In the era of Industry 4.0, energy efficiency has become a cornerstone of sustainable and cost-effective manufacturing. Energy Measurement Integrated Circuits (ICs) are critical components in achieving this objective. By enabling precise energy monitoring and real-time analytics, these ICs empower manufacturers to optimize processes, reduce waste, and meet stringent energy compliance standards. For industry experts, leveraging energy measurement ICs is key to driving operational efficiency and sustainability in modern manufacturing facilities. According to the Consegic Business Intelligence report, Energy Measurement Ics Market is estimated to reach over USD 9,250.18 Million by 2031 from a value of USD 5,079.61 Million in 2022 and is projected to grow by USD 5,324.75 Million in 2023, growing at a CAGR of 7.1% from 2023 to 2031.

Understanding Energy Measurement ICs :

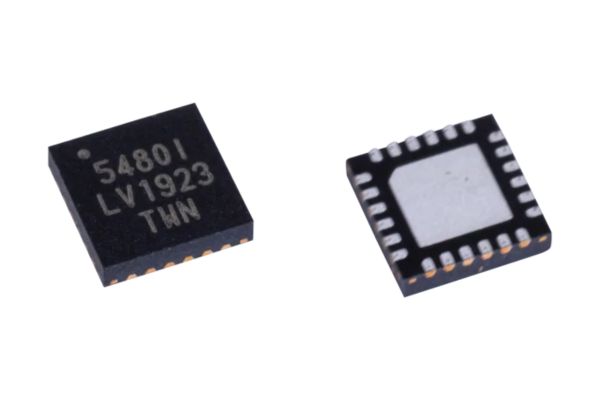

Energy measurement ICs are specialized chips designed to measure, monitor, and analyse energy consumption in industrial systems. These devices provide high-accuracy data on parameters such as voltage, current, power, and energy usage. Key features of these ICs include:

High Precision: Advanced measurement algorithms ensure accurate readings, even under varying load conditions.

Wide Dynamic Range: Support for a broad spectrum of current and voltage levels makes them suitable for diverse industrial applications.

Integrated Communication Interfaces: These ICs often include communication protocols such as SPI, I2C, or UART, enabling seamless integration with IoT systems and factory management platforms.

Enhancing Energy Monitoring in Manufacturing :

Energy measurement ICs serve as the foundation for energy monitoring systems in smart factories. By providing granular visibility into energy usage at the equipment or subsystem level, they enable manufacturers to identify inefficiencies and implement corrective measures.

For example, in a CNC machining center, an energy measurement IC can monitor the power consumption of motors, spindles, and cooling systems. This data helps pinpoint energy-intensive operations, paving the way for targeted process optimizations.

Moreover, real-time monitoring facilitated by these ICs allows for immediate detection of anomalies, such as power surges or equipment malfunctions, reducing downtime and preventing potential damage.

Driving Predictive Maintenance and Operational Efficiency :

Energy measurement ICs are integral to predictive maintenance strategies, which rely on real-time data to anticipate and address equipment failures before they occur. By analysing energy consumption patterns, manufacturers can detect deviations indicative of wear and tear or suboptimal performance.

For instance, an abnormal increase in power consumption in a conveyor motor could signal mechanical issues or misalignment. With insights from energy measurement ICs, maintenance teams can address the issue proactively, avoiding costly unplanned outages.

Additionally, energy consumption data from these ICs can inform operational decisions, such as load balancing and scheduling. By aligning energy-intensive tasks with periods of lower demand, manufacturers can achieve significant cost savings while minimizing environmental impact.

Integration with IoT and Data Analytics :

Energy measurement ICs play a pivotal role in the Industrial Internet of Things (IIoT) ecosystem. By integrating with IoT gateways and cloud platforms, these ICs enable advanced data analytics and visualization.

Using machine learning algorithms, manufacturers can derive actionable insights from energy data, such as identifying patterns linked to equipment performance or optimizing energy use across production lines. Furthermore, integration with energy management systems (EMS) facilitates compliance with energy standards and reporting requirements.

Future Trends and Innovations :

As manufacturing evolves, energy measurement ICs are advancing to meet new challenges. Emerging trends include:

Increased Integration: ICs with built-in microcontrollers and wireless communication capabilities simplify deployment in distributed systems.

Higher Accuracy: Advanced calibration techniques and noise reduction technologies are enhancing measurement precision.

Energy Harvesting: Future ICs may incorporate energy harvesting capabilities, enabling self-powered monitoring solutions in remote or hard-to-access locations.

Source : Energy Measurement ICs Market