The battery management system (BMS) is one of the most vital components of an electric vehicle (EV), ensuring safe and efficient management of the battery pack and thereby influencing the safety, range and performance of EVs. Traditional BMS are wired systems which limit the design flexibility and EV production scalability, as well as increase the weight of the vehicle. A more advanced approach is to perform the communication between the Cell Monitoring Controller (CMC) for each battery module and Battery Management Controller (BMC) wirelessly. This simplifies the assembly, maintenance, and exchange of cells resulting in cost and effort advantages. In addition, it saves space and provides weight reduction in the vehicle.

ADI, a global semiconductor leader and pioneer for battery management technology, has developed a complete wBMS. ADI’s wBMS, currently in production across multiple EV platforms, is the first ISO21434 CAL4 compliant wBMS which adheres to the strictest cybersecurity standards. It also meets high requirements in RF performance and robustness to maximize battery capacity and lifetime value.

Ultra-compact automated test system for production lines

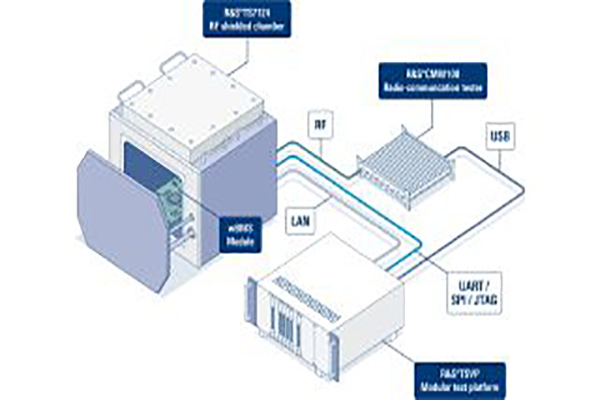

Rohde & Schwarz, together with ADI, has developed an ultra-compact automated test equipment (ATE) system for wBMS. With this test setup, the necessary wBMS module calibration, receiver, transmitter and DC tests can be conducted fast and executed reliably for verification in the lab as well as for production tests for high yield. It consists of the R&S CMW100 radio communication tester, the R&S WMT wireless automated testing software framework, and the new R&S ExpressTSVP universal test and measurement platform. Due to radiated test, the device under test (DUT) is placed in an interference-free environment such as the R&S TS7124 RF shielded box.

Record and playback solution for RF robustness testing of wireless BMS

For RF robustness testing, Rohde & Schwarz and ADI worked together to get an off-the-air recording solution to capture real-world RF spectrum. They then played it back in the lab to confirm the correct operation of wBMS in demanding RF environments. This solution from Rohde & Schwarz allows a realistic, repeatable, and efficient verification of wireless devices. During several test drives in various complex RF environments, an R&S FSW signal and spectrum analyzer monitored the RF spectrum and sent it to an R&S IQW wideband I/Q data recorder. For playing back the recorded spectrum profiles in a lab, the R&S IQW is connected with an R&S SMW200A vector signal generator.

From the development lab to the production line, Rohde & Schwarz offers a comprehensive portfolio of test solutions for wBMS.

Juergen Meyer, Vice President Market Segment Automotive at Rohde & Schwarz says: “We apply our market-leading technical expertise to develop innovative solutions through the entire lifecycle from pre-development to production. We are glad that we are working with ADI to mitigate wBMS test challenges from R&D to mass production, maximize the robustness and performance of wBMS and help enable the automotive industry to fulfil the potential offered by wBMS.”

Rohde & Schwarz will present its wBMS solution at the CES 2024 trade show in Las Vegas from January 9 to 12, 2024 at booth 6567 in the West Hall.