An era has emerged with new lighting technology evading the inevitable back white light. From mirrors to outdoor or indoor designs, a splurging and well-crafted luminescence is changing how we use lights redefining its existing applications.

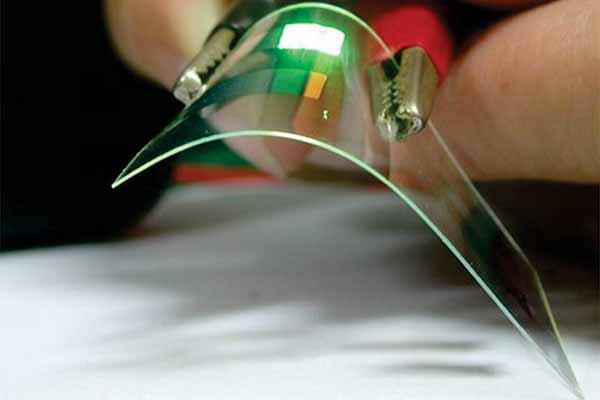

Thinner, lighter and more flexible is how today OLED (Organic Light Emitting Diodes) is defined. Often stated as a flat light emitting technology is in cognizant defining the future of electronics, yes electronics.

OLEDs are made by placing a series of organic thin films between two conductors with electrical current is applied, a bright light is emitted.

Display technology sector is already crony about OLEDs as these advance emitting diodes provide best image quality till now ever known. Also, OLEDs can be ‘shapeless’ – like it can be made transparent, flexible, foldable and even rollable and stretchable.

Some Interesting Applications Include:

- Curved OLED displays, placed on non-flat surfaces

- Wearable OLEDs

- Foldable OLEDs and rollable OLEDs which can be used to create new mobile devices

- Transparent OLEDs embedded in windows or car windshdields

So What’s Inside an OLED Display– Let’s Dive?

The key ingredient or the pivotal component in an OLED display is the OLED emitter – an organic (carbon-based) material emitting light when electricity is applied. Defining the structure includes an emissive layer integrated between a cathode (which injects electrons) and an anode (which removes electrons).

Substantially crafted with many more layers to enhance efficiency and making it durable, modern OLED devices OLED panel itself is made from a substrate, backplane (electronics – the driver), frontplane (the organic materials and electrodes as explained above) and an encapsulation layer.

OLEDs are very sensitive to oxygen and moisture and so the encapsulation layer is critical.

Currently most OLED displays are made using vacuum evaporation, using a Shadow Mask (FMM, Fine Metal Mask) to pattern – a relatively simple method but it is inefficient (a lot of material is wasted) and very difficult to scale up to large substrates.

Some OLED materials are soluble, and these can be deposited using printing methods – mostly ink-jet printing.

Inside a Simple OLED

Quite similar to conventional diodes and LEDs, OLEDs demonstrate same functionalities. The key difference from conventional LEDs is OLEDs doesn’t use layers of n-type and p-type semiconductors, they use organic molecules to produce their electrons and holes. A simple OLED is made up of six different layers. On the top and bottom there are layers of protective glass or plastic. The top layer is called the seal and the bottom layer the substrate. In between those layers, there’s a negative terminal (sometimes called the cathode) and a positive terminal (called the anode). Finally, in between the anode and cathode are two layers made from organic molecules called the emissive layer (where the light is produced, which is next to the cathode) and the conductive layer (next to the anode).

Why OLEDs Are Not The First-Choice?

Though OLEDs are defining the new-age off technology, seemingly it seems to have a brighter reality than its theoretical promises:

- Lifetime – While red and green OLED films have longer lifetimes (46,000 to 230,000 hours), blue organics currently have much shorter lifetimes (up to around 14,000 hours[source: OLED-Info.com]).

- Manufacturing – Manufacturing processes are expensive right now.

- Water – Water can easily damage OLEDs.

The Infancy OLED

Although the flexible OLED market is currently in its infancy, it is expected to grow in the future due to the rapid growth of the electronics industry. Electronic papers, clothing and wallpapers with flexible displays are a variety of applications for flexible OLEDs. Innovations in the display and electronics industries pave the way for better and more efficient flexible OLEDs. The rising demand for energy-efficient Flexible OLED in various end-use industries is expected to boost the growth of the Flexible OLED market in the future. Flexible OLED are used in major industries such as manufacturing sectors such as textile, plastics, automobile, steel, rolling mill, electric power, and port industries due to their high proficiency, ability, and ability to generate thrust. Many engineering and performance benefits, including a high degree of compatibility of parts and subassemblies, come from modular design and construction. As a result, significant cost savings can be achieved while maintaining the highest level of component integrity.

The COVID-19 outbreak has affected various industries worldwide. Governments around the world have implemented strict lockdown measures and social distancing rules to limit the rapid spread of the epidemic. In the early stages of the pandemic, manufacturing facilities around the world were shut down. Moreover, the post-pandemic economic crisis could cause significant delays in the commercial launch of the energy and power industries. Small businesses are the backbone of technology providers and have been witnessing sharp declines in sales since the advent of the 2020 pandemic. As such, market players face numerous challenges as supply chain disruptions have been observed. However, things will improve in the second half of 2022 as more supplies come online. It takes into account the impact of COVID-19 on the market demand, estimating the current and projected market size and growth trends of the market for all regions and countries.

Flexible Display – A Lighting Future Ahead

Due to their expanding use in flexible displays, wearable electronics, smart cards, and various other applications, flexible batteries are growing in popularity. A flexible display is also a rapidly growing technology, with applications of flexible display in areas such as media, aircraft, and transportation. Research on flexible display predicts increasing usage of this display technology in medical display systems.

The surge in demand for flexible display technology for a variety of applications such as digital signage, smartphones and tablets, and smart wearable devices is likely to drive the global flexible display market. The growing prominence of quantum dot (QD) display technology presents manufacturers with new revenue prospects and is likely to emerge as one of the important types of display technology.

The value of the global flexible display market stood at US$ 14.9 Bn in 2021. The market is likely to expand at a CAGR of 33.1% during the forecast period, from 2022 to 2031. The global flexible display market is predicted to surpass the valuation of US$ 242.6 Bn by 2031. Flexible displays include characteristics such as plastic-like thinness, lightweight, and durability, as well as the flexibility to be curved accurately and utilized in a variety of smart devices. Flexible display manufacturers & suppliers are also concentrating on modern electronics breakthroughs such as miniaturization, organic electronics, and improved materials. In order to diversify their income sources, they can take advantage of incremental opportunities in flexible display technologies.

OLED Emitter Material Market up 9% to $420 Million in Q1 2022

UBI Research says that the OLED emitter material market reached $421 million in Q1 2022, down 21.1% from the previous quarter, but up 9% compared to Q1 2021. UBI estimates that the OLED emitter material market will reach $1.77 billion in 2022, and will grow to $2.4 billion by 2026.

UBI says that sale of materials for TV and mobile devices decreased (compared to Q4 2021) while sales of materials for the production of IT (laptops, tablets and monitors) displays were up $6.6 million. The leading OLED material providers in the quarter were UDC ($86.6 million, with a 20% market share), DuPont ($41.3 million) and Duksan ($37.5 million). UDC actually saw increased material sales in the quarter (up from $85.5 in Q4 2021), as it has raised its prices.