Driven by concerns about petrol prices, government environmental initiatives, plus large-scale public and private investment in the supporting charging infrastructure, the electric vehicle (EV) sector is undergoing a period a substantial growth. Over the course of the next decade, the automotive market is set to transition from one formerly dominated by internal combustion engine (ICE) vehicles to one where EVs make up the majority of new vehicle sales. As the following article will explain, the higher voltage levels that EV powertrains need to support (compared to their EV counterparts) will have major implications when it comes to specifying constituent passive components.

For the first time, worldwide EV annual sales surpassed 6 million units in 2021. Predictions made by the International Energy Agency (IEA) [1] suggest that this is just the beginning though. It forecasts that sales will have reached 15 million by 2025 and 25 million by 2030.

ICE vehicles have relied on 12V/24V powertrain architectures, with hybrids often being based on 48V systems. EVs, however, have powertrains that are placed at far higher values. Furthermore, in order to accelerate charge times and increase conversion efficiencies, these are being pushed still higher. The new EV models that are just starting to appear on the market have 800V powertrain voltage ratings.

For 48V hybrid systems, the motors will be located on the powertrain itself. This does, however, mean that the accompanying electronics will be exposed to more intense vibrations and thermal cycling. Automotive engineers must look at the effects this will have on component reliability.

Redefining powertrain implementation

The adoption of high voltage levels and location away from the protection of the engine compartment will have implications for the DC-Link capacitors incorporated into EV and hybrid powertrains. Situated between the battery and the traction inverter, these passive components are used to smooth out the voltage and prevent unwanted transient spikes occurring. If they are to be effective, then high degrees of robustness are needed. This will allow them to cope with the challenging application environment that automotive deployment represents. Among the attributes that these capacitors will need to exhibit are an extensive operational temperature range and resilience to ongoing vibrations.

There are other considerations that engineers must be aware of too though. The densely packed nature of automotive implementation means that space constraints need to be respected. Consequently, capacitor solutions should be sourced that have small physical dimensions. Likewise, vehicle manufacturers must keep the overall bill-of-materials expense as low as possible, so the chosen capacitors have to be cost effective.

Vibration and thermal cycling related issues

A key performance parameter for any DC-Link capacitor will be its equivalent series resistance (ESR) value. The lower that its ESR is, the greater its ability will be to smooth out high frequency voltage disturbances passing through the powertrain. If the ESR values that these capacitors present within the electrical circuitry increases due to some form of damage, then the whole powertrain operation could potentially be jeopardized.

Standard multi-layer ceramic capacitors (MLCCs) are not well suited to automotive usage, as they are not able to cope with the acute mechanical stresses involved. If the PCB on which they are mounted flexes, due to either vibration or thermal cycling, then the solder joints will be placed under considerable strain. This can lead to cracks appearing within the ceramic substrate. These cracks can result in moisture ingress arising which will, in turn, impact on the capacitor performance. If these components are located close to the edge of the PCB, then the stresses that they are subjected to are likely to be even greater.

Selecting capacitors with vibration-resilient properties

The vibrations witnessed in an automobile can come from a variety of different sources and be at a wide range of different frequencies. Though these issues are intrinsic in automobile design, they can be mitigated in a number of different prospective ways. These are as follows:

- Specify polymer capacitors instead of MLCCs. These components will have lower ESR values than MLCCs, with better performance across a wide range of operating conditions. There are increased costs involved however.

- Hybrid capacitors might also be applicable. These will be comprised of an anode with a liquid and conductive polymer construction, alongside a cathode made from aluminum. The large surface area of the liquid enables elevated capacitance values to be achieved in a compact form factor. Like the previous option, this comes with added costs.

- Making enhancements to the methods via which the capacitor body and its terminations are interconnected with one another, so that the vibrational forces experienced are dampened.

The rest of this article will look at the third option. This enables greater mechanical robustness to be attained, while still benefiting from the cost advantages of MLCCs.

Vibration-resilient MLCCs

To address the need for capacitors that are able to resist vibrational forces, KEMET developed its FT-CAP series. These MLCCs have an innovative termination arrangement that helps to lower the strain imparted from the PCB when it is flexed. A conductive silver epoxy layer is included in the termination structure (situated between the base metal and nickel barrier layers). This enables terminal strength to be upheld, but provides the cushioning necessary to prevent any cracks from appearing. The capacitor’s continued performance is thus assured. KEMET FT-CAP MLCCs have DC voltage ratings of up to 250V, with capacitance values from 180pF to 22μF available. They can be supplied in case sizes from 0603 to 2225.

Figure 1: Schematic desribing the construction of a FT-CAP MLCC [Source KEMET]

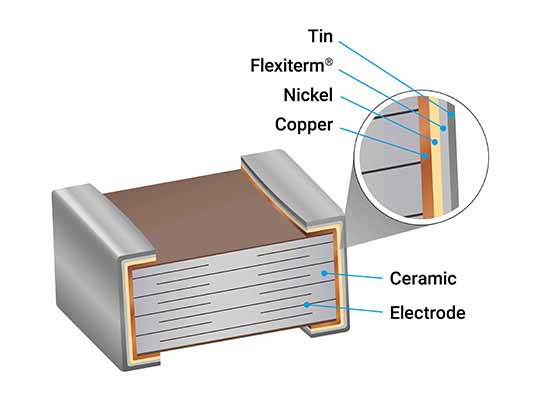

Kyocera AVX is also tackling the vibration issues previously outlined through its FlexitermTM low ESR MLCC products. These also have flexible terminations fitted to them for added elasticity. Here nickel-plated copper terminations are supplemented by a proprietary layer that absorbs incident mechanical stresses. The manufacturer has successfully managed to do this without there being any major increase in the costs involved. The Flexiterm MLCCs are offered in capacitance values spanning from 220pF to 100nF, with case sizes from 0805 to 2225 being available. They support an -55°C to +125°C operational temperature range. 5mm flexes can be comfortably handled (compared to the 2mm that MLCCs are normally rated for). Tests have shown them to have 0% failure after 3,000 thermal cycles (which is triple what conventional MLCCs can achieve).

Figure 2: Schematic showing the additional layer in one of the terminations of a Flexiterm MLCC [Courtesy of Kyocera AVX].

Conclusion

The automotive industry places exacting demands on the electronic hardware employed in vehicle designs, and the next generation of vehicle models (particularly those that are EV or hybrid) will only exacerbate this. High voltage levels will call for capacitors that have superior performance characteristics – and these components will need to withstand heavy vibrations, as they are now being placed into more difficult surroundings. The AEC-Q200 compliant MLCC solutions produced by both Kyocera AVX and KEMET, and available via TME, are addressing the situation. The game-changing product series that they have respectively developed leverage engineering advances that provide enhanced levels of ruggedness. This means that automotive engineers can be assured of long-term reliability even under the harshest of working conditions.