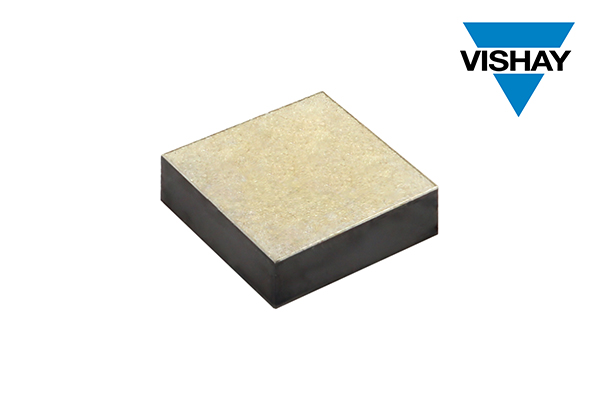

MALVERN, Pa.— Vishay Intertechnology has introduced a new series of leadless NTC thermistor dies — contacted on the top and bottom — that provide designers with versatile mounting options. Vishay BCcomponents NTCC201E4 devices with silver metallization support aluminum wire bonding and are compatible with reflow soldering under vacuum or with formic acid / forming gasses, SAC or SMP soldering, and nano-silver paste sintering.

Operating over a wide temperature range from -55 °C to +175 °C, the AEC-Q200 qualified devices released today are optimized for temperature sensing, control, and compensation in automotive and alternative energy applications. End products will include IGBT and power MOSFET modules and power inverters for electric (EV) and hybrid electric vehicles (HEV), solar panels, and wind turbines.

The top and bottom metallization of NTCC201E4 thermistors feature two layers. An external layer offers superior resistance to soldering leaching compared to previous-generation devices, especially when using high melting point solder materials at temperatures of +360 °C. An internal layer resists board formic acid etching when solder preforms are used and forming H2 / N2 gasses.

RoHS-compliant, halogen-free, and Vishay Green, the thermistors offer resistance at +25 °C (R25) from 4.7 kΩ to 20 kΩ, with tolerance down to ± 1 %, and beta (B25/85) from 3435 K to 3865 K, with tolerance down to ± 1 %. The devices feature maximum power dissipation of 50 mW, response times of 3 s, and are packaged in PS blister tape.

Samples and production quantities of the NTCC201E4 series are available now, with a lead time of 20 weeks.