Aerotech, a leading manufacturer of motion control solutions and positioning systems, will be presenting its latest developments for motion control in photonics at Laser World of Photonics 2025 (24-27 June, Munich) in Hall A3.221. Visitors can expect an insight into high-performance demo systems, including high-precision positioning solutions and the AeroScriptPlus DrillOptimizer, which enables efficient and profile-specific optimisation of laser drilling.

The focus will be on solutions for laser micromachining, optical measurement processes and high-precision positioning tasks. “We are delighted to be represented at Laser World of Photonics again this year. This trade fair is one of the most important platforms for the photonics industry, and we have exciting innovations in store that will enable our customers to achieve greater precision and efficiency in their industrial processes,” emphasises Simon Smith, European Director Aerotech.

Optimisation of laser drilling with the DrillOptimizer

The AeroScriptPlus DrillOptimizer function, which is available in the Automation1-iSMC control configuration, enables profile-specific optimisation of the motion path and motion parameters for drilling vias with Aerotech’s AGV Galvo scanners. Several thousand to several million holes can be drilled efficiently.

The two-stage optimisation process of the DrillOptimizer first calculates the shortest movement path for the AGV galvo laser scan head (AGV-HPO and AGV-XPO). The drive and scan head motors are then adjusted so that all movements take place within defined quality criteria. This allows the performance of the laser scanning systems to be maximised with minimal set-up effort.

The DrillOptimiser is available both as a stand-alone user interface in Automation1 Studio and as a .NET DLL. This enables seamless integration into the HMI (Human Machine Interface) of the respective machine control system.

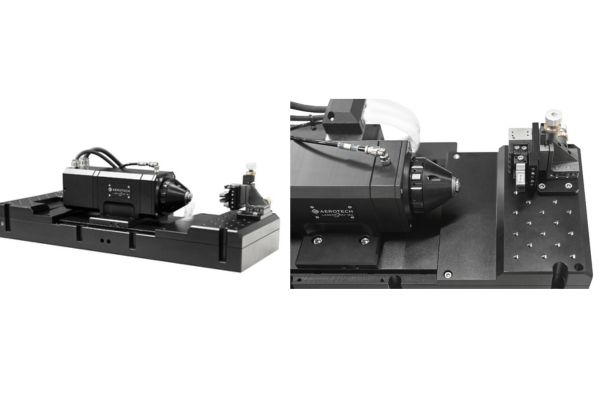

LaserTurn 160: Optimised rotation and linear movement

The second generation of the LaserTurn 160 platform will also be presented at the stand – a powerful solution for the high-precision machining of cylindrical workpieces, particularly used in medical device manufacturing. The system combines directly driven linear and rotary axis with optimised material handling and enables, among other things, laser wet cutting. In addition to the proven CCS130 configuration, an optional cable management system (CMS) is now available to simplify handling. The new ASR1300 rotation upgrade also increases throughput and expands the processing capacity for workpieces up to 4 mm in diameter.

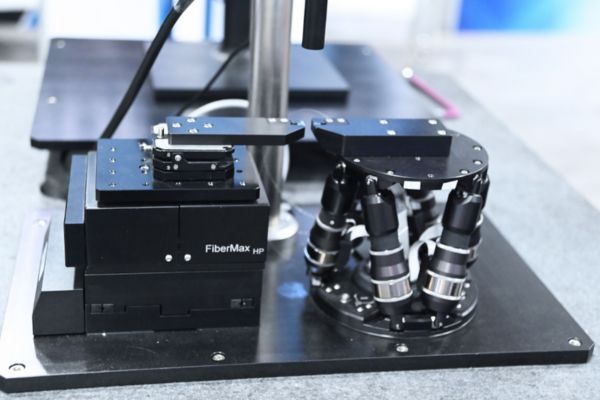

FiberMax: Nanopositioning at the highest level

The FiberMax 3-axis system with ANT stages (XYZ) and a HEX150-140HL enables precise nanopositioning for photonics applications. At the trade fair, a live demo will show how the system uses special routines to achieve fibre alignment with maximum accuracy. While the ANT stages take over the arrangement of the fibres, the HEX150-

140HL takes care of the angular alignment and the blind move function – i.e. the ability to return exactly to the original position after a long movement.

