Today, globally, we human beings are the creators of so-called “intellectual factories”. It means “all real-time technologies” that make our lives easier. During this period, some are still trying to get rid of paper, others are catching up, and several are moving towards innovation, and the real end of this is a human endeavour. In addition, major improvements in software and systems, processes, and methods, as well as in optimization, automation, value creation, and transformation of user experience, will ultimately be fully realized in our future, depending on people. At every step of the day, we are surrounded by Internet connections, from our houses to cars, and we are all connected to society. Moreover, because of the existence of the Industry 4.0 Markets, we are today part of the fourth industrial revolution. Considerable progress has been made from the identification of pathways to the identification of today’s corporate risk factors and losses. Today, products and production tools are networked, with the ability to “communize” and open the door to innovative production technologies, value creation, and real-time optimization. That is also why today’s task has become much easier for all industrialists.

What’s industry 4.0?

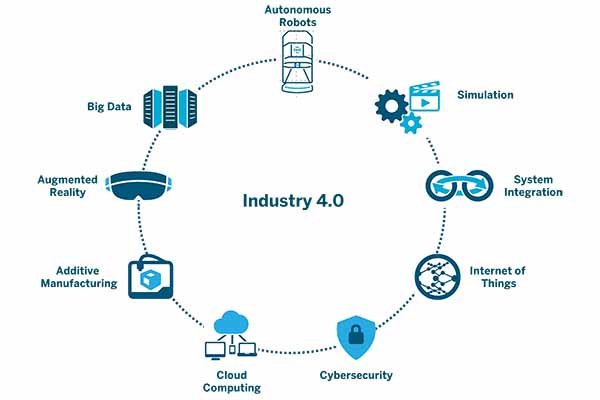

The term “industry 4.0” refers to the information-intensive transformation of manufacturing and related industries in the interconnected environment of big data, people, processes, services, systems and Internet-enabled industrial assets to generate, use and utilize actionable data and information to achieve intelligent industries and industrial innovation and collaboration ecosystems. Industry 4.0 is therefore a broad vision with different frameworks and reference designs, whose main feature is the integration of digital technology and physical industrial assets into so-called network physics systems. Industry 4.0 is based on network physics systems, such as “smart machines.”. To connect and resolve through the object network, they use contemporary control systems, have embedded software and have Internet addresses. Products and production tools thus become networks with the ability to “communise” and open the door to innovative production technologies, value creation and real-time optimization.

The three technological areas of innovation are:

- Numeric pairing

Digital pairing is a core component of a real smart factory. In essence, twins are cloud-like representatives of a product or asset. This technology can be used for very precise simulations. Digital twins are easy assets for various pilots, such as the performance of key elements of the pressure test system or the validation of certain engineering assumptions, with real-time data collected from sensors, predictive analysis algorithms and ML algorithms, without a commitment to expensive physical prototypes

- Forecast maintenance

Unplanned equipment failure times and sudden breakdowns are good friends who do not want to tilt the manufacturing industry. A new generation of forecast maintenance solutions, driven by state-of-the-art machine learning algorithms, can identify early signs of failure and even predict pre- failure

Industrially industrial iodide (pestrochemical)

- Industrial information Internet (material networking)

Industrial IT deployments are growing at a very rapid pace, for a good reason: connectivity makes the manufacturing process clearer. The most recent sensor arrays capture data points ranging from temperature to sound and vibration, all of which generate a great deal of knowledge about the equipment’s operating conditions or the condition of the goods produced/carried.

Why is industry 4.0 called the “fourth industrial revolution”?

Industry 4.0 is referred to as the “fourth industrial revolution” because we have moved from “only” Internet and customer server models to “unomnipresent flows”, “connection of digital and physical environments (known in manufacturing as “network physics systems”), information technology and digital technology and the combination of all the technologies mentioned above (material networking, big data, clouds, etc.) with advanced robotics and other accelerators such as Artificial Intelligence and Cognitive technologies, which have enabled the industry to automate and optimize 4.0.

According to Forbes, Rolls Royce is one of the first companies to deploy a full-service provider to consolidate its position as the main engine supplier. Its philosophy is based entirely on industrial 4.0 digital technology. Together with the ” Full Care ” service package, the company rents engines from airlines and pays monthly fees to cover all maintenance work. Their profit margins are maximized. Rolls collects sensor data from engines and estimates optimal maintenance schedules using predictive algorithms. In this way, they provide added value to clients without straining their operating costs.

The legacy of innovation is growing

This sector has undergone a digital transformation, with industry at 4.0 at the top. It provides real-time decision-making, increased production, flexibility, and flexibility. The reasons for these industries today range from developing better production and streamlining processes to increasing consumer demand for customized goods and experiences. The widespread disruption of fast virtual markets is also a reason for the expectations of such cutting-edge innovation. In the coming years, this will lead to growth for Industry 4.0 Markets with more and more dependence of the population on it.