Seica was pleased to announce at SMT 2023 in Nuremberg the latest, leading-edge, completely automated test solutions.

Automation is now pervasive in today’s factories and in most production lines, and the solutions on display are all ready for deployment in completely automated lines.

The fully automated COMPACT SL NEXT> has been designed for maximize configurability and customization, to satisfy the full range of test requirements: from in-circuit, to functional, to combinational, as well as performing other tasks such as onboard programming (OBP). As part of Seica’s COMPACT line of test solutions, the COMPACT SL allows the user to choose the most suitable configuration for today’s need, while ensuring scalability for future requirements.

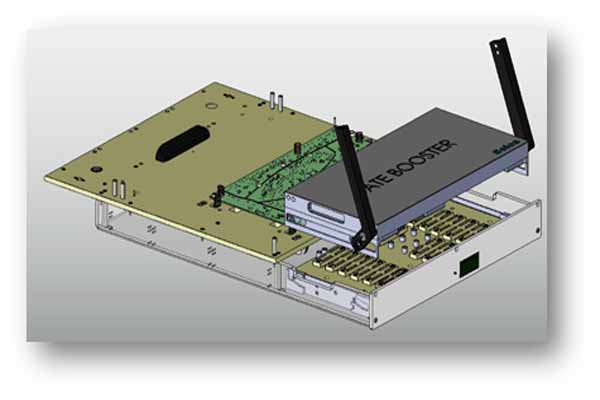

The new ATE BOOSTER module, made its premiere showing at SMT 2023, is the latest addition to the vast suite of performances available for Seica’s COMPACT line. The ATE BOOSTER is designed to maximize LED test capability and OBP performances, while reducing costs by means of innovative optimization of the hardware resources required.

ATE-BOOSTER – THE REQUEST

Companies that have a bed of nails system and need to test a lot of leds on a single board, find the problem to pay a lot of money for create a fixture with all Led sensors needed (one sensor per led).

For example, a fixture with 132 led sensors could cost more than 10 k$.

Same for applications that need to program micro that require short cable distance: you need to install one or more programmer directly on the fixture in order to be as much as possible near to the target device.

Moreover, each products needs its dedicated fixture: so if a company have several products with a lot of leds and/or micro, the cost is too high.

THE SOLUTION

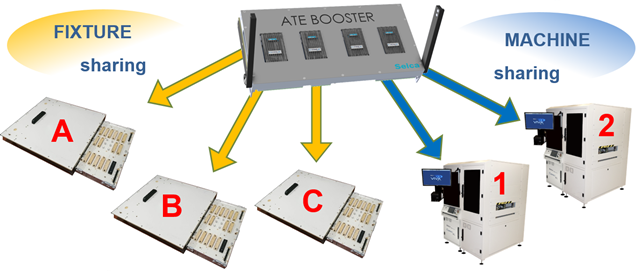

The ATEBooster is the perfect solution to reduce costs with several advantages:

- It’s a part of the system, but is mounted on the fixture! So it’s interchangeble!

- Interchangeable means that you have more room in the fixture for additional devices!

- Backwards compatible!

- Up to 16 Led sensors with hardware integrated that allow to do up to 320 parallel Led test!

- Reliable: optic fibers are not moved or touched during setup

Stable measurement: only one optical transition directly on the sensor

- Up to 4 DeviceClip installed directly on the AteBooster to reach up to 16 true parallel OBP!

- Fast communication speed: since the AteBooster is placed close to the target device, also the DevClip are placed near the UUT, so the communication speed is dramatically increased!

So, thanks to this solution is possible to remove expensive devices from the fixture and share on different projects, with a final result of an incredible cost effective.

1 Ateboost (bought once)à Infinite different applications (can be shared between machines)

INGENIOUS BUT SIMPLE

Inside the ATEBOOSTER there is space for other resources, like:

- JTAG controller

- CAN/LIN controller

- Other…

COMPATIBLE WITH:

Motorized press

Pneumatic press (under development)