The high-precision mechanics are coupled with the Automation1 control platform, which enables low-latency motion control and optical alignment algorithms. This allows all automation processes to be programmed via a central control interface.

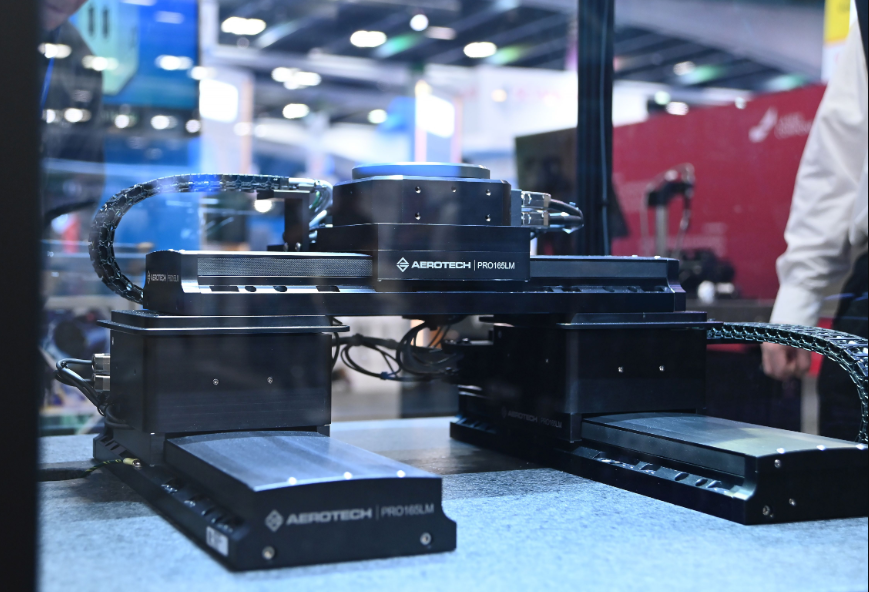

Gantry demo: Dynamic portal control with high flexibility

Aerotech is also presenting a high-performance gantry system that has been specially developed for highly dynamic motion sequences. The design is based on PRO-LM tables, supplemented by an ADRS drive on the bridge. FLEX cable management improves cable routing, while swivel joints between the uprights and the bridge enable easy rotation around the vertical axis. The demo impressively illustrates the possibilities of gantry control – especially with the aggressive high-speed movements that make the system a real eye-catcher at the trade fair.

Automation1 2.10: New functions for maximum control

The latest release 2.10 of the Automation1 motion control platform offers enhanced control functions for greater precision and safety. The new features include ● Dynamic plot display with conditional signal colour and visibility adjustment ● Improved access control and secure communication for drive controls ● 20 kHz laser control for high-resolution servo axes

● Advanced galvo calibration for more precise marking and measurement ● Optimised fine-tuning with current loop feedforward for higher bandwidth ● Further improvements: Updated documentation, PWM optimisation, API enhancements (.NET & Linux)

IGM positioning systems: More rigidity and dynamics

Last but not least, Aerotech is presenting a powerful IGM positioning system that, in combination with an AGV-20HP laser scanning head, increases scanning speed and improves throughput. The IFOV (Infinite Field of View) function synchronises servo axes and laser scanners to reduce errors and stitching effects and increase machining accuracy.

“By combining granite with specifically selected bearing types, our IGM positioning tables enable a particularly rigid design,” explains Simon Smith. “This design ensures maximum stability and precision and can be flexibly adapted to individual customer requirements.”