The convergence of advanced location technologies and smart manufacturing is transforming industrial operations at a fundamental level. The key enabler of this shift include nano GPS chips, which are ultra-compact, high precision tracking modules that are redefining how assets, materials, and workflows are monitored and optimized across the factory.

While GPS has long been a staple in fleet management and logistics, the miniaturization of GPS chips to nanoscale has unlocked new possibilities for real-time location systems (RTLS) in constrained, high-density, and fast-paced environments like smart factories. The growth trajectory of the nano GPS chip market is being driven by growing demand for tighter traceability, higher asset utilization, and integration with broader Industry 4.0 ecosystems.

Nano GPS Chips: What Sets Them Apart?

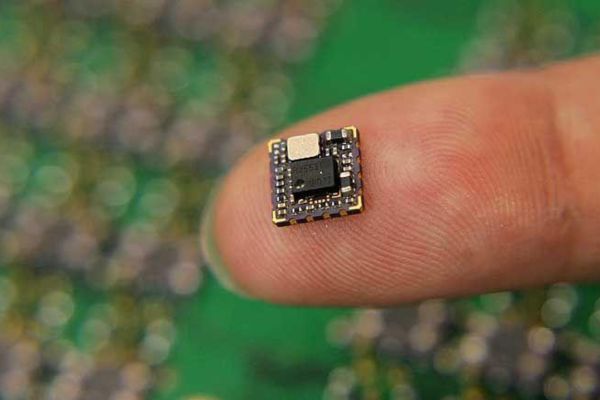

Nano GPS chips are typically smaller than a grain of rice, often less than 10mm² in footprint. These chips integrate antenna technology, low power GPS receivers, and signal processors into a single compact module. They are designed to offer precise geolocation, down to sub meter accuracy, with minimal power consumption. This makes them suitable for integration into wearable tags, mobile assets, handheld tools, drones, and embedded IoT devices.

Unlike traditional GPS units, nano GPS chips are engineered for environments where space, power, and bandwidth constraints are critical. They support multiple satellite constellations (GPS, GLONASS, Galileo, BeiDou) and increasingly integrate with local positioning systems, Wi-Fi, and UWB (ultra wideband) for indoor hybrid tracking, where satellite signals may degrade.

Market Growth: Key Drivers

1. Rising Demand for Asset Tracking and Inventory Management

In high throughput manufacturing environments, real-time asset visibility is non-negotiable. Nano GPS chips embedded in tools, containers, or automated guided vehicles (AGVs) provide precise location data to reduce idle time, eliminate bottlenecks, and enable just-in-time (JIT) material flow.

2. Workforce Safety and Compliance

In industries such as mining, oil and gas, and automotive, nano GPS chips are embedded in wearables or ID badges to monitor worker location and enforce geofencing rules. This not only ensures regulatory compliance but also enhances safety through automatic incident alerts and contact tracing.

3. Proliferation of Autonomous and Mobile Robotics

The rise of autonomous mobile robots (AMRs) and drones in smart factories is another key driver. These machines rely on nano GPS chips for navigation, path planning, and spatial awareness, particularly when operating in large or distributed plant layouts.

4. Integration with Digital Twin and Predictive Analytics

Nano GPS data feeds into digital twin models, providing spatial context to predictive analytics. Manufacturers can visualize machine-to-machine interactions, material movements, and energy flows in real time, enabling better planning and predictive maintenance strategies.

Innovation Trends in Nano GPS Chip Technology

As the market matures, innovation is pushing the boundaries of what is possible in positioning performance, power efficiency, and integration. Key areas of advancement include:

1. Ultralow Power Consumption

New chip architectures are achieving microwatt level standby modes and sub mill watt operation during active tracking. This enables multiyear battery life in tags, which is essential for largescale deployments in asset intensive environments.

2. Multimode Hybrid Positioning

Leading nano GPS chipsets now combine GNSS with inertial sensors, UWB, and Wi-Fi for seamless indoor-outdoor tracking. This hybrid approach ensures continuity of location data, even in GPS-denied zones such as warehouses or production basements.

3. Edge Computing Capabilities

Some nano GPS modules include on chip processing to perform location filtering, anomaly detection, and event triggering at the edge. This reduces network load and improves responsiveness in time-sensitive industrial processes.

4. Secure-by-Design Architectures

Given the increasing cybersecurity risks in connected manufacturing, nano GPS chips are designed with hardware encryption engines and secure boot features to ensure data integrity and prevent location spoofing.

Use Cases in Smart Manufacturing

1. Tool and Equipment Tracking

High-value tools equipped with nano GPS chips can be tracked in real time across production cells. This reduces tool loss, enables automated check-in/checkout processes, and provides usage analytics for preventive maintenance.

2. Vehicle and Forklift Navigation

AGVs and forklifts rely on nano GPS for dynamic routing and fleet coordination. Coupled with V2X (vehicle-to-everything) communication, this enables safer and more efficient material transport in large facilities.

3. Finished Goods and WIP (Work-in-Progress) Monitoring

By tagging WIP units or pallets with nano GPS-enabled devices, manufacturers can monitor production progress across stages, detect delays, and optimize space usage in staging or buffer zones.

4. Worker Location and Incident Response

Wearable GPS trackers allow managers to monitor worker distribution in real time and respond rapidly to emergencies or rule violations (e.g., entering restricted zones).

Conclusion

The nano GPS chip market is no longer just an emerging trend, it is a cornerstone of location-aware smart manufacturing. As innovation drives improvements in size, precision, and integration, these chips will play a crucial role across industrial ecosystems. For industry professionals planning digital transformation or IIoT deployments, nano GPS technology offers a strategic advantage to improve visibility, agility, and safety. The key lies in thoughtful implementation, aligning use cases, infrastructure, and security with business goals to unlock the full value of real-time location intelligence.

Source: nano GPS chip market