Electronic display systems have always attracted the inventor’s attention to fulfil/achieve the desired outcomes of displays like color quality, display quality as a function of viewing angle, height, distance etc. and many options are being put forward with time. Plasma display panels (PDP) also called as Gas-Discharge Display emerged once as strong contenders to different electron displays. It consists of an array of small lights. Plasma screens offer several advantages. They have excellent color accuracy and can display deep blacks, which results in high contrast and vibrant images. They also provide wide viewing angles, meaning you can see the screen clearly from different positions in a room. An electric field excites the atoms in a gas, which then becomes ionized as a plasma. The atoms emit photons at ultraviolet wavelengths, and these photons collide with a phosphor coating, causing the phosphor to emit visible light.

A plasma display panel (PDP) is a type of flat panel display often used for large television displays (typically above 37 inches or 940 millimetres (mm)). Many tiny cells located between two panels of glass hold an inert mixture of noble gases (neon and xenon). A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large (over 32 inches diagonal) flat panel displays to be released to the public. Until about 2007, plasma displays were commonly used in large televisions. By 2013, they had lost nearly all market share due to competition from low-cost LCDs. Presently, plasma displays are obsolete, having been superseded in most if not all aspects by OLED displays. Presently, however, liquid crystal displays (LCDs) meeting almost all display requirements with low cost have already gained a niche over all other electronic display panels. LCD (Liquid Crystal Display) is a type of flat panel display which uses liquid crystals in its primary form of operation. LEDs have a large and varying set of use cases for consumers and businesses, as they can be commonly found in smartphones, televisions, computer monitors and instrument panels.

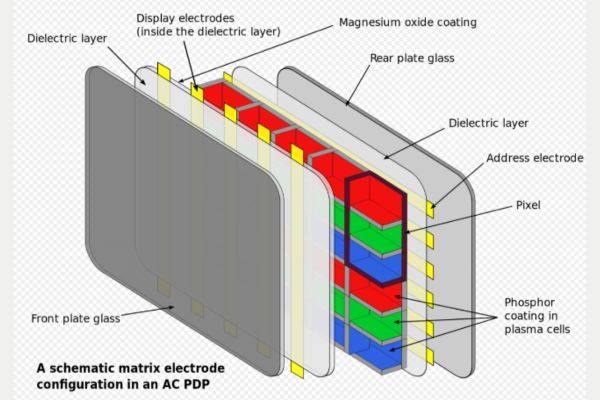

The alternating current plasma display panel (AC-PDP), a typical dielectric barrier discharge (DBD) technology, offers several good features, including a big screen, a thin and light flat panel, a broad viewing angle, rapid response, high resolution, and complete digitization, etc [96,97]. In the current consumer electronics industry, it is one of the most favored wall-hanging flat panel TVs and high-definition TVs. The recurrent effect of wall-charge buildup on the surface of the dielectric layer in discharge cells underlies the functioning of AC-PDP. The memory effect produces an AC-PDP voltage functioning tolerance by efficiently reducing the maintained voltage. It is essential to reducing the consumption of energy and achieving stable AC-PDP functioning. Wall-charge build-up has up till now been considered a beneficial aspect of AC-PDP functioning. Picture sticking is the result of an itinerant strong sustain discharge that lasts for many minutes throughout a sustain period. When a previous picture is constantly presented for a few minutes, a ghost image persists in the succeeding image. The phosphor layer’s degradation was the primary cause of the ghost image’s reduced brightness; the brilliant image’s luminance is mostly generated by the high discharge that happens during the sustain period (Testing in MgO surface or phosphor layer for 42-in plasma display panel) [100]. The discharge qualities of the dielectric layer are significantly influenced by its surface characteristics, including its shape and orientation. Various surface conditions can yield distinct gas DBD characteristics.

PDPs have a decreased discharge gap width of 80–100 pm and a breadth of around 200 pm for each cell. In order to minimize intercellular communication, ribs that are usually 50 pm thick and 100 pm high are placed between adjacent cells. These cells may be created using somewhat cheap production procedures such as thick film printing or by sandblasting or engraving onto a flat glass plate. At filling pressures between 10 and 100 kPa, a combination of helium and xenon or neon and xenon serve as the filling gas. Every single cell may be addressed with two sets of thin electrode strips arranged perpendicularly. The electrodes of ac PDPs are covered with magnesium oxide thin protective coatings and dielectrics. The main source of the electron beam is the photoelectron emission from the cathode, which is caused by radiation from the working-gas atoms excited by fast heavy particles in a highly non-uniform electric field in the cathode cavity. MgO’s low sputtering rate ensures long life times, and its high coefficient of secondary electron emission is used to lower the operating voltage. Ions and rapid atoms are likewise dispersed by such a field, which lowers their fluxes towards the cathode. The observed results suggest that open-discharge microstructures with a cathode cavity can serve as a foundation for the creation of extremely efficient light sources and plasma panels. These microstructures make it possible to convert electric energy into light very effectively. 200 V integrated driver circuits can power PDPs. For an AC-PDP model, the dielectric barrier discharge in mixes of Ne–Xe or Ne–Xe–Ar was established. In order to analyze the mechanism of VUV radiation and discharge efficiency as well as the luminous efficiency, these models were used to evaluate electron temperature, plasma density, excited atom density, wall charge density, discharge current density, excimer density, and VUV intensity, as well as their gas composition-pressure dependencies.