As manufacturing processes become increasingly complex, the demand for higher efficiency, reduced latency, and enhanced computational power has grown significantly. Hardware acceleration has emerged as a critical technology in optimizing these processes by offloading computationally intensive tasks from general-purpose CPUs to specialized hardware components such as GPUs, FPGAs, and ASICs. This article explores the role of hardware acceleration in manufacturing, its key benefits, and future trends driving its adoption. According to the Consegic Business Intelligence report, Hardware Acceleration Market is estimated to reach over USD 107.48 Billion by 2032 from a value of USD 4.27 Billion in 2024 and is projected to grow by USD 6.32 Billion in 2025, growing at a CAGR of 49.6% from 2025 to 2032.

Enhancing Computational Performance in Manufacturing:

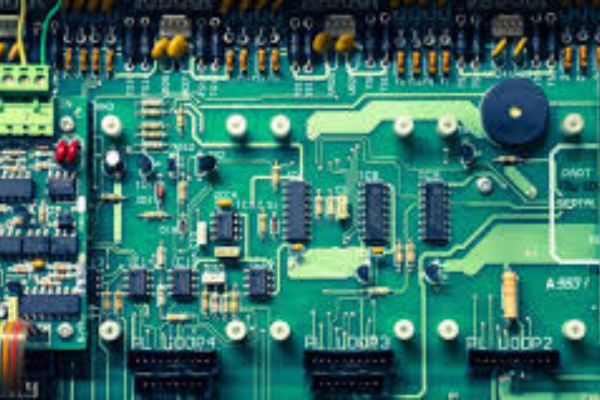

Manufacturing operations require real-time data processing, advanced analytics, and AI-driven automation to ensure precision and efficiency. Hardware accelerators such as graphics processing units (GPUs) and field-programmable gate arrays (FPGAs) enable parallel processing capabilities that significantly improve the performance of computational tasks. These accelerators facilitate faster simulations, predictive maintenance, and complex robotics control, reducing production bottlenecks and improving overall throughput.

Applications of Hardware Acceleration in Manufacturing:

AI and Machine Learning for Predictive Maintenance

Predictive maintenance relies on AI algorithms to analyse sensor data and predict equipment failures before they occur. Hardware accelerators expedite these computations, enabling real-time failure detection and minimizing unplanned downtime. FPGAs and TPUs (Tensor Processing Units) are particularly effective in accelerating machine learning models for predictive maintenance applications.

Computer Vision for Quality Control

Automated quality inspection systems use computer vision to detect defects and ensure product consistency. Hardware acceleration allows image processing and deep learning models to execute rapidly, improving defect detection accuracy and reducing false positives. High-performance GPUs and FPGAs support edge computing capabilities, enabling real-time quality assessments without the need for cloud processing.

Industrial Automation and Robotics

Robotic systems in manufacturing depend on real-time processing for motion planning, object recognition, and environmental awareness. Hardware accelerators improve the computational speed of robotic control systems, allowing for faster decision-making and adaptive learning in dynamic manufacturing environments.

Digital Twins and Simulation

Digital twins create virtual representations of physical manufacturing systems, allowing for process optimization and failure prediction. Simulations require extensive computational resources, and hardware accelerators significantly enhance processing speed, making real-time modelling feasible.

Future Trends in Hardware Acceleration for Manufacturing:

Edge Computing Integration

The adoption of edge computing in manufacturing allows for real-time data processing closer to the production site. Hardware accelerators enable edge AI models to analyse data locally, reducing latency and dependency on cloud infrastructure.

Advancements in FPGA and ASIC Technologies

FPGAs and ASICs are evolving to offer higher efficiency and flexibility in manufacturing applications. Their ability to handle real-time data analytics, AI inference, and signal processing makes them ideal for mission-critical operations.

5G and Industrial IoT (IIoT) Synergy

The combination of 5G networks and IIoT devices will enhance manufacturing connectivity and data exchange. Hardware acceleration will support the rapid processing of high-volume data streams generated by smart sensors and automated systems.

Conclusion:

Hardware acceleration is transforming manufacturing by enabling higher efficiency, real-time processing, and AI-driven automation. As manufacturing facilities continue to embrace advanced computing technologies, the role of hardware accelerators will become increasingly vital in driving cost efficiency, productivity, and innovation. With continuous advancements in edge computing, AI integration, and semiconductor technologies, the future of hardware-accelerated manufacturing looks promising, paving the way for smarter and more efficient production systems.

Source: Hardware Acceleration Market