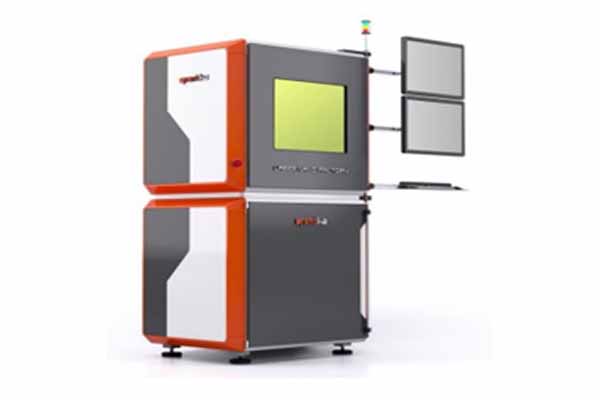

Basingstoke, U.K.- Founded in 2013, Femtika is a spinoff company of the Laser Research Centre of Vilnius University (Lithuania). The experts there have many years of experience in the research and development of 3D laser precision micromachining, and they specialise primarily in hybrid micromachining technologies. For example, Femtika produces universal tools with femtosecond lasers suitable for multiphoton polymerisation, laser ablation and selective laser etching technologies. The heart of a laser nanofactory workstation always consists of a femtosecond laser in combination with a nanopositioning system from Aerotech. Overall, this enables fast and highly precise 3D manufacturing across the entire workspace.

Femtika has been using Aerotech’s linear stages and galvo scanners since the company was founded in 2013. However, the first contacts occurred much earlier, as the University of Vilnius has been using Aerotech equipment since 2005. There, Femtika’s founders used Aerotech equipment intensively for research projects and other academic work.

Dr. Vytautas Purlys, CTO at Femtika, looks back fondly at the company’s early days: “Before we were introduced to the Aerotech positioning stages, we assumed that nanometre precision could only be achieved with piezo stages.” The most common solution at the time was to mount the piezo stage on a larger, less precise mechanical stage. “This approach was sufficient for small structures, but for larger structures we always had problems with stitching and extremely long manufacturing times,” continues Purlys. “We then tried Aerotech’s high- precision linear stages, which immediately improved the quality for larger microstructures and also allowed them to be manufactured faster – by at least a factor of 10.” Soon after, it became clear that the speed could be increased by a further factor of 10 if they incorporated Aerotech’s AGV galvo scanner. “I remember one project where we produced thousands of high-quality structures overnight, while our older piezo system only managed ten in the same time,” he enthuses.

3-D Printing With Multi-Photon Polymerisation

One of Femtika’s most commonly used processes is multiphoton polymerisation, one of the highest resolution 3D printing technologies. This process is based on photopolymerisation reactions that are triggered only in a focal volume of the sharply focused femtosecond laser focal point. The microstructures are printed by scanning the laser beam over the volume of the photopolymer.

“A key advantage of this process is the ability to print very high resolution of structure sizes down to 150 nm,” explains Purlys. “In addition, there is an exceptionally high surface quality and the ability to create 3D micro objects of any shape without the need for supports.”

Examples of applications for multiphoton polymerisation are micro-optical and photonic elements, which are not only printed on planar surfaces but also directly on fibre tips, photodiodes, semiconductor ICs, etc. The process is also frequently used for biomedical applications such as the production of 3D scaffolds, which are support structures for cell growth that can be used for drug testing.

One Machine for a Variety of High-Precision Processes

Femtika’s laser nanofactory machines are not just very high resolution 3D printers. They also offer many other microfabrication techniques made possible by femtosecond lasers. This means that the same machine can perform a variety of processes that would not be possible in the traditional 3D printing world.

“Our workstations are often used for selective laser etching of glass, for example,” says Purlys, citing a common practice. “Unlike 3D printing, this is a subtractive process where the laser is used to modify the intermolecular glass structure. The laser-modified glass areas are then chemically etched away, leaving only unmodified areas.” This is not only applied in medical technology (in microfluidic devices or micromechanical particles, for example) but also in microrobotics and the watch industry.

“In general, lasers are unique tools because of their ability to modify the volume of transparent materials without touching their surface,” continues Purlys. By modifying the volume of materials, different waveguides, diffractive optical elements or Bragg gratings can be realised. Surfaces can also be modified with femtosecond lasers. For example, microablation is used when tiny grooves or holes are needed on the surfaces, while surface structuring enables the production of hydrophilic or hydrophobic surfaces.

Building Small Features Over a Large Area

Each laser process places its own unique demands on the positioning system. Some processes require precision and resolution, others speed, still others a working range, and all this together results in quite a demanding list of requirements. “Since all of our processes are based on

functional material changes, the specifications of the positioning system directly contribute to the quality of the manufactured structures,” emphasises Purlys.

Stitching together small areas to create a larger part is one of the most essential aspects in the world of submicrometer printing. This is not only caused by inaccuracies of the positioning system, but also by the material’s behaviour. The Femtika CTO illustrates the problem with a pictorial example: “Imagine you are on the beach. While you are lying comfortably in the sand, you try to draw a circle with your finger. Between the place where you started the circle and the place where you finished it, you will notice a defect – a small pile of sand. No matter how steady and precise your hand is, the pile will be there. Now try to draw a larger pattern with small, ‘gridded’ squares – imitating the effect of the galvo scanner. You will find that your artwork is full of such heaps or ‘stitches’ between the squares.”

Similar problems occur in the micro world, caused by the way the materials react to the laser pulses. Often the galvo scanners are used to raster the laser spot over small square areas, which are then joined by repositioning them in steps, leading to errors in the joining process. This approach can significantly affect the quality of the manufactured structures. For example, microlenses manufactured in this way show considerable scattering, micro parts can contain fractures, and parts for the watch industry lose their aesthetic appeal.

“To minimise the number of stitching errors, we actively use infinite-field-of-view technology, where the movement is automatically divided into a fast and a slow movement and executed simultaneously with Aerotech’s galvo scanners and linear tables respectively,” explains Purlys. “In this way, the stitching is eliminated and the structures produced become more uniform.”

Control Is the Key

The system’s overall precision is thereby limited by the least precise component, so the performance of the stages and galvos must be precisely matched. However, this is not the only important factor. The control system is an often overlooked component that performs a very important, almost invisible task.

With direct laser writing techniques, the structures are written while the table/galvo scanner is moving. When the positioning system is accelerating or decelerating, the number of laser pulses hitting the material increases. This can lead to various errors or even material damage in these areas. These problems can be solved by firing the laser pulses at constant distances from each other. If both galvo scanners and mechanical tables are used, this poses a challenge for the control system as the positions of both devices have to be taken into account.

“As longtime users of Aerotech’s A3200 controller, we were excited to be able to test the new Automation1 control platform as well,” explains Purlys, before offering his verdict: “Apart from the significant improvements to the user interface, we also discovered many new useful

features. For example, the way the movement is defined is now much more user-friendly, the control parameters are easier to find and their meaning is now also easier to understand. From the integrator’s point of view, we like the new control API, which makes the implementation of various control functions much easier.”

During the software migration, Femtika’s experts noticed some functions that previously required 50 lines now can be implemented in just a few lines of code. “Many other small improvements helped us save implementation time and increased the overall quality of our products,” concludes Purlys.