse components, extensive functional verification, power efficiency assessments, and heightened security requirements. With designs advancing to smaller nodes (7nm, 5nm, 3nm, and beyond), the push for energy-efficient devices has made power management a critical aspect of chip design. Verifying the correct operation of various power modes and optimizing power consumption adds another layer of complexity. Many modern chips also incorporate both digital and analog components, necessitating specialized tools and expertise to verify the interactions between these domains. As designs become more intricate and often include multiple subsystems, verifying the entire system’s functionality is increasingly challenging. The competitive nature of the semiconductor industry further amplifies this pressure, as faster product cycles demand that verification teams complete their tasks quickly without sacrificing quality. Ensuring a low defective parts per million (DPPM) rate becomes more difficult with complex designs, necessitating more comprehensive verification strategies. Despite these challenges, emerging trends are enhancing verification practices.

Innovations in Chip Design Verification

To tackle the challenges in chip design verification, the semiconductor industry is increasingly adopting a range of innovative methodologies and tools. Advanced simulation techniques are essential, utilizing high-performance simulators and parallel processing to manage large, complex designs effectively. Emulation and FPGA prototyping play a crucial role in enabling faster hardware-assisted verification, particularly for system-level validation, allowing teams to identify issues early in the design cycle. Formal verification has gained prominence by employing mathematical methods to ensure the correctness of critical design elements, providing exhaustive coverage that traditional simulation might miss. Meanwhile, the integration of machine learning and AI into the verification process enhances test generation and coverage analysis, helping to identify patterns and potential issues that human engineers may overlook. Additionally, mixed-signal verification tools are becoming increasingly sophisticated, adeptly handling both digital and analog components for comprehensive testing. As the reliance on pre-verified IP blocks grows, methodologies for efficient integration and verification of these components within larger systems are becoming more vital. Together, these advancements are reshaping the landscape of chip design verification, enabling teams to navigate its complexities with greater confidence.

The Need for New-Age Design Verification Strategies

The need for new-age design verification strategies is increasingly evident in the semiconductor industry. Modern verification approaches leverage a combination of methodologies, including simulation for detailed analysis, emulation for faster hardware-assisted verification, and formal verification to mathematically prove design correctness. This multi-faceted strategy allows verification teams to balance speed, coverage, and rigorous validation. Rigorous coverage metrics are essential for quantifying the completeness of verification efforts, encompassing code coverage, functional coverage, and toggle coverage. Advanced tools help track progress and identify gaps, ensuring no critical areas are overlooked. Automated regression testing is vital as designs evolve, involving the execution of predefined tests after each change to quickly flag any regressions and maintain design integrity. Power-aware verification is crucial for ensuring correct operation across various power modes, simulating designs under different power conditions to verify functionality and catch issues like power sequencing errors. Lastly, system-level verification tests the entire chip as a unified system, validating functionality in real-world scenarios and helping to identify integration issues. Together, these strategies enhance the robustness of chip design verification in an increasingly complex landscape.

The Role of Specialized Engineering Partners

As chip design verification becomes increasingly complex, many semiconductor companies are turning to specialized engineering partners to augment their capabilities. These partners bring expertise in cutting-edge verification methodologies and tools, helping companies navigate the challenges of modern chip design. At Quest Global, we stand out as a comprehensive solution provider in the semiconductor industry. Our capabilities span the entire chip development lifecycle. We develop specifications and system-level designs, laying the foundation for robust chip architectures. From micro-architecture specifications to RTL development and verification, we ensure seamless integration of all design elements. In addition, we also offer comprehensive functional verification, low power design verification, and FPGA emulation services to ensure design integrity. Our team provides test architecture, MBIST insertion, and ATPG pattern generation, enhancing the testability of your designs. We handle floor planning, placement, timing optimization, and power analysis, optimizing your chip’s physical implementation. We offer expertise in analog and mixed-signal design, including SerDes, PMU, and RF layouts, catering to diverse design requirements. We map client SoCs/ASICs to FPGA platforms for hardware and software validation, accelerating the verification process. Our services include conducting validation, device characterization, and qualification, ensuring your chip meets all specifications. Our experience with advanced nodes (with over 55% of our silicon engineers working on 7nm or later technologies) and our track record of 460+ tape-outs from 65nm to 3nm make us a valuable partner for companies facing the challenges of modern chip design verification. At Quest Global, we’re committed to driving innovation and excellence in semiconductor engineering, helping our clients navigate the complexities of cutting-edge chip design and verification.