A common fundamental technology center that establishes technologies required in areas such as product development, provides various digital tools, and offers physical support. What kind of future does the department that includes engineers that utilize digital tools such as AI (artificial intelligence), CAD (3D model design tool), and CAE (simulation tool) imagine for Murata beyond DX promotion? Dai, of the common fundamental technology center, will provide an introduction of concepts and examples that include cyber physical system construction that makes use of AI.

1. Generating a culture and mindset to actively make use of DX

“The main role of the common fundamental technology center is to generate new technologies Murata requires and establish them. We then provide support so that these technologies we have provided to Murata can be used for operations.”

Our speaker Dai, of the common fundamental technology center, has been engaged in DX promotion by providing proper technology through cooperations with various business divisions and R&D departments. He states he feels the issues of DX promotion firsthand since he had provided technical support and helped solve issues across various departments.

Dai: “While the term DX is widely recognized in society, when asked what kind of changes it can bring, it is difficult for us to imagine what we are to do to incorporate it into our operations. On the other hand, while the engineers at the common fundamental technology center excel in the data science field, it is difficult for them to grasp what actual product development and on-site work was like. To solve this issue, it is crucial both parties are to cooperate.”

Therefore, members of the common fundamental technology center makes it their goal to blend into the manufacturing site and support autonomous development support in accordance with the idea that “value in technology is valid only when applied in the manufacturing site.”

Dai: “For example, in the mobility field, AD (automated driving)/ADAS (advanced driver assistance system) has evolved, and function verification can be performed on simulators. It is our role to create and provide algorithms and models to visualize module performances in simulations as well as construct evaluation environments, and train staff to be capable of using them while providing them with a proper environment. Create technology, maintain environments, and train personnel. I believe that considering these 3 factors as a set will make the technology rooted in the manufacturing site.”

Additionally, successful examples are required to disseminate DX.

Dai: “It is important that staff have the proper digital knowledge, but it is crucial to accumulate successful examples, regardless of how small they are. Through DX, jobs have become more efficient, tasks have become easier, and production quality has improved. These kinds of successful examples will lead to developing positive attitudes towards DX. I acknowledge it is our role to foster a culture and mindset to actively use DX by entering manufacturing sites ourselves in order to dynamically disseminate DX throughout the entire company.”

2. Making the development process more efficient through software, CAE, CAD, and AI

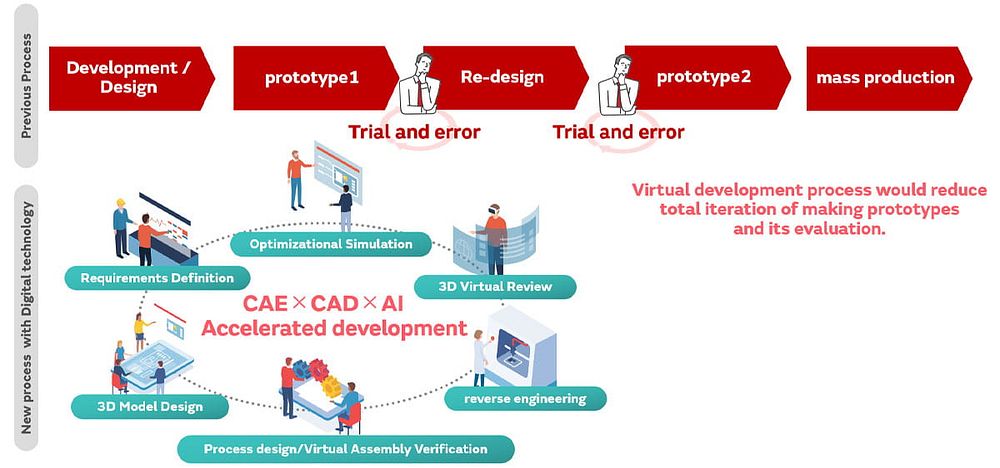

What the common fundamental technology center wishes to achieve in the future is to transfer requirement definitions, prototypes, simulations, and praise of development processes into virtual environments. To construct a cyber physical system that enables development design in virtual spaces regardless of the location.

Dai: “The product and material development process is a repetition of trial and error as well as refinement. Using the digital data of these processes as the core, securing performances in virtual environments using CAD and CAE, and completing prototypes and evaluations in 1 process makes it possible to achieve an innovative task efficiency. Since CAE and CAD use has become fairly common, I would like to boost their level of efficiency by applying AI to them.”

