The global 3D printing medical devices market was valued at US$ 1.7 billion in 2022. Projections indicate a robust growth trajectory, with an estimated compound annual growth rate (CAGR) of 16.3% from 2023 to 2031. By the end of 2031, the market is expected to reach US$ 6.6 billion.

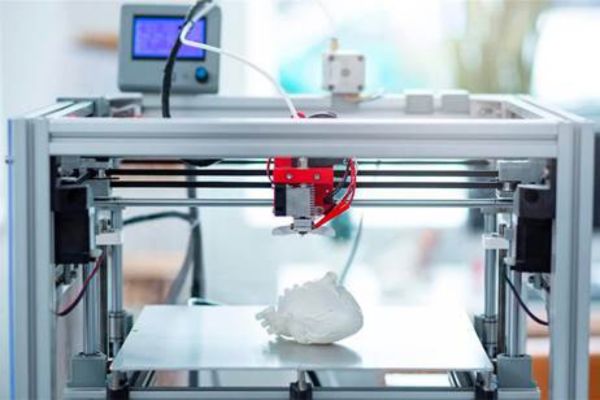

The 3D printing industry has witnessed remarkable growth, with applications expanding across various sectors. Among these, the 3d printing medical devices market has emerged as one of the most promising and impactful areas, revolutionizing the healthcare landscape. This market segment encompasses a wide range of products, from prosthetics and implants to surgical instruments and anatomical models, all produced through additive manufacturing techniques. In this article, we explore the evolution, current state, and future prospects of the 3D printing medical devices market.

Evolution of 3D Printing in Healthcare:

The adoption of 3D printing in healthcare represents a paradigm shift, offering personalized solutions, rapid prototyping, and cost-effective production. The journey began with the development of patient-specific anatomical models, allowing surgeons to plan and practice complex procedures with greater precision. As technology advanced, 3D printing expanded to encompass the production of customized implants and prosthetics tailored to individual patient anatomy.

Current Landscape:

Today, the 3D printing medical devices market is characterized by a diverse array of products and applications. Customized implants, such as hip and knee replacements, spinal cages, and dental implants, have gained traction due to their ability to enhance patient outcomes and reduce the risk of complications. Prosthetic limbs, traditionally manufactured using standardized designs, are now being produced with 3D printing techniques, offering improved comfort and functionality for users.

Moreover, the use of 3D printing in surgical planning and training has become commonplace, enabling surgeons to visualize complex anatomical structures and simulate procedures before entering the operating room. This has led to shorter surgical times, reduced risk of errors, and improved patient safety.

Challenges and Opportunities:

Despite its significant potential, the 3D printing medical devices market faces several challenges. Regulatory requirements, particularly concerning the approval and certification of 3D-printed devices, remain a major hurdle for manufacturers. Ensuring the quality, consistency, and biocompatibility of printed products is essential to ensure patient safety and regulatory compliance.

Furthermore, the scalability of 3D printing technologies for mass production needs to be addressed to meet the growing demand for customized medical devices. While additive manufacturing offers flexibility and customization advantages, achieving cost-effective large-scale production without compromising quality remains a challenge.

Future Outlook:

Looking ahead, the future of the 3D printing medical devices market appears promising, driven by advancements in materials science, technology, and regulatory frameworks. Materials with enhanced biocompatibility, durability, and sterilization capabilities are being developed to expand the range of applications for 3D-printed medical devices.

Moreover, the integration of artificial intelligence (AI) and machine learning algorithms is poised to optimize the design and manufacturing processes, enabling rapid iteration and customization of medical devices. AI-driven algorithms can analyze patient data, such as medical imaging scans, to generate personalized designs that address individual anatomical variations and optimize implant fit and functionality.

In addition, collaborations between industry stakeholders, including healthcare providers, regulatory agencies, and technology developers, are crucial for driving innovation and standardizing practices within the 3D printing medical devices market.