What is the automotive BMS?

People familiar with cars will certainly also be familiar with ESP (Electronic Stability Program), ABS (Antilock Brake System), TCS (Traction Control System), and other on-board systems, which together constitute a protective net for automobile security. For example, safety systems such as ABS has been required by law for all new cars throughout most countries.

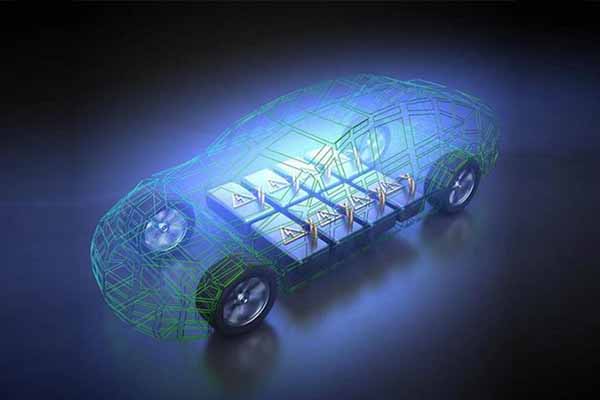

There is also a very significant system on electric vehicle, which is BMS (Battery Management System). BMS is no less important to electric vehicle than the above systems. It can monitor the battery status in real time, manage the on-board power battery, enhance the battery efficiency, prevent the battery from over-charging and over-discharging, and improve the service life of the battery. Nowadays, electric vehicles are developing so rapidly. How to stand out from many EV cars? A high-quality battery management system (BMS) is necessary for a high-performance electric vehicle.

All these electronic systems in a car are equipped with battery voltage regulators and battery chargers, which can manage power supplies for input and output of 5V, 12V, 24V and 48V. It is well known that electric vehicles will consume a large amount of electricity, so the supporting accessories and electronic systems grow every year. The size, weight, and quantity of supporting power components, as well as the BMS system, need to match the growth of electricity demand.

The requirements of power supplies in BMS

The BMS system’s power module is powered by a battery or an EV charger. There are many BMS modules in a car, and each module is powered by a battery. In order to ensure that the power provided by each BMS module will have no interference with each other and keep the independence of a single module, it is necessary to use an isolated DC/DC power supply between the BMS and battery. The input voltage range of this isolated DC/DC power supply should be wide enough to ensure the regular operation of the BMS system

Therefore, the requirements of the BMS system for the power module are briefly summarized as follows:

- Wide input voltage range to suit with battery

- Wide working temperature range

- High reliability requirements for long-term usage

- Compact size, strong compatibility

Therefore, Mornsun has launched the automotive grade power modules, such as CUWB12XXYMD-6WR3 series, which has excellent performance and is suitable for most complex and harsh industrial field applications. It is an ideal solution for DC power supply of BMS systems.

It features:

- Ultra wide input voltage range of 4.5 ~ 36VDC

- Ultra wide operating temperature range of -40℃ to +105 ℃/-55 ℃ to +125 ℃.

- Production process meets IATF16949 system requirement

- Excellent EMC platform and supporting services

- Excellent EMI: simple peripheral can meet high-level EMI and corresponding EMS.

The one-stop power supply solution from MORNSUN

As shown in the figure above, CUWB1205YMD-6WR3 is used as the main power supply of the unit, which meets the management and control of IATF16949 system. The CF0505XT-1WR3 product mainly isolates the CAN interface and ADC detection. As the core of the BMS, the blue block processes the data of each slave module and then exchanges data with other systems. Electric vehicles have broadened the industrial boundaries, driving the economy more and more actively, and industrial integration innovation has further contributed to high-quality economic development. The power supply of automotive electronic on-board systems has strict industry specifications. The one-stop power supply solution from Mornsun is used to solve the pain points of the electric vehicles power supply market. Mornsun’s automotive-grade power supply provides the most effective guarantee for the reliable operation of automotive electronic systems.

For more information, please visit www.mornsun-power.com