It is believed various effects can be achieved by combining CAE, CAD, and AI.

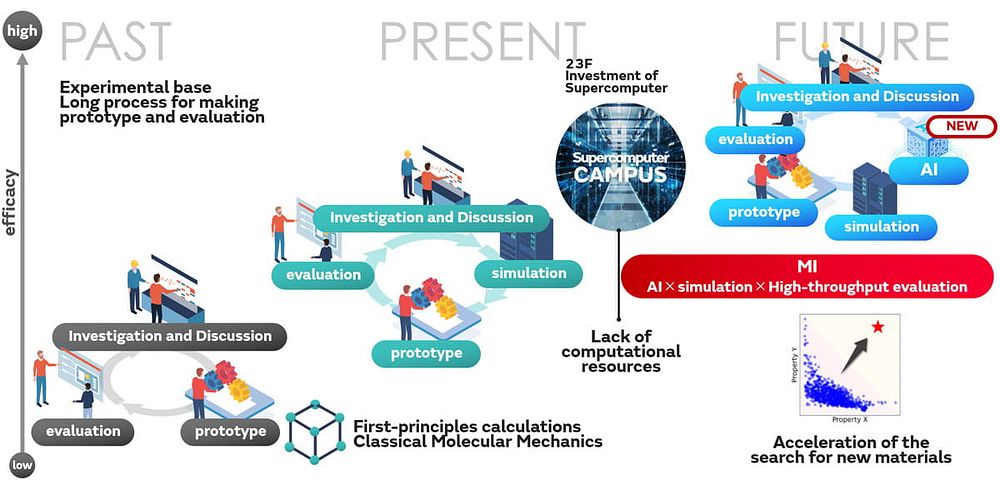

Dai: “Currently, large-scale computing environments are constructed using super computers and are capable of simulation computing by combining a number of parameters. In addition to computing resource reduction, the computing time is shortened by combining AI that has learned evaluation and simulation data. I believe this is what would enable us to achieve goals in minimum time. The precision will increase as AI learning data is accumulated, accelerating the development speed as well.”

Here is an explanation of the effects using the mobility field, where AD/ADAS is evolving, as an example.

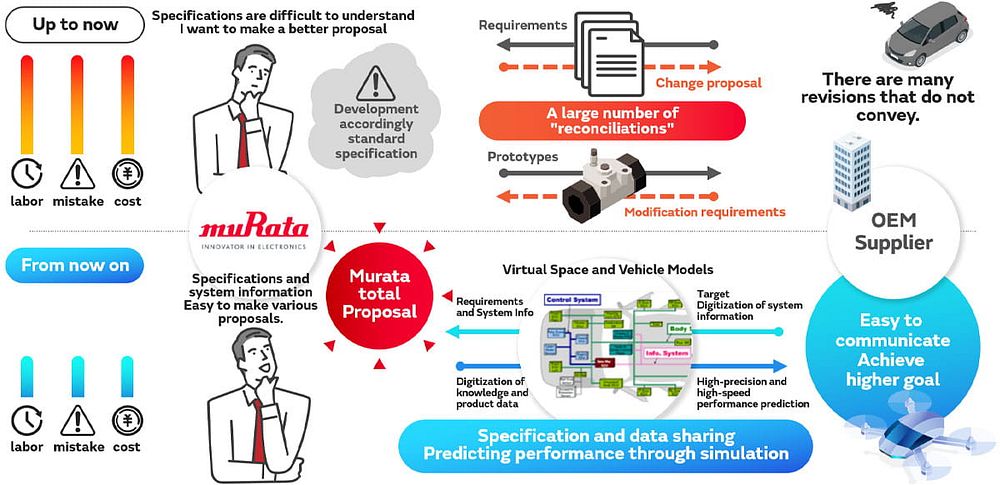

Dai: “There are 2 changes occurring in the mobility field. One change is that performance evaluations for ADAS, etc. are shifting from demonstration experiments to simulation evaluations performed in virtual environments. The other is the necessity to visualize product characteristics for customers based on the changes in market players and propose solutions. Considering these 2 points, we can assume that the effects when software, CAE, CAD, and AI are combined, capable of predicting performance values through simulations using AI, algorithms, and system designs, will become crucial.”

3. Large-scale innovation is required to maintain corporate value

Dai states that one of the major reasons Murata is promoting cyber physical system construction as well as the use of software, CAE, CAD, and AI is because our society is changing.

