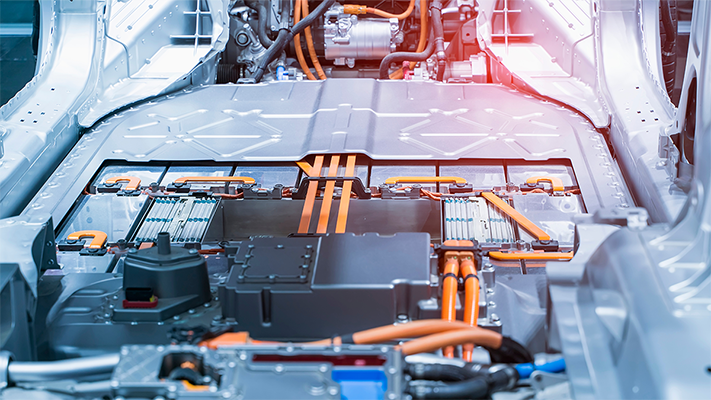

In today’s electronics applications, batteries power nearly all our portable electronic devices. Batteries also serve as emergency power backup systems on large premises. Plus, all-electric vehicles use large cascading battery packs to meet the expected power for the required performance.

Battery packs need the required specific power (W/kg) to be able to dispense enough current to achieve the electric vehicle speed performance. They also need the required specific energy (Wh/kg) to achieve longer runtime or travel range.

Why is it important to monitor battery temperature?

Most rechargeable batteries today use lithium ion and have an operating range between 15 °C and 35 °C at which their full performance and capacity kick in.

- If the battery operates at an ambient temperature below 15 °C, you may experience sluggish electrochemical reactions within the battery and as a result, lower battery performance and reduced charge capacity.

- If the battery or battery pack operates above 35 °C in ambient temperature, battery degradation can accelerate over time. As a result, you may notice shorter battery life, non-uniform aging due to thermal gradients, greater exposure to safety issues, and higher life cycle costs. At extremely hot temperatures, batteries can break down and cause leakage, smoke, fire, and even explosions.

The power map chart below shows the power limits of lithium-ion battery cell, module, or packs across the temperature range. The range between 15 °C and 35 °C is the optimum operating temperature range for the batteries to achieve full performance. This temperature range is also the most efficient, reliable, and safe range for battery operation.

When to use a data acquisition (DAQ) system for monitoring battery temperature

A data acquisition (DAQ) system is one of the most versatile instruments to measure the temperature of an individual object or multiple objects. A DAQ system monitors temperature at multiple points in a product’s battery system. Typically, you initially test functional design blocks independently, and then you test sub-integrated design blocks during a product design and development stage. Testing for lab battery packs and systems occurs during an early product design cycle using several common R&D lab instruments.

A DAQ system can be used to: monitor temperature at multiple points in a product’s battery system, charge the battery system with a DC power supply, and use a DC electronic load to discharge the battery system. Figure 2 below shows a common lab setup using a DAQ system. If you happen to own a bidirectional DC power supply that can source and sink current, then you can replace the separate DC power supply and DC electronic load with a bidirectional DC power supply.

Figure 3 below shows an example of PC-based data acquisition software that complements the DAQ hardware to improve productivity. Using such a data acquisition software application, you can quickly set up and execute tests and get results faster. Some PC data application software allows you to graphically build automated tests, and reduces test development time significantly. The software basically enables graphically intuitive instrument settings, sequencing of measurements, and interacts with multiple instruments to help you create your own complete automated test.

The example in Figure 3 shows a PC-based data acquisition software that allows you to:

- Test the battery management system in your devices by varying the charging sources and discharging the electronic load, while monitoring the temperature and behaviour of your battery system.

- Perform multiple temperature point measurements to evaluate cell-to-cell temperature variations.

- Set alarm triggers to monitor temperature, voltages, or currents if they go above or below acceptable limits.

When to use a specialized battery test system for monitoring battery temperature

Performing quick workarounds on bench test instruments may serve you well for quick troubleshooting and verifying your battery system design. However, when you need to run comprehensive and reliable battery tests that meet standards compliance and conformance tests, use a specialized battery test system that comes with a dedicated centrally controlled battery test software.

A dedicated and well-supported specialized battery test system is needed to provide reliable and precise testing of battery systems, whether they are in the cell, module, or at the pack level. A good battery test system can run customized performance, function, aging, and environmental tests.

The battery pack test system, as shown in Figure 4, for example, is scalable up to 1000 V, ± 2400 A, and ± 360 kW. Scalability is a very important factor for protecting your test hardware investments. The battery test system must also be flexible and suitable for various energy storage applications such as automobile transportation to industrial and other large on premise use cases.

A good battery test system comes with integrated test environments for your device under test (DUT), such as temperature and climate chambers, conditioning for your DUT, and standardized contacting systems for easy integration to your DUT. It is also important to have built-in safety and security mechanisms to help you avoid potentially hazardous situations.

A central battery test system software is also essential to control individual or multiple fully integrated battery test systems for cells, modules, and packs. A good web-based central battery test system software will also be able to:

- Control and monitor all components in the test environment

- Customize test procedures with the availability of predefined standard tests

- Execute test measurements with data recording complete with time stamp for synchronous analysis

- Provide power visualization of measurement data

Ultimately, the central battery test system software should permit validation tests that meet all standard-compliant tests (for example, International Organization for Standardization (ISO), Deutsches Institut für Normung European Standards (DIN EN), and the Society of Automotive Engineers (SAE).