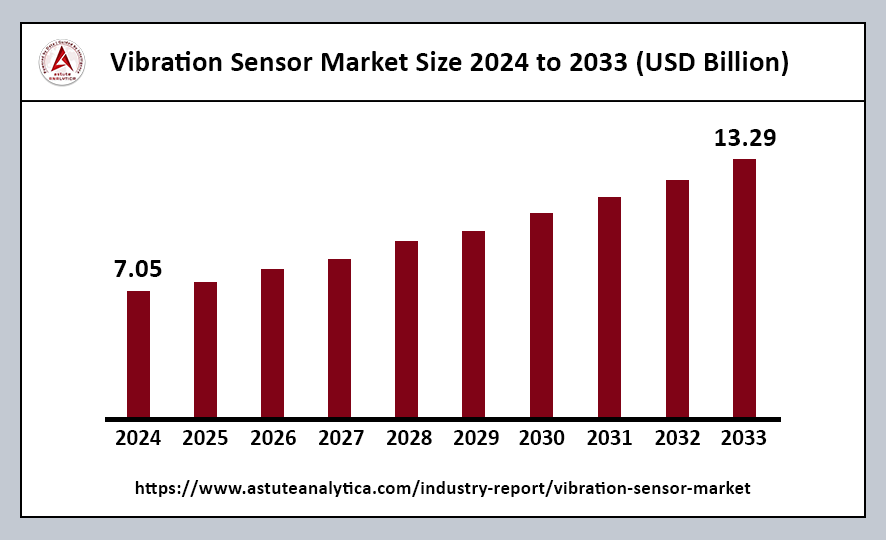

The global vibration sensor market was valued at US$ 7.05 billion in 2024 and is projected to reach US$ 13.29 billion by 2033, reflecting a Compound Annual Growth Rate (CAGR) of 7.3% during the forecast period from 2025 to 2033.

Vibration sensors, especially accelerometers, are becoming increasingly popular due to their affordability, ease of installation, and capability to detect vibrations across a wide frequency range. This versatility is driving growth in various industries, including manufacturing, automotive, and aerospace. With the emergence of Industry 4.0, organizations are placing a greater emphasis on automation and predictive maintenance, which enables them to identify wear and tear in machines and equipment before it leads to failures. This proactive approach is anticipated to significantly boost the adoption of vibration sensors throughout the forecast period.

Vibration Sensor Market Key Takeaways

- Accelerometers have firmly established themselves as the most widely used sensor type in the vibration sensor market, commanding over 45% market share.

- The automotive end-user dominates the vibration sensor market, holding more than 38% market share.

- In terms of material, the quartz-based vibration sensor market holds a significant position, leveraging quartz’s unique piezoelectric properties to capture more than 44% market share.

- When examining technology, piezoresistive sensors have carved out a unique niche in the vibration sensor market, boasting over 55% market share.

Regional Analysis

North America’s Commanding Market Position

North America holds a commanding position in the global vibration sensor market, accounting for over 38% market share. This dominance can be attributed to a robust industrial base and a strong emphasis on advanced technological innovation.

- The United States: A Key Region: Within North America, the United States plays a pivotal role, capturing more than 80% of the region’s revenue in the vibration sensor sector. This remarkable share underscores the significant impact of the U.S. market on the overall landscape. The dominance of the United States is reinforced by extensive investments in research and development and the adoption of modern manufacturing practices.

- Supportive Regulatory Frameworks: The supportive regulatory frameworks in the United States further bolster the vibration sensor market. Policies encouraging innovation and technological advancement create an environment conducive to growth. These regulations not only promote safety and efficiency but also incentivize companies to invest in the latest sensor technologies, ensuring that industries remain competitive on a global scale.

- Integration Across Critical Sectors: In the United States, several critical sectors continuously integrate vibration sensor technology to enhance their operations. Industries such as automotive, aerospace, energy, and manufacturing utilize these sensors to monitor engine health, track structural integrity, and implement predictive maintenance strategies.

Asia Pacific: Rapid Growth on the Horizon

The Asia Pacific region is anticipated to experience the fastest Compound Annual Growth Rate (CAGR) during the forecast period for vibration sensors. This growth trajectory is largely attributed to the increasing level of automation across various industries.

- Impact of Automation on Vibration Sensor Demand: The surge in automation within sectors such as manufacturing, automotive, and aerospace is a key driver behind the growing need for sophisticated vibration sensors. These sensors are crucial for monitoring equipment health, ensuring operational reliability, and minimizing downtime through predictive maintenance.

- Influence of Low Labor Costs: Another significant factor contributing to the growth of the vibration sensor market in the Asia Pacific region is the presence of low labor costs. This economic advantage encourages global manufacturers to expand their production bases in India, China, and South Korea. Consequently, this expansion is expected to drive increased demand for vibration sensors within the regional manufacturing sector.

- Manufacturing Hubs for Consumer Electronics: Countries such as China and Japan are recognized as major manufacturing and assembling hubs for prominent consumer electronics manufacturers, including industry giants like Samsung and Sony Corporation. The concentration of manufacturing activities in these countries not only bolsters local demand for vibration sensors but also positions them as critical players in the global market.

