The global polymer 3d printing market size is estimated to hit around USD 9.90 billion by 2034 increasing from USD 2.86 billion in 2024, with a CAGR of 13.22%.

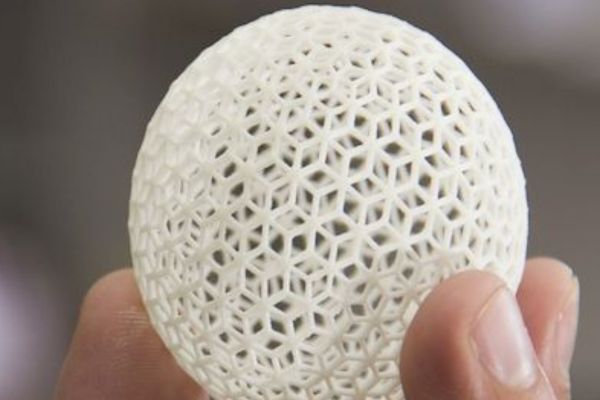

The Polymer 3D Printing Market is witnessing significant growth, driven by advancements in additive manufacturing technologies and the increasing demand for customized and complex polymer-based components. 3D printing, also known as additive manufacturing, enables the production of lightweight, durable, and intricate polymer structures used in industries such as aerospace, automotive, healthcare, and consumer goods.

The growing adoption of polymer 3D printing in prototyping, tooling, and end-use part manufacturing is fueling market expansion. Innovations in polymer materials, including high-performance thermoplastics and composite filaments, are further enhancing the capabilities of 3D printing technologies.

Polymer 3D Printing Market Key Takeaways

- North America dominated the global market with the largest market share of 41% in 2024.

- Asia Pacific is expected to witness rapid growth during the forecast period.

- By application, the healthcare segment held the largest share of the market in 2024.

- By application, the automotive segment is projected to expand at the fastest rate during the projection period.

- By material type, the thermoplastics segment dominated the market in 2024.

- By material type, the resins segment is likely to grow at the fastest rate in the upcoming period.

- By technology, the fuse deposition modeling segment led the market with a significant share in 2024.

- By technology, the stereolithography segment is anticipated to grow at a significant rate during the forecast period.

- By end-use, the prototyping segment dominated the market in 2024.

- By end-use, the production segment is expected to witness notable growth in the foreseeable period.

Impacts of Artificial Intelligence on Polymer 3D Printing Market

AI is revolutionizing the polymer 3D printing market by enhancing efficiency, precision, and material innovation. It enables generative design, optimizing complex structures for industries like aerospace and healthcare. AI-driven quality control ensures real-time defect detection, reducing material waste and improving reliability. Machine learning accelerates the development of advanced polymers with improved strength and sustainability.

AI-powered automation streamlines production workflows, optimizing print speeds, reducing costs, and enabling predictive maintenance to minimize downtime. It also enhances mass customization, allowing industries to create personalized medical implants, consumer goods, and fashion products. AI-driven supply chain optimization improves inventory management and supports decentralized manufacturing, making 3D printing more resilient to disruptions. Overall, AI is making polymer 3D printing smarter, faster, and more scalable for industrial and consumer applications.

Regional Outlook of Polymer 3D Printing Market

North America

North America leads the Polymer 3D Printing Market, driven by strong investments in research and development, a well-established aerospace and healthcare sector, and the presence of key market players. The U.S. government and private enterprises are actively funding additive manufacturing projects.

Europe

Europe is a key region for 3D printing innovation, particularly in Germany, France, and the UK. The region benefits from a strong automotive and industrial manufacturing base, as well as stringent environmental regulations that encourage the use of sustainable materials.

Asia-Pacific

The Asia-Pacific region is witnessing rapid growth, fueled by increasing adoption in China, Japan, and South Korea. The rise of smart manufacturing, government support, and expanding consumer electronics and healthcare sectors are contributing to market expansion. China, in particular, is investing heavily in 3D printing technology for industrial applications.

Latin America and Middle East & Africa

While these regions have a relatively smaller share of the global market, growing industrialization, infrastructure development, and the adoption of advanced manufacturing technologies are expected to drive polymer 3D printing adoption. Countries like Brazil and the UAE are showing increased interest in additive manufacturing.

Polymer 3D Printing Market Report Coverage

| Report Coverage | Details |

| Market Size by 2034 | USD 9.90 Billion |

| Market Size in 2025 | USD 3.24 Billion |

| Market Size in 2024 | USD 2.86 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 13.22% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Application, Material Type, Technology, End-use and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics of Polymer 3D Printing Market

Drivers

Need for Rapid Prototyping & Shift Toward Sustainable Practices

The growing demand for rapid prototyping is a key factor propelling the polymer 3D printing market forward. This technology facilitates quick prototyping, significantly reducing product development cycles. It enables the creation of complex and intricate geometries that are challenging to achieve through traditional manufacturing methods, making it highly desirable in the aerospace and automotive industries.

Automobile and aircraft manufacturers benefit from 3D printing by iterating and testing component designs before mass production, minimizing errors in the final product. Additionally, increasing environmental consciousness among businesses is driving the shift toward sustainable printing solutions. By enabling on-demand production, 3D printing reduces waste generation, aligning with global sustainability initiatives.

