With ~90% of industrial heating processes using fossil fuels, