Introduction

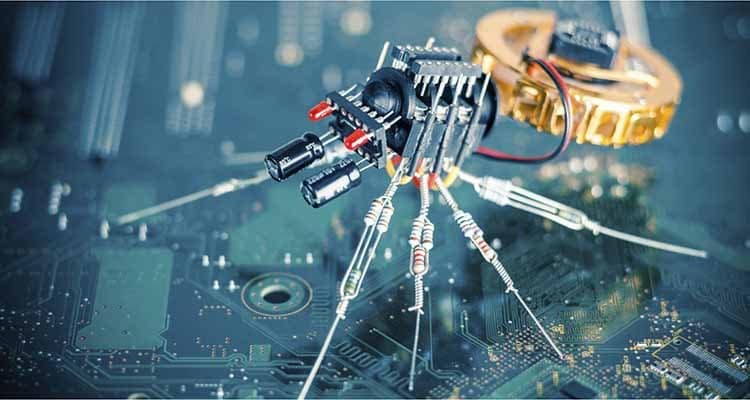

Micro-electro-mechanical systems (MEMS) is the present future. Micro-electro-mechanical systems (MEMS) have become so pivotal because of its qualifying quality of having technology of both electronic and mechanical components. MEMS consist of various components, such as sensors, actuators, miniaturized structures, and microelectronics. In countries like Japan & Europe, MEMS are also known as micromachines & microsystems technology (MST). Why MEMS are witnessing the market heat is the reason because of the growing adoption of smart connected devices and Internet of Things (IoT) market marking dollar possibilities for future. There are variable example for MEMS and its applications seems to just growing and is expected to sweep every other application we cross through in coming future. In MEMS, a wide variety of transduction mechanisms can be used to convert real-world signals from one form of energy to another, thereby enabling many different microsensors, microactuators and microsystems. Despite only partial standardization and a maturing MEMS CAD technology foundation, complex and sophisticated MEMS are being produced.

History While We Open up MEMS

Though, the very first commercial applications for MEMS technology were seen as pressure sensors which were used by the automobile and medical industries. But today, MEMS as mentioned earlier are superlative to many other applications spread over numerous market sectors. From its development time, i.e. 1970s and early 1980s was early time called as micromachining. Interestingly, the name MEMS became more affluent in the early 90s when U.S. Department of Defense started eyeing into its potential and divulged investments. The first commercial application of MEMS technology was microsensors used to detect strain in steel, and these devices were used primarily in the automobile and medical markets. According to Dr. Michael Huff, the founder and director of the MEMS and Nanotechnology Exchange (MNX), which offers MEMS design and fabrication services, the first generation of these sensors was developed following a discovery by an employee of Bell Telephone.

The MEMS IC fabrication can be done with silicon, whereby slight material layers are placed otherwise fixed onto a Si substrate. After that selectively fixed away to leave microscopic 3D structures like diaphragms, beams, levers, springs, and gears. The MEMS fabrication needs many techniques which are used to construct other semiconductor circuits like oxidation process, diffusion process, ion implantation process, low-pressure chemical vapor deposition process, sputtering, etc. Additionally, these sensors use a particular process like micromachining.

Types of MEMS

The common types of MEMS sensors are obtainable within the market are

- MEMS accelerometers

- MEMS gyroscopes

- MEMS pressure sensors

- MEMS magnetic field sensors

MEMS Advantages

The advantages of MEMS sensor include the following.

- The manufacturing of MEMS is semiconductor IC manufacturing like low-cost mass invention, consistency is also essential to MEMS devices.

- The size of sensor sub-components will be within 1 to 100 micrometers range as well as the MEMS device size will determine 20 micro-meter to a millimeter range.

- Power consumption is very low.

- Simple to incorporate into systems or change

- The thermal constant is small

- These can be highly opposed to shock, radiation, and vibration.

- Better thermal development tolerance

- Parallelism

Applications

Smart homes, smart wearable devices, and huge growth in the automotive industry are some of the drivers that are impacting the growth of this market. Though the potential of MEMS doesn’t just resist to this as wide variety of novel MEMS product are well-suited for space exploration and it is said that in near future MEMS applications can beyond Mars. Consumer electronics such as smartphones, tablets, laptops, digital cameras, portable media players, and navigation devices are also wooing the MEMS market. In airborne, automotive, industrial, defense, mining, surveying, naval & marine — manned & unmanned in each sector — these silicon MEMS accelerometers are redrawing market lines and opening up new possibilities for high-performance navigation and guidance.

IoT & MEMS

Electronics and automotive industries have been by far two of the most attractive markets for MEMS. The automobile industry in recent years has made substantial strides driven by the demand for safer automotive. This has propelled the demand for various safety features based on MEMS, such as air bags and tire pressure monitoring systems, thus boosting the MEMS market. Further, growing incorporation of advanced sensor based on MEMS in wearables and the growing popularity of such wearables are factors boosting the global MEMS market. The demand for high-performance fitness trackers is a case in point. The global MEMS market has also been receiving substantial leg up from its rising relevance in sensors used in internet of things (IoT).

The IoT has an enormous requirement for tiny, low-cost sensors to monitor all aspects of production; these sensors must communicate the information to other nodes in the factory network and must operate reliably in the harsh electrical and mechanical environment of the factory. MEMS devices are tailor-made for this purpose: they’re small, rugged, and lend themselves to the inclusion of additional circuit blocks in the same package for wired or wireless connectivity.

Industrial robots use MEMS-based 3-D gyroscopes and accelerometers to continuously measure changes in angular rate and direction, replacing expensive rotary sensors and encoders. They can also detect excessive vibration in joints and actuators that might be omens of premature failure.

MEMS accelerometers also detect unwanted vibration in other industrial machines or sense unwanted shocks. Pressure sensors measure water flow and gas pressure; gas sensors check for toxic emissions; and temperature sensors are a key part of many processes.

In the IoT network infrastructure, MEMS oscillators find a welcome in the programmable logic controllers (PLCs) that supervise the operations of robots and other units. And optical devices are suitable for use in human-machine interface (HMI) display screens.

Future Diving into MEMS Technology

Microelectronics companies are recently leveraging the transformative potential of MEMS in industrial applications and in niche applications in systems used for wearables and electronic appliances. Underpinning their pursuits are advances in sensor technologies used in MEMS. Autonomous vehicles need dozens of sensors to interact with their surroundings. These sensors also have to be as small as possible so they don’t take up space needed for other equipment, carrying people and batteries. The automotive industry is consequently one of the fields in which MEMS sensor production and use are expected to grow most. As we have seen in the previous example, a package of a thousand can be used for lots of cars and thus cut the cost of implementing an immediate alert system following rollover (for example with an automatic blind call to the emergency services) to just a few cents for the sensors. A further field in which using MEMS technology is being explored is microphones. A MEMS microphone makes it possible, for instance, to reduce the size of hands-free devices for mobile phones and to build much smaller and more discreet aids specifically for people with hearing problems. The most spectacular and at the same time extensive and interesting usage scenario is perhaps biotechnology and medical technology.