Evolution of Electric Aviation

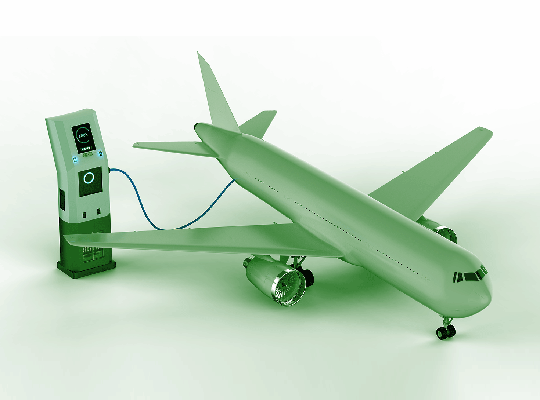

Two French army officers tried to use electricity to propel an airship in the 1800s, but ran into complications when the battery couldn’t contain enough energy. For the following 100 years, this would be a recurring issue. Aircraft can be powered by hybrid-electric drive systems. They’re quiet, and the separation of energy and thrust generation allows for entirely new aircraft designs. Electrification of aeroplanes promises more efficient, silent and sustainable flight while also lowering fuel consumption and operating costs for airlines. Current limits on carbon emissions and noise pollution, as well as the high cost of fuel and concerns about efficiency, make developing a substitute power source for aeroplanes a priority. Simultaneously, advances in power and energy density have taken electric solutions to the point where they are now technically and economically viable to existing aircraft propulsion systems. Electric flight, the next revolution in electricity, will enable us to meet our carbon reduction goals while also providing travellers with a new class of quieter, more ecologically friendly transportation well into the next century. With one billion additional people on the earth and six billion yearly fliers predicted by the International Air Transport Association in the coming decades, the rationale for promoting electric aviation is apparent. To reduce pollution in the atmosphere, electric motors are being used to power aeroplane propeller engines. Because gasoline motors need to be repaired 10 times more frequently than electric motors, electric aviation also implies fewer hours of regular maintenance. However, because batteries are bulky, the first electric planes are likely to be modest commuter planes. Aviation Aircraft had a backorder for more than 150 of its nine-passenger Alice planes with a 650-mile range in prior years.

Revolution Journey of Aviation

From automobile to marine, electric and hybrid-electric propulsion is fast revolutionising mobility systems. The aviation sector is no different. Our work in electric flight at Airbus seeks to pave the way for industry-wide adoption and regulatory acceptance of alternative-propulsion commercial aircraft and urban air vehicles in the future. Airbus began its electrification adventure a decade ago, building CriCri, the world’s first all-electric, four-engine aerobatic aircraft. Since then, substantial progress has been achieved in the electrification of flying. In 2015, the E-Fan, an all-electric twin-propeller aircraft, successfully crossed the English Channel. Vahana and CityAirbus, our electric vertical take-off and landing (eVTOL) demonstrator projects, have completed numerous hours of rigorous and thorough flight testing to assure safety and excellent performance. The E-Fan X, a 30-times more powerful successor to the E-Fan, has provided crucial insights into serial hybrid-electric propulsion. Air travel contributed approximately 2.5 percent of global carbon emissions in 2019, with that figure expected to treble by 2050. While some airlines have begun to offset their carbon emissions, significant reductions are still required. Many businesses are racing to create electric aeroplanes, which could provide the amount of disruption required. Electric propulsion motors would not only eliminate direct carbon emissions, but they would also lower fuel expenses by up to 90%, maintenance by up to 50%, and noise by nearly 70%. Airbus, Ampaire, MagniX, and Eviation are among the businesses working on electric flying.

Electric Aviation and Market Investment

All are undergoing flight testing in order to obtain certification from the US Federal Aviation Administration for aircraft intended for individual, corporate, or commuter journeys. Cape Air, one of the major regional airlines, hopes to be one of the first clients, with plans to purchase Aviation’s Alice nine-passenger electric plane. Cape Air’s CEO, Dan Wolf, has expressed interest in not only the environmental benefits, but also the possible financial reductions. Electric motors have a longer life expectancy than the hydrocarbon-fuelled engines of his present aircraft, requiring an overhaul every 20,000 hours instead of every 2,000. Wings on conventional jets must be large enough to create lift at low speeds, but the enormous surface area increases drag at higher speeds. Electric propellers provide more lift during takeoff, allowing aircraft lower wings and greater efficiency overall. Electric planes will have a limit on how far they can travel in the future. The finest batteries now produce significantly less power per kilogramme than traditional fuels: 250 watt-hours per kilogramme compared to 12,000 watt-hours per kilogramme for jet fuel. As a result, the batteries necessary for a particular flight are significantly heavier and take up far more space than ordinary gasoline. By 2025, approximately half of all flights will be less than 800 kilometres, which will be within the range of battery-powered electric aircraft. Electric aircraft confronts economic and regulatory challenges, but investors, incubators, businesses, and governments are enthusiastic about the technology’s growth and are spending heavily in its development: between 2017 and 2019, $250 million was invested in electric aviation start-ups. Approximately 170 electric aeroplane designs are now in the works. The majority of electric planes are built for private, corporate, and commuter travel, but Airbus claims that 100-passenger versions will be ready to fly in the next decade. The inability to completely eliminate emissions in any combustion alternative, despite the knowledge that emissions-free fuels can be developed. To begin with, with the industry focused mostly on radical new designs and alternatives that may never achieve zero-emissions or ensure efficient use of zero-emissions resources, aviation appears to be falling behind in the energy transition. Other industries, on the other hand, can achieve complete zero-emission performance in a relatively short period of time utilising already available technologies. Second, while the small-scale 250-500 km travel segment may not be as lucrative as large-scale long-haul flights, it does represent a sizable market.

Future possibilities in the market

An experimental technological implementation for electric propulsion might be made with a tested aeroplane between 2021 and 2023. This could be any airworthy pressurised turboprop single plane whose engine is nearing a major overhaul. Ground tests of the motor and ancillary systems would guarantee that significant progress toward certification could be made. In 2024-2025, new battery technology insights could be used to choose the newest and best battery technology, replacing the temporary battery with a definitive, certified option. Finally, the entire plane might be set up for low-effort battery swaps. This would enable the launch of a rolling battery technology certification procedure, which would allow for incremental endurance improvements over time. Speedboats and aeroplanes are actually quite similar. They both require a lot of electricity and are light, thus their electric propulsion performance and endurance are restricted by the number of hefty batteries they can carry on board. It became obvious after studying existing certified airframes and electric motors, as well as planned and foreseeable iterations on present battery technology, that fully-electric 250+km flights with up to 6 passengers will be feasible between 2025 and 2027. Furthermore, due to the inherent inefficiency of energy use in alternatives such as sustainable aviation fuels and hydrogen, these flights would be considerably ahead of any other important breakthroughs in sustainable aviation.