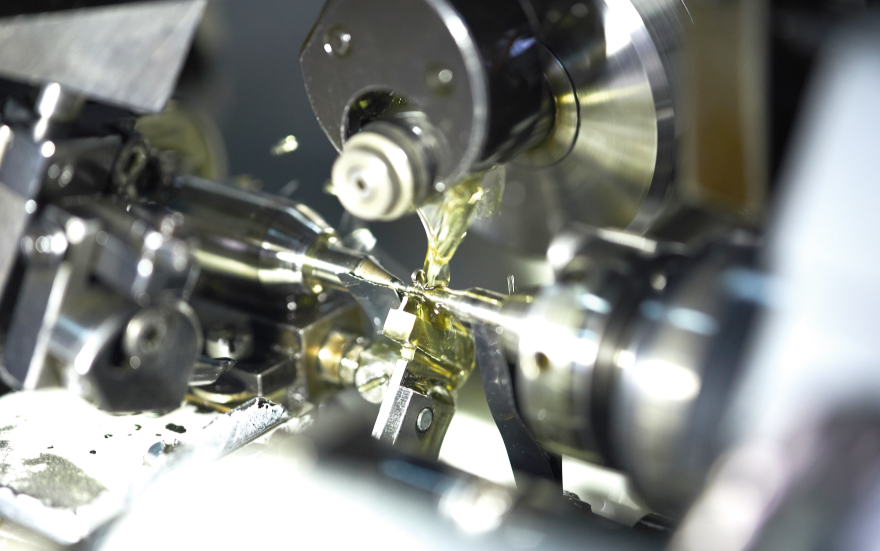

Lubricant specialist Zeller+Gmelin is expanding its portfolio with the metalworking oil Multicut SE 13. This multifunctional machining oil is suitable for a wide range of machining and grinding processes – from turning and milling to demanding applications such as broaching and deep-hole drilling. With high thermal stability, low evaporation, and minimal smoke generation, Multicut SE 13 is a proven performer in both conventional gearbox manufacturing and e-mobility components.

Multicut SE 13 is suitable for a wide range of metalworking processes – including turning, milling, drilling, grinding, honing, broaching, and deep-hole drilling. Even under highly variable machining conditions, such as in automated production lines or with complex component geometries, its lubrication performance remains stable. The combination of high-quality hydrocracked base oils, synthetic greases, and coordinated EP additives ensures reliable performance even under high thermal and mechanical loads.

“During development, our focus was on a cutting oil that is both versatile and process-stable – even under extreme conditions,” explains Dr. Irene Kreitmeir, product manager at Zeller+Gmelin. “At the same time, our goal was to minimise oil mist and smoke generation to reduce stress for machine operators and improve workplace quality.”

Stable lubricating film under high temperature loads

A key feature of the new lubricant is its thermal resistance: The viscosity changes comparatively little upon significant heating, ensuring consistent lubrication even at intense machining temperatures. The oil exhibits a very low Noack evaporation loss, which not only reflects the high lubricant quality but also significantly reduces lubricant consumption. Foam formation is also very low, ensuring maximum process reliability, especially in automated processes.

Multicut SE 13 is also designed for a clean working environment. The formulation minimises the formation of smoke and oil mist, thereby reducing stress for machine operators and achieving better air quality in production.

Sustainability and approvals for demanding applications

The new Multicut lubricant is formulated in accordance with REACH regulations and contains no harmful ingredients. The combination of a sustainable formulation and high technical performance meets both technical and regulatory requirements for modern manufacturing processes.

Biocompatibility according to DIN EN ISO 10993-5:2009 also underscores the high level of responsibility for people and the environment, even in the development of lubricants. Furthermore, it is approved for use in Junker grinding machines – an indicator of its suitability for demanding grinding processes, such as those found in gear or drive technology.

Can be used from classic transmissions to e-mobility

The multifunctional oil combines high technical performance with a sustainable formulation and maximum process versatility. The non-water-miscible cutting fluid is suitable for machining a wide range of materials – including cast iron, steel, stainless steel, and selected aluminium alloys – and is used in traditional industrial sectors such as gear manufacturing as well as in future-oriented fields such as component production for electric drives.

“Our new Multicut SE 13 is a universal solution for the metalworking industry – developed for maximum process reliability while simultaneously achieving high cost-effectiveness and sustainability,” summarises Dr. Irene Kreitmeir.

((Info box))

SE 13 – The multi-functional metalworking oil

Highlights:

. From grinding to heavy-duty machining

. High process reliability at extreme temperatures

. Minimal oil mist, low evaporation loss

. REACH-compliant, free of critical ingredients

. Viscosity: 13.5 mm²/s

Suitable for:

Cast iron, steel, stainless steel, some aluminium

– Turning, milling, drilling, grinding, and much more.

Typical applications:

Gearbox parts and components for electric drives