Dai: “Due to the COVID-19 pandemic, we saw an increase in customers that were in search for online simulation models for parts used in products and were willing to apply them by determining their performances through simulations. Since conventional sales activities and face-to-face discussions were no longer held, there was a risk we could not get our customers to consider our proposals unless we could prepare parts models that could be applied to customer simulations. Therefore, Murata has been providing parts models including modules and MLCCs (multilayer ceramic capacitors) for customer simulators.”

Additionally, Dai mentioned that Murata has already achieved certain results for parts model development in the mobility field.

Dai: “We embedded our models in car simulators and visualized automatic parking on mobility through simulations. Through this, we were able to show how Murata’s ultrasonic sensors would enable parking with a minimum amount of turns. These activities have been effective in having our customers understand the superiority and potential of Murata products.”

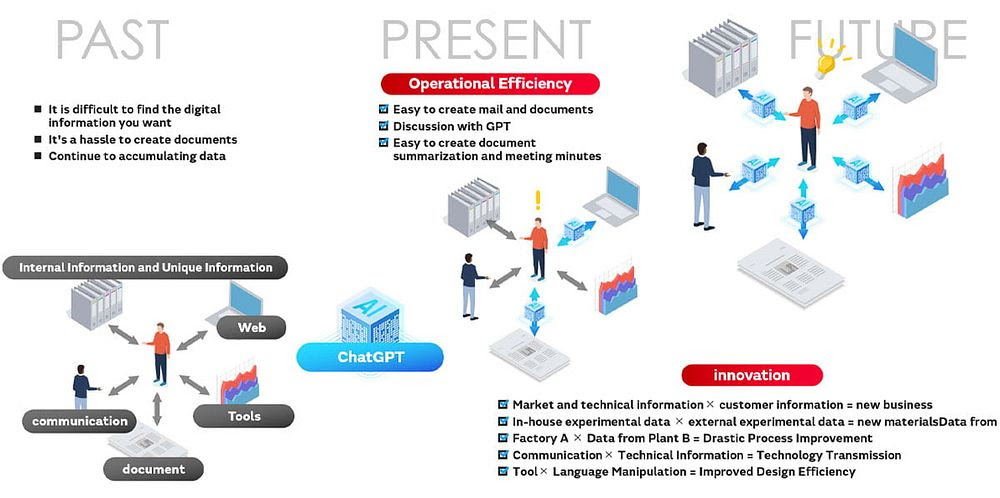

Dai also stated that following the introduction of ChatGPT, Murata must not fall behind in data science usage as well as generative AI which is gaining worldwide recognition.

Dai: “Conventionally, to prove the effects of patents during patent application, it was common to provide experimental data. However, in the United States, there have been several cases patents had been applied for by showcasing the effects through simulation data. Therefore, if we can showcase the effects through simulations, we will be capable of acquiring patents without prototype tests. This is extremely significant for Murata. How will we respond to these social changes while making use of our accumulated technologies and knowhow? I believe we are required to make innovation happen by reviewing our entire development process to maintain Murata’s corporate value and competitiveness.”

Additionally, Dai states, “Generative AI can be applied for familiar tasks such as document creation and idea generation. It is an optimal tool to disseminate DX to people who are unfamiliar with digital processes.”

Dai: “Generative AI can act as a partner for discussions and provide us with opportunities to create new ideas by outputting an enormous amount of information. In the future, it may become a trigger to create innovation that would lead to new businesses and technology transfer. In the development process, the chances new materials are discovered will rise drastically since material exploration ranges will broaden with the help of AI.”

4. More focus on creative tasks as a result of digital process use

As generative AI is disseminated into society and Murata continues to apply it into its operations, Dai analyzes that changes are occurring in human roles and value.

Dai: “Generative AI is learning various things from around the world, but it is still immature in terms of ethics and will not necessarily provide us with correct answers. Digital tools are merely tools. Human beings are the ones to make value judgments. Therefore, we must continue to cultivate ethical as well as specialized knowledge and skills. Instead of generative AI, which continues to learn data from the past, I believe it is us humans who will continue creating new ideas for our future while facing the rapid changes in our society.”

Dai concludes that human creativity is a key factor of DX promotion.

Dai: “Cyber physical system construction aimed to make development processes more efficient are activities introduced to enable human beings to concentrate on creative tasks. DX will become a great tool for innovation and it is without a doubt that creativity is crucial for Murata to make the next leap forward.”