OLED (Organic Light Emitting Diodes) is a flat light emitting technology, made by placing a series of organic thin films between two conductors. When electrical current is applied, a bright light is emitted. OLEDs are emissive displays that do not require a backlight and so are thinner and more efficient than LCD displays (which do require a white backlight). OLED displays use less power, provide better picture quality and wider viewing angles than their competitors. However, the real coolness of OLED is its potential. Whilst current interactive OLEDs mimic the movie Minority Report, with their ability to swipe and manipulate on-screen translucent images, expect bigger things to come soon, with foldable, rollable and wearable OLED products all in the pipeline.

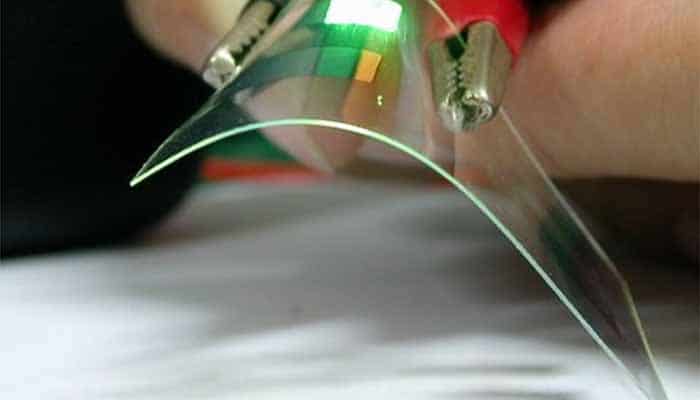

OLEDs can be used to create flexible and transparent displays. This is pretty exciting as it opens up a whole world of possibilities:

- Curved OLED displays, placed on non-flat surfaces

- Wearable OLEDs

- Foldable OLEDs and rollable OLEDs which can be used to create new mobile devices

- Transparent OLEDs embedded in windows or car windshdields

- And many more we cannot even imagine today…

What makes up an OLED?

An OLED consists of 6 layers that all play a role in making the OLED well-structured and energy efficient:

- Seal: Glass top plate

- Cathode: Negatively charged electrode (attracts cations)

- Emissive Layer: Made up of organic molecules or polymers that transport electrons from the cathode layer

- Conductive Layer: Made up of organic molecules or polymers that transport holes from anode layer

- Anode: Positively charged electrode (attracts electrons or anions)

- Substrate: Glass bottom plate

How do OLEDs Emit Light?

Electrical current needs to be applied to the anode and cathode layer for the OLED to emit light. Energy travels from the cathode layer, through the organic material (emissive and conductive layer), and to the anode layer. The current gives electrons to the emissive layer and removes electrons from the conductive layer. The removal of the electrons leaves holes in the conductive layer that need to be re-filled with electrons. To recombine with electrons the holes jump from the conductive layer to the electron-filled emissive layer. As the electrons fill these holes extra energy is released, which produces the bright, electroluminescent light that is visible through the outermost layer of glass (substrate and seal).

Instead of having a backlight, like in LEDs, the OLED’s display is self-illuminating because of its organic material. Since there is no backlight, the OLEDs are significantly thinner than standard LCD or VFD modules.

Pros and Cons of an OLED

Pros

- Generates all colors/Bright images

- Wide viewing angle (nearly 90°)

- Low power consumption (when viewing darker colors)

- Fast response time

Cons

- Some OLEDs are moisture sensitive

- Limited life (mainly due to sensitivity to moisture)

- Higher power consumption (when viewing brighter colors)

- Prolonged exposure to UV light can damage OLED

Flexible OLED Market

The Flexible OLED market was valued at USD 3.12 billion in 2019 and is expected to reach USD 63.35 billion by 2025, at a CAGR of 39.46% over the forecast period 2020 – 2025. OLED display technology, which provides beautiful and efficient lighting panels, is already being used in many mobile devices and TVs. Flexible OLED is the next-generation technology that enables the opportunities for folding and curving these displays on applications.

- The smartphone market is one of the fastest-growing markets in the world. Also, it needs rapid technological advancements in the offerings for achieving a competitive edge over other players. As smartphone penetration is reaching new highs every year, the demand for OLED display for this segment is driving the flexible OLED market.

- The low consumption of energy has also driven the market for LED displays, and the flexible OLED displays opened new opportunities of application in the industry. The innovative applications in the automotive and lighting industry will moreover fuel market growth.

- The economies of countries across the world are growing. Hence, the population is now equipped with higher disposable cost than before, insisting consumers for adopting luxury products like curved OLED Televisions.

- On the other side, the lower acceptance of the OLED technology compare to the LED displays is restricting the market growth.

Is QLED the same as OLED?

Though they don really similar acronyms, an OLED TV is not the same as a QLED TV. The latter is actually based on LED tech, but it uses a technique that overlays self-emissive quantum dots over the pixels that help produce better brightness, vividness, and color accuracy. QLED is more of an iterative step than a generational leap, and though we’d certainly recommend buying one if OLED is out of reach, expect its eventual deprecation as technologies like quantum dot OLED (QD-OLED) and microLED take hold.

Technical Insight

The OLED contains three basic layers: the cathode, anode and organic layer. In early OLEDs, the organic layer consisted of an emissive layer and a conductive layer. When a current is passed through the material, electrons are generated at the cathode, and “holes” are generated at the anode. The electrons and holes travel into the emissive layer and conductive layer, respectively, and combine at the interface of the two layers. This combination moves an electron from the lowest unoccupied molecular orbital (LUMO, analogous to the conduction band in LEDs) of the emissive layer to the highest unoccupied molecular orbital (HOMO, analogous to the valence band in LEDs) of the conduction layer. This transfer results in the release of energy in the form of light. However, more modern OLEDs employ an organic layer containing a hole transport layer (HTL), an electron transport layer (ETL), and an emissive layer. In this setup, the HTL and ETL transport electrons and holes to the emissive layer. Once localized on the emissive layer, the holes and electrons eventually combine and release light. Using three organic layers instead of two has been shown to increase OLED efficiency. OLEDs are currently divided up into two classes: small molecule OLEDs (SMOLEDs), which use small organic molecules in their organic layer and polymer OLEDs (POLEDs), which use organic polymers. SMOLEDs as a class can be further broken down into two sub-classes based on if the light is generated using fluorescence or phosphorescence.