Equipment used to manufacture semiconductor devices, including memory chips and integrated circuits, is referred to as semiconductor manufacturing equipment. The semiconductor sector has advanced significantly over time, becoming crucial for powering the devices we rely on daily. Semiconductor chips are the foundation for modern innovation, fuelling everything from smartphones and laptops to cutting-edge medical technology and vehicle electronics.

The complicated circuitry that serves as the basis for semiconductors is built using these sophisticated, precision-driven devices. Semiconductor manufacturing equipment enables the fabrication of high-performance chips that power our linked world via technological advances and stringent engineering.

Unveiling Semiconductor Manufacturing Equipment

This equipment is generally used in highly specialized semiconductor fabrication facilities, also referred to as “fabs” or “foundries,” which work in pristine environments to avoid contaminating the fragile electronic components they are producing.

Electronic circuits are gradually built on a wafer made of pure single-crystal semiconducting material, often silicon, using a range of manufacturing techniques, including deposition, removal, patterning, and electrical property modification. Since yield is a crucial aspect in guaranteeing that a high percentage of microchips function correctly, the sector is highly automated, and production frequently takes several weeks.

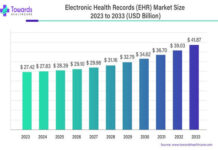

Extrapolate states the global semiconductor manufacturing equipment is anticipated to reach USD 175.0 billion by 2028, with a robust CAGR of 8.5% during the forecast period. These figures show unequivocally that the market is anticipated to have rapid expansion in the near term. The industry’s innovations and trends are expected to drive continued, lightning-fast advancements in semiconductor production equipment, which will revolutionize a variety of industries along the road.

Why is the World Fostering Semiconductor Manufacturing Equipment?

Semiconductor manufacturing equipment is finding application in numerous sectors, from electric vehicles to technological advancements like the Internet of Things (IoT).

Electric, networked, and autonomous cars employ semiconductors extensively. This is driving the market for equipment used in semiconductor production ahead. For instance, although hybrid electric vehicles can include up to USD 1,000 and USD 3,500 worth of electronics, traditional automobiles typically carry USD 330 worth of semiconductors. The growing usage of semiconductors in autonomous and hybrid vehicles is therefore expected to drive growth in the market for semiconductor manufacturing equipment.

Additionally, according to CRS Reports, the typical number of semiconductor chips in a car is around 3,000, however hybrid electric vehicles may have more than that.

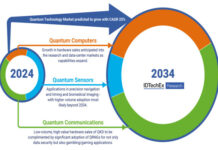

Furthermore, the accelerating development of Artificial Intelligence paved the way for the growth of semiconductors. One of the main factors in maintaining the market is deep learning chips, a subset of entire artificial intelligence systems.

According to the United States International Trade Commission, the artificial intelligence semiconductor market, for instance, was estimated to be worth over USD 17 billion in 2017 and is expected to grow to USD 65 billion by 2025. The effect of such a growing tendency in the semiconductor business is supplementing the growth further.

Multi-dollar Gigantic Companies Are Betting on Semiconductor Manufacturing Equipment Like Wildfire

The largest and most cutting-edge equipment collaborative process manufacturing research and development (R&D) center for semiconductor technology will be built by Applied Materials as part of a historic investment.

Applied Materials is one of the global leaders in the semiconductor industry. The American company provides tools, services, and software for producing flat-panel computers, smartphones, television displays, and solar devices.

The advanced facility, new Equipment, and Process Innovation and Commercialization (EPIC) Center are to be located in Silicon Valley. This innovative step is anticipated to propel the industry further.

There are other titans contributing to the growth of the semiconductor manufacturing equipment market, one such is TEL (Tokyo Electron Ltd).

The Japanese firm TEL, which dominated the semiconductor market from the 1980s through the 1990s, experienced a severe decline in business in the 2000s as new competitors and technological advancements changed the landscape of the sector. Despite a dramatic decline in fab capacity and chip manufacture, Japan still provides 30% of the equipment needed to make semiconductors and 40% of the world’s semiconductor materials.

It is impossible to overestimate TEL’s role as a leading manufacturer of manufacturing equipment in the advancement of semiconductor processing. Toshiki Kawai, president and chief executive officer of TEL, asserts that “no cutting-edge semiconductor chip can be made without TEL’s technology.”

With multiple companies stepping forward the semiconductor manufacturing equipment industry is anticipated to boom at a robust growth rate.

Is Semiconductor Manufacturing Equipment Getting Choked Due to US and China Clash?

After Japan declared on May 23 that it will put export restrictions on 23 types of chip making technology, including advanced semiconductor manufacturing equipment, China’s semiconductor industry is now under renewed pressure from the United States and its allies.

In an effort to restrict China’s access to sophisticated semiconductor chips and equipment, the US and the Netherlands enacted similar regulations in recent months.

The US government implemented a number of export restrictions on cutting-edge semiconductor devices in October. Since then, Washington has pushed the Netherlands and Japan to support its efforts to impede China’s semiconductor industry’s growth.

China has reacted fiercely to US export restrictions on cutting-edge, high-performance semiconductor technologies and processors. They have criticized the limitations and set aside money for financial incentives and subsidies to support China’s chipmakers in acquiring and developing semiconductor technology so they can become self-sufficient. In general, China has indicated a goal to increase its domestic semiconductor sector and minimize its reliance on imported semiconductors.

Winding It Up

The production of semiconductor devices requires a variety of specialized tools and apparatus, which are vital to the semiconductor manufacturing sector. Companies like Applied Materials have grown to be significant suppliers of the machinery required for semiconductor production as the industry has developed. Additionally, numerous countries are coming up with establishing facilities to augment the overall growth of the market.

For instance, China has indicated a goal to establish its own domestic semiconductor sector, which involves investing in creating and purchasing semiconductor technologies, in order to lessen its reliance on foreign semiconductors. Given how crucial semiconductor manufacturing equipment is to the sector, businesses and governments should put a lot of effort into it.