Digital integrated circuits (ICs) are semiconductor-based chips that incorporate digital circuitry, offering various advantages such as low power consumption, high reliability, compact size, cost-effectiveness, lightweight design, and ease of replacement. According to Consegic Business Intelligence, the Global Digital IC Market reached a value of USD 93.71 Billion in 2022. It is projected to grow to USD 98.79 Billion in 2023, with an expected CAGR of 7.7%, reaching USD 179.47 Billion by 2031.

3D ICs represent a significant advancement in semiconductor technology, as the components are stacked vertically, enabling a higher level of integration and offering improved performance and power efficiency. However, vertical stacking of components gives rise to thermal management challenges that must be addressed for better efficiency and reliability.

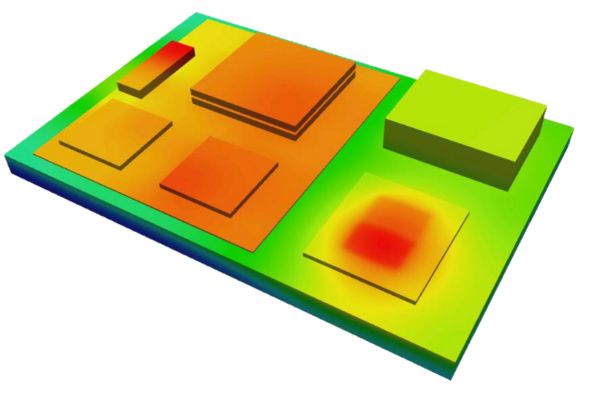

In 3D ICs, vertical stacking significantly increases the power density leading to raised temperatures within the chip as it causes heat to accumulate in the central layers of the stack, making it difficult for heat to dissipate naturally. This creates thermal hotspots that can degrade the performance and reliability of the IC. For instance, modern 3D IC designs may involve stacking up to 100 layers, increasing the heat dissipation challenges.

Moreover, heat generated in one layer can affect the performance of adjacent layers, leading to thermal interference. Managing the heat flow between layers is crucial to prevent the degradation and failure of ICs, and ensure the longevity of the ICs. Also, different materials used in manufacturing the ICs have different thermal coefficients, which causes mechanical stress and leads to the failure of the components.

Thermal Management Techniques

Using high thermal conductivity materials like diamond or graphene facilitates heat transfer away from hotspots. Even thermal interface materials are crucial for enhancing thermal contact between layers. Advanced materials like carbon nanotube-based materials, offer superior thermal conductivity compared to traditional silicon and other materials, improving the overall heat dissipation.

Through-silicon Vias are vertical interconnects that pass through the silicon wafer, providing a path for both electrical signals and heat to pass through. Optimizing the placement and density of vias can significantly improve thermal management by transferring heat from inner levels to heat sinks. Also, integrating microfluid channels within the IC stack allows for liquid cooling, which is highly effective in managing heat. Coolants can be circulated through these channels to absorb and remove heat from critical areas, maintaining optimal temperatures throughout the stack.

Thermal-aware design of the ICs includes the optimization of the layout of the IC to minimize thermal hotspots by strategically placing high-power components and optimizing the distribution of heat-generating elements. Dynamic thermal management dynamically adjusts the operation of the IC based on real-time temperature measurements. This can involve throttling the performance of specific components, distributing workloads to reduce heat generation, and adjusting power delivery to manage temperatures efficiently.

Conclusion

Effective thermal management is crucial for the performance and longevity of ICs. Advanced materials, innovative architectures, and thermal-aware design can address thermal management concerns. As the semiconductor industry continues to push boundaries of integration and performance, ongoing research and development in thermal management will play a pivotal role in the success of 3D ICs.