Restraint

Limitations in Materials

A major challenge for the polymer 3D printing market is material limitations. Certain polymers lack the mechanical properties needed for high-performance applications, such as temperature resistance and durability. This restricts their usability in various industries. Additionally, many 3D-printed components require extensive post-processing, including sanding and painting, to meet quality standards, increasing both time and cost. The high price of 3D printing equipment further limits market growth, particularly for small and medium-sized enterprises (SMEs), posing a significant barrier to widespread adoption.

Opportunity

Material Advancements

Innovations in material science are opening new avenues for the polymer 3D printing market. Research and development efforts are leading to the creation of advanced polymers with enhanced properties, broadening the scope of applications. The integration of cutting-edge technologies such as robotics and artificial intelligence is further optimizing the 3D printing process, reducing production time and increasing efficiency.

For instance, in April 2023, an international team of researchers from India, Singapore, Thailand, and Malaysia developed a method to use chitosan derived from terrestrial insects to produce eco-friendly polymer composite parts via 3D printing. Such innovations are expected to drive the demand for sustainable raw materials in the industry.

Application Insights

In 2024, the healthcare sector emerged as the dominant segment in the polymer 3D printing market, primarily due to its extensive use in manufacturing medical devices and prosthetics. The increasing demand for customized prosthetics further accelerated the segment’s growth.

The automotive industry is anticipated to experience the fastest growth in the coming years. Ongoing research and development in automotive manufacturing is driving the adoption of polymer 3D printing for rapid prototyping and component production. The ability to produce high-performance materials in minimal time makes it a preferred choice in the industry.

Material Type Insights

Thermoplastics led the polymer 3D printing market in 2024 and are projected to maintain strong growth due to their versatility and processability. These materials offer excellent flexibility, durability, and chemical resistance, making them suitable for various applications.

Resins, on the other hand, are expected to witness the highest growth rate in the near future. Their superior finish and ability to create intricate designs make them a popular choice in industries requiring high precision and aesthetic detail.

Technology Insights

Fuse Deposition Modeling (FDM) dominated the market in 2024, owing to its ability to rapidly prototype designs, making it widely used in the automotive, aerospace, and defense sectors.

Stereolithography (SLA) is expected to grow significantly due to its precision and ability to produce highly detailed components. Ongoing research and development efforts aimed at improving 3D printing technologies are further fueling the expansion of this segment.

End-use Insights

The prototyping segment accounted for the largest share of the polymer 3D printing market in 2024. The demand for rapid prototyping continues to rise as manufacturers require precise and efficient models before final production. Industries such as aerospace and automotive rely on 3D printing to develop intricate mechanical components with high accuracy.

The production segment is set to register notable growth in the coming years. The increasing demand for personalized products and efficient manufacturing processes is driving the adoption of 3D printing in production. Rapid manufacturing capabilities allow businesses to quickly adapt to changing market demands, further propelling the segment’s growth.

Polymer 3D Printing Market Companies

- Formlabs

- BASF

- ExOne

- Royal DSM

- Mark forged

- Nexa3D

- Stratasys

- Arkema

Recent Developments in Polymer 3D Printing Market

Advancements in Biodegradable and Recyclable Polymers

Companies are investing in the development of eco-friendly polymers for 3D printing to address environmental concerns. Materials like PLA (polylactic acid) and PHA (polyhydroxyalkanoates) are gaining traction for sustainable applications.

Launch of High-Speed and Large-Scale 3D Printers

Leading manufacturers are introducing faster, more precise, and industrial-scale 3D printers capable of producing large polymer components. These innovations are making 3D printing more viable for mass production.

Strategic Partnerships and Acquisitions

Major players in the Polymer 3D Printing Market are forming strategic collaborations and acquisitions to expand their market presence. Companies like Stratasys, 3D Systems, and HP are partnering with material developers and industrial manufacturers to enhance product offerings.

Integration of AI and Automation in 3D Printing

The use of artificial intelligence (AI) and machine learning (ML) in additive manufacturing is improving print accuracy, defect detection, and material optimization. AI-driven 3D printing solutions are expected to revolutionize the industry.

Expansion of 3D Printing in the Medical Sector

Recent advancements in biocompatible polymers have led to breakthroughs in medical applications, including custom prosthetics, implants, and dental devices. The ability to create personalized healthcare solutions is driving further investment in polymer 3D printing for medical applications.

The Polymer 3D Printing Market is poised for substantial growth, driven by technological advancements, increasing demand for customization, and sustainability efforts. While challenges such as high costs and material limitations persist, continuous innovations and expanding industrial applications are unlocking new opportunities. As governments and industries worldwide invest in 3D printing technologies, the market is set to experience transformative advancements, reshaping the future of manufacturing across various sectors.

Segments Covered in the Report

By Application

- Aerospace

- Automotive

- Healthcare

- Consumer goods

- Art and design

By Material Type

- Thermoplastics

- Resins

- Elastomers

- Composites

By Technology

- Fused deposition modeling

- Stereolithography

- Selective laser sintering

- Digital light processing

By End-use

- Prototyping

- Production

- Research and development

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa (MEA)