Modern robotics is the driving force behind the aerospace industry’s ongoing evolution. The field of robotics has developed significantly over the past few years. Much of the progress focusing on commercial applications uses for the manufacturing of aerospace. Aerospace engineers predict that robotics might eventually be pivotal in the development of the aerospace and transportation sectors.

How Have Recent Developments in Aerospace Robotics Revolutionized Our Reach into the Sky?

These five developments offer a glimpse of the fascinating direction the industry is propelling towards

1. Welding

Automation has been a major trend driving the aerospace business over the past few years. Almost every sector is noticing this viral trend however aerospace is where it really shines. For instance, automated welding expedites production while increasing the safety of new aircraft.

Even for experienced workers, welding poses risks. Burns, radiation, electric shock, and fumes are just a few of the dangers that welders may encounter. It could result in serious injuries. One of the most typical objectives of automation is to reduce the risk that people are subjected to.

Robotic welding is becoming increasingly prevalent, particularly for highly precise materials such as titanium and nickel alloy. Robots can perform welding efficiently while also bolstering productivity as they can repeat the same process endlessly without compromising quality. This expedites production, strengthens the structural integrity of new airplanes, and boosts worker security at assembly sites.

2. Drilling and Fastening

The drilling and fastening process has arguably been the aerospace industry’s most widely used application of robotics. For assembly line workers, this is a tedious. Prolonged task that needs specialized tools and several steps to be correctly implemented. All of that can be automated, greatly accelerating the manufacturing process. Even with specialized materials such as titanium, robotics is capable of handling the entire process, from drilling the pilot hole to reaming.

Automating this procedure is a ground-breaking development in the industry given the enormous number of holes. It must be drilled in airplane parts. As a result of the advantageous position, it has given many aerospace businesses, automated drilling and fastening are now the norm in the sector.

Fastening is to the aircraft business what welding is to the automotive sector, according to Dan Friz from KUKA Systems in an interview from 2016.

3. Sealing, Painting, and Coating

Eliminating repetitive, time-consuming processes is the secret to success when it comes to productivity. The use of robotics in sealing, painting, and coating procedures is becoming increasingly common in the aerospace industry. Productivity is more crucial than ever since there is a growing need for new aircraft. This is due to a shortage of private jets in the market. A much-needed solution is being offered by robotics for automated manufacturing.

The sealing, painting, and coating processes take too long for human workers to complete, despite being essential for quality and safety. The size of the aerospace robot parts they are working with is mainly responsible for this. People can focus on more important tasks due to robotics. As parts progress down the assembly line, a sealing and coating robot can be programmed to repeatedly apply the same seals with consistent quality. These time-consuming procedures can even be completed by robots overnight or during off-peak times when nobody is in the mood to work.

4. Transportation

Large aircraft components are transported from one location of an assembly facility to another. This process is one area in which robotics is improving safety in the aerospace sector. Human workers may be at risk during this process, and hence this challenge calls for careful attention to prevent damage to other machinery or components. Since stress has been shown to increase the likelihood of human error, and rigging specialists may face high levels of stress while doing their job.

It makes sense that many airline firms are integrating automated transportation systems into their assembly lines. These hauling and rigging robots can now move airplane parts securely and autonomously while utilizing specialized sensors to scan the ground for people. This is a testament to how far robotics has come.

5. Inspection

Over the past few years, sensor technology has advanced to a great extent. The capabilities of current technology are increasingly outpacing those of the human senses, from smartphone cameras that can recognize faces with precision to infrared sensors that can track heart rate.

By using sensors to increase the accuracy of their non-destructive testing, many aerospace businesses are utilizing this technology. Robotics, however, has the potential to significantly increase both the speed and precision of inspections. By meticulously and methodically checking every square inch of components for cracks and other flaws, they can ensure quality and integrity.

Moreover, sensors can be used to check for structural properties such as the quality of the countersink and the exit burr. Robotic systems that perform inspection scans automatically can be set to operate during off-peak hours, much like the sealing, painting, and coating processes. In this approach, human workers can make the most of their daily schedules for handling any problems the inspection robots detect.

All of the aforementioned trends in the aerospace robotics business are expected to contribute significantly to growing the sector at a rapid pace. Extrapolate’s study estimated that by 2028, the global aerospace robotics sector may generate up to USD 4.9 billion in revenue.

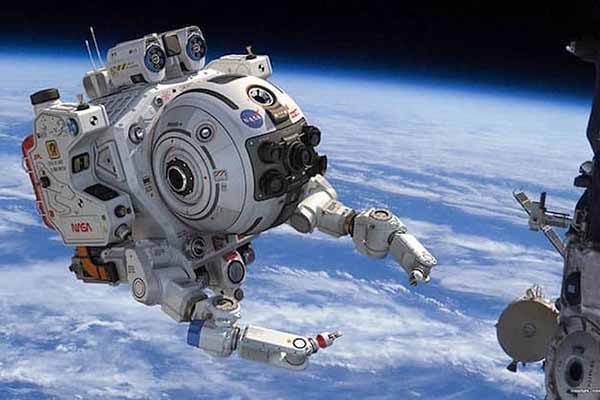

Are Robots the Future Astronauts?

The field of aircraft robots has a bright future and enormous growth potential. Unmanned aerial vehicles (UAVs) have been identified as a crucial part of tomorrow’s aircraft by engineers and physicists who are conceptualizing the future of transportation. Also, UAVs won’t merely be utilized for military purposes. More public transit options are desperately needed since the global transportation sector is experiencing rising strain. Leaders in the industry believe that UAVs might be the perfect solution.

In its “Vision 2050” project, the Aerospace Industries Association highlighted the potential of widespread UAV use. According to the AIA’s forecast for 2050, everyone may eventually use completely autonomous flying “pods” to go around, similar to airborne taxis. These cutting-edge robotic planes would ease traffic on the roads and railroads and perhaps even cut carbon emissions.

Imagine that UAVs for public transportation were widely available, reasonably priced, and powered by renewable energy. In that situation, many people might swap them for traditional vehicles or buses in the future. They would be flown using AI, much like driverless cars do now.

Meanwhile, completely autonomous assembly lines are likely to start appearing in the industrial sector of the industry soon. The above-mentioned developments hint at this development, which would aid in addressing the current lack of private aircraft as well as the rising demand for aircraft as outlined by the AIA.

Boldly Going Beyond Human Limits

The aerospace field will witness many innovative new developments in the future, with robotics playing a particularly fascinating role. Robots are already transforming the sector and establishing new benchmarks for safety, productivity, and quality assurance. Whether in the cockpit or working behind the scenes on the assembly line, they are anticipated to power the aircraft of the future.

About the author:

Alisha Patil is a budding writer and a bibliophile by nature, Alisha has been honing her skills in market research and B2B domain for a while now. She writes on topics that deal with innovation, technology, or even the latest insights into the market. She is passionate about what she pens down and strives for perfection.