The aerospace robotics market is growing at an unprecedented pace as the aviation industry continues to evolve. The use of robotics has become a critical part of the aerospace industry, with advanced robots and autonomous systems transforming the way we design, build, and maintain aircraft.

One of the most significant trends in the aerospace robotics market is the increasing adoption of collaborative robots or cobots. Robots are designed to work alongside humans it provides greater flexibility and efficiency in aerospace manufacturing processes. With their ability to perform repetitive tasks with accuracy, cobots have become an essential tool for aerospace manufacturers, helping to reduce production time and improve quality.

At the same time, the growing demand for autonomous drones. The use of drones in the aerospace industry has increased significantly over the past few years, with the development of advanced technology enabling drones to perform a range of tasks, including surveillance, inspection, and cargo delivery. As the demand for drone technology continues to grow, manufacturers are investing heavily in research and development to create more sophisticated drones capable of performing complex tasks with greater efficiency.

According to Allied Market Research, the global aerospace robotics market is projected to showcase a significant CAGR from 2020 to 2030. The market is driven by the growing demand for unmanned aerial vehicles (UAVs) and increasing automation in aircraft manufacturing.

A number of companies are investing heavily in the development of innovative products and technologies for the aerospace robotics market. One such company is Airbus, which has been developing a range of autonomous technologies for its aircraft. These include the Airspace Connected Experience, which integrates multiple systems on board an aircraft to improve passenger comfort and safety, and the Skywise platform, which uses data analytics and artificial intelligence to optimize aircraft performance.

Another company that is making significant strides in the aerospace robotics market is Boeing. The company has been developing a range of autonomous technologies for its commercial aircraft, including the Autonomous Systems for Remote Operations (ASRO) program, which is aimed at improving the safety and efficiency of aircraft operations.

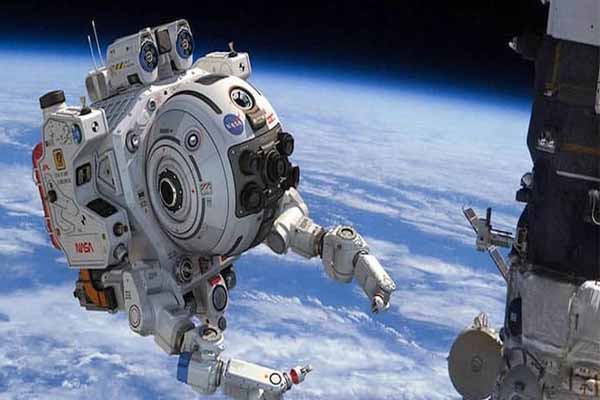

The use of space robots for various applications is being pursued by private companies in collaboration with NASA. One notable development is the Sample Acquisition, Morphology Filtering and Probing of Lunar Regolith (SAMPLR) robotic arm, which was awarded a USD 5 million contract from NASA in February 2020. SAMPLR will be used to explore the moon by collecting samples to determine its geotechnical properties. To accommodate the increasing use of space robots, NASA is working on developing modules for their storage in space.

In December 2019, the Robotic Tool Stowage (RiTS) was attached to the outside of the International Space Station to provide protective storage for critical robotic tools. NASA plans to enhance human and robotic collaborations for its space exploration projects, including the Moon, Mars, and deep space missions. Increasing investments in space robotics and the growing development of new space robots have paved the way for lucrative opportunities in the industry. For instance, the Indian Space Research Organisation (ISRO) unveiled the Vyommitra half-humanoid robot in January 2020, which will be onboard the “Gaganyaan” crewed orbital spacecraft set for launch later in 2020.

The space robots market has become increasingly competitive in the past few years, with the entry of several startups and the involvement of government space organizations. For example, JAXA has partnered with GITAI to develop humanoid telepresence robots for space missions. Investment firms are also showing interest in this promising industry, as seen in the acquisition of MDA by Northern Private Capital for CAD USD 1 billion. As a result, companies in the space robots industry are enhancing their capabilities to secure new contracts and expand their market share.

Airbus has recently granted Tata Advanced Systems Ltd (TASL) with a contract to produce cargo doors and bulk cargo doors for the A320neo aircraft family. This decision is aimed at enhancing Airbus’ standing in the single-aisle aircraft market and providing support for the A320 programme’s ramp-up.

The onus of manufacturing these doors using cutting-edge robotics and automation technology has been bestowed upon TASL, at their state-of-the-art facility in Hyderabad. TASL has been given the pivotal role of creating these doors, which will consist of two cargo doors and one bulk cargo door, using advanced automation and robotics techniques.

To conclude, the aerospace robotics market is poised for significant growth in the coming years, driven by the increasing demand for unmanned aerial vehicles and the adoption of advanced robotics and autonomous systems in aircraft manufacturing. With the development of innovative products and technologies, aerospace manufacturers are well positioned to take advantage of this growing market and continue to push the boundaries of what is possible in the world of aviation.