In an exclusive interview with TimesTech, Vinay Kumar Thapliyal from STMicroelectronics reveals the company’s product development roadmap, highlighting the integration of FD-SOI and PCM technologies in their next-generation STM32 microcontrollers. With a focus on security, connectivity, and edge AI, ST aims to empower developers in industrial applications with innovative solutions.

Read the full interview here:

TimesTech: What is ST’s product development roadmap?

Mr Vinay: As a leading innovator in the semiconductor industry, ST has pioneered and brought to our customers FD-SOI and PCM technologies for automotive and aerospace applications. We are now taking the next step to bring the benefits of these technologies to developers of industrial applications starting with our next-generation STM32 microcontrollers. We invest heavily in research and development to incorporate the latest technologies and features. Among the many areas in which we innovate there are three of particular focus: security, connectivity and increasing autonomy enabled by edge AI. This includes building more advanced hardware solutions, integrating software and creating ecosystems that enable developers to go further, faster.

For STM32 portfolio, we focus on five product categories, focusing on

- wireless microcontrollers, STM32WBA5 lines,

- embedded microprocessors with 64-bit STM32MP2 series,

- high-performance microcontroller lines with STM32H7R/S, and

- finally, new entry-level ultra-low power STM32U0.

TimesTech: What’s the additional cost of this FD-SOI 18nm process compared to 40nm, and what motivated the choice of PCM memory here (compared to MRAM, FRAM, RRAM)?

Mr Vinay: The FD-SOI 18nm process brings lots of benefits in terms of capability of integration. What really matters is the die cost and the product cost that we will be enabled to add and offer to our customers.

What we are proposing with this device is competitive and it brings advantages with the same integration capability compared to other 40nm MCUs or other MCU technology. The PCM choice was motivated by the density of memory integration, the capability of having a very small memory cell with high reliability. This has already been validated with our automotive customers in different products in the 28nm node, and our experience reassures us of the capability of integration and the reliability of the PCM compared to other technologies.

The whole concept of PCM is its ability to change from crystalline to amorphous state. To do that, we only need a monodirectional selector, often a BJT. Such an approach allows the PCM to be very efficient in terms of density, but also in terms of reliability. For STM32 products we often talk about operating temperatures between – 40 and +140 degrees celsius, code memory reliability in decade at a given temperature, and data memory which is reliability counting in years at a certain temperature. This means the mission profile is very challenging, and PCM provides not only super optimized density but also reliability.

As to FD-SOI, it provides great electrostatic behavior and records low mismatch properties, all of that translates into very low power designs and products. Back biasing allows us to find the real sweet spot between a certain frequency range and the voltage required. The combination of FD-SOI and PCM was never made available in this type of sub-20nm geometry and class of products.

One more fundamental thing is the ability to support natively 3.3 Volt gates. It is fundamental for us in the industrial market because this class of voltage is very congruent with the performance of high precision analog I/Os. Supporting that makes a big difference natively because for power supply, reliability often becomes a concern when you need to run your I/Os in overdrive mode.

TimesTech: What distinguishes the current applications of MCUs and MPUs in Edge AI? What strategy does ST have for the Arm Ethos series IP in the STM32 MPU product line?

Mr Vinay: MCU are more for entry / mid-level use cases (motion and simple vision), MPU are more for mid / high-level use cases (vision and audio). ST at the moment prefer some proprietary IP for AI acceleration to maximize the synergy between HW and ecosystem that we manage both.

TimesTech: Highlight key features of STM32MP2

Mr Vinay:

- STM32 microprocessors: STM32MP2 series as the second-generation microprocessors enabling secure, advanced edge AI in Industry 4.0.

- 64-bit MPU with advanced compute capabilities, including edge AI acceleration

- Designed for highly connected applications

- Robustness for complex industrial applications

- Built for speed, security, and reliability

- Leverage STM32 ecosystem for rapid development and secure provisioning

TimesTech: What ecosystem STM32MP2 is offering to support Edge AI applications?

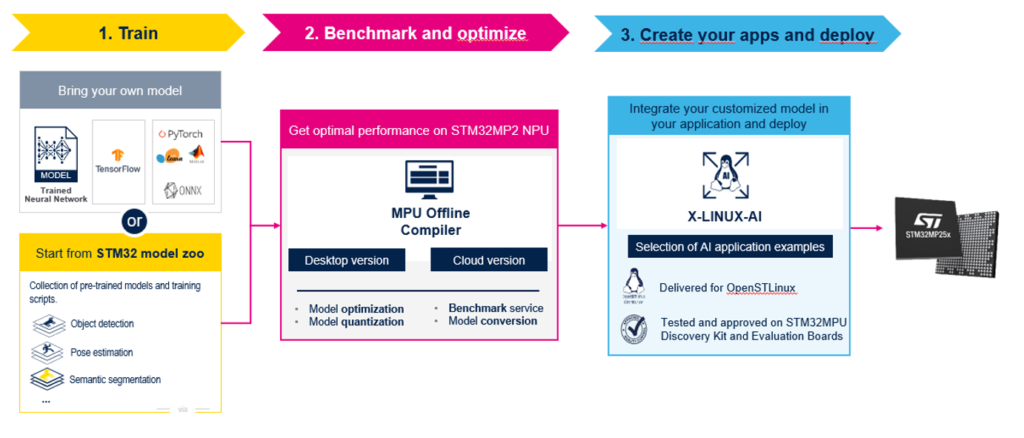

Mr Vinay: Users can seamlessly integrate AI into STM32MP2 based projects. For this, ST offers all 3 key block support – Training, Benchmark & optimize, creating application & deploying.

Below diagram can explain this in better way: