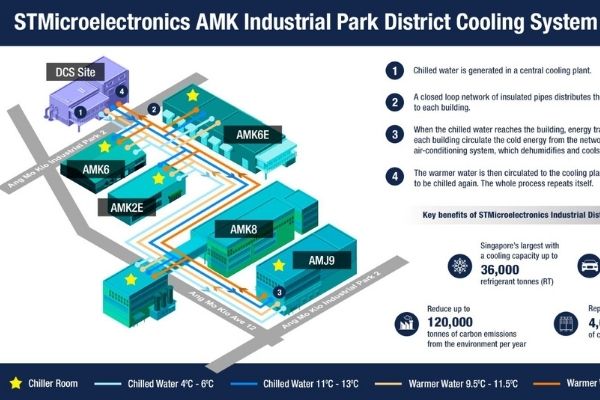

STMicroelectronics and SP Group announced today the signing of and agreement to install a district cooling system at ST AMK Technopark. AT an estimated project value of 370 million USD over 20 years, it will be Singapore’s largest district colling system (DCS) to be implemented for an industrial develpment when operational in 2025.

Under the agreement, SP will design, build, own and operate the DCS, providing chilled-water-as-a-service to meet both the manufacturing and spatial cooling needs of ST. With a cooling capacity of up to 36,000 refrigerant tons (RT), it will help ST achieve 20 per cent savings in cooling-related electricity consumption annually by improving aggregated chiller system efficiency, as well as enable ST to reduce carbon emissions of up to 120,000 tons per year for ST Technopark, equivalent to taking 109,090 cars off the road. This decarbonization is a result of lower energy consumption and an increased capacity to incorporate solar energy and Perfluorocarbons (PFC) abatement equipment by repurposing more than 4,000 square meters (sqm) of chiller plant space that will be freed up once the DCS is operational.

Ms Low Yen Ling, Minister of State, Ministry of Culture, Community and Youth & Ministry of Trade and Industry, attended the event as guest-of-honor to bear witness to the signing of the agreement.

She said: “The private sector plays an important role, alongside the public and the people sector, in advancing Singapore’s climate and sustainability goals. Businesses that adopt sustainable practices, such as energy efficiency improvements, send strong signals to their partners and customers about the urgency of sustainability issues and the need for serious action. At the same time, businesses can harness sustainability as a competitive advantage.”

She further added: “I hope this initiative will inspire many more innovative decarbonization solutions across other industrial developments and spur more companies to seek opportunities in sustainability.”

The cooling system will be ST’s first deployment of district cooling at a manufacturing facility globally. ST is committed to a global target to become carbon neutral by 2027. Adopting district cooling at its single largest wafer-fabrication site (by volume) will be a key enabler for the facility to meet the Minimum Energy Efficiency Standards (MEES) set by the National Environment Agency (NEA), and for the company to achieve its sustainability goals.

“The cooling system in Singapore will be ST’s first deployment of district cooling at a manufacturing facility globally and is a strong statement of our commitment to our target to become carbon neutral globally by 2027,” said Rajita D’Souza, President of Human Resources and Corporate Social Responsibility at STMicroelectronics. “Our adoption of district cooling at our single largest wafer-fabrication site (by volume), where it will eliminate 120,000 tons of carbon from the environment, equivalent to 30% of ST Singapore’s carbon emission in 2021, is a key enabler for the facility and the company to achieve its sustainability goals.”

Group Chief Executive Officer of SP, Stanley Huang, said, “District Cooling is a key sustainable energy solution to empower a low-carbon future for cities, townships, and industrial parks. To enable the decarbonization of Singapore’s industrial sector, we have customized this solution to help energy-intensive manufacturing developments such as STMicroelectronics’ TechnoPark reduce their energy consumption and carbon footprint in line with their sustainability strategies. With our full suite of sustainable energy solutions including solar and electric vehicle charging, we look forward to collaborating with ST to meet its net-zero targets.”