Top Trends Escalating the Vibration Sensor Market

Wireless Sensors for Flexible and Cost-Effective Monitoring: Wireless sensors are transforming monitoring practices across diverse industrial environments by providing flexible and cost-effective solutions. These sensors eliminate the need for extensive wiring, making installation easier and reducing associated costs. Their adaptability allows industries to monitor various parameters without the constraints of traditional wired systems, enhancing operational efficiency.

Shift from Preventive to Predictive Maintenance: The adoption of wireless sensors has facilitated a significant shift from preventive maintenance practices to predictive maintenance strategies across multiple industries. Predictive maintenance leverages real-time data to forecast potential equipment failures before they occur, allowing organizations to perform maintenance only when necessary. This shift not only reduces downtime but also extends the lifespan of machinery and optimizes maintenance costs.

Increased Use of Piezoelectric Technology: Piezoelectric technology has become increasingly popular in vibration measurement applications. This technology is particularly valuable in applications requiring precise monitoring, such as in aerospace, automotive, and industrial machinery, where minute vibrations can indicate significant mechanical issues.

IoT Integration for Enhanced Monitoring: The integration of Internet of Things (IoT) technology is enhancing real-time monitoring and predictive maintenance capabilities within industrial settings. With IoT-connected sensors, data can be collected and transmitted in real time to centralized systems for analysis. This immediate access to data allows for quicker decision-making and proactive responses to potential issues, ultimately improving operational reliability.

Growing Demand for Industrial Automation and Smart Factories: The growing demand for industrial automation and the development of smart factories are driving the adoption of advanced sensors, including wireless and piezoelectric types. As businesses strive to enhance productivity and reduce operational costs, the implementation of automated systems that rely on sophisticated sensor technology becomes essential.

Advancements in Sensor Technology: Ongoing advancements in sensor technology are significantly improving the accuracy and reliability of vibration monitoring systems. Innovations in materials, design, and data processing capabilities are leading to more precise measurements, which are critical for effective monitoring and maintenance strategies. These improvements not only enhance the performance of existing systems but also contribute to safer and more efficient industrial operations.

Vibration Sensor Market Segmentation

By Type

Accelerometers have established themselves as the most widely used sensor type in the vibration sensor market, driven by their versatility and wide-ranging applications. They play a crucial role in automotive safety, aerospace stability, consumer electronics, and manufacturing processes. With the technical capability to monitor vibrations, shocks, and accelerations across a broad frequency range, accelerometers are indispensable for ensuring machinery health, structural integrity, and optimized performance.

By End User

The automotive industry dominates the vibration sensor market by leveraging advanced sensor technology to enhance vehicle performance and safety. Vibration sensors are integral for monitoring critical parameters such as engine conditions, suspension integrity, and cabin vibrations. They play a vital role in safety-critical systems, including engine control, anti-lock braking, and tire pressure monitoring, ensuring the overall reliability and safety of vehicles.

By Material

The quartz-based vibration sensor market holds a significant position by harnessing quartz’s unique piezoelectric properties to convert mechanical stress into precise electrical signals. Quartz sensors provide superior stability, low power consumption, and exceptional measurement accuracy. These characteristics render quartz an ideal material for applications where long-term reliability is of utmost importance.

By Technology

Piezoresistive sensors have carved a unique niche in the vibration sensor market due to their high precision and reliability in detecting mechanical stress. These sensors are critical for applications that require accurate measurements, particularly in the automotive sector, where robust monitoring of engine performance and tire pressure is essential for ensuring overall vehicle safety and performance. Additionally, their straightforward interface circuitry and ease of integration into existing systems make them a preferred choice over other sensor technologies.

Vibration Sensor Market Recent Developments

- Updated Aussie-Made Vibration Sensor by 365mesh: In March 2025, 365mesh launched an updated Aussie-made vibration sensor. This structural monitoring device is designed for construction, mining, and industrial environments where continuous vibration monitoring is critical for infrastructure safety.

- HBK’s New Piezoelectric Sensors for High Temperatures: In February 2025, HBK introduced new piezoelectric sensors capable of operating at ultra-high temperatures. These sensors are engineered to deliver unmatched accuracy in the most demanding high-temperature applications, making them ideal for aerospace and defense, oil and gas, power generation, pulp and paper, and steel rolling.

Top Companies in the Vibration Sensor Market

- Analog Devices Inc.

- Baumer

- Bosch Sensortec GmbH (Robert Bosch GmbH)

- Emerson Electric Corporation

- Hansford Sensors Ltd

- Honeywell International Inc.

- National Instruments Corporation

- NXP Semiconductors NV

- Rockwell Automation Inc.

- SAFRAN

- SKF GmbH

- TE Connectivity Ltd

- Texas Instruments Incorporated

- Other Prominent Players

Market Segmentation Overview:

By Technology

- Piezoresistive Sensors

- Tri-Axial Sensors

By Type

- Accelerometers

- Velocity Sensors

- Displacement Sensors

By Material

- Quartz-based Sensors

- Doped Silicon Sensors

- Piezoelectric Ceramics

By End-use

- Automotive Sector

- Aerospace And Defense

- Consumer Electronics

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Source: https://www.astuteanalytica.com/industry-report/vibration-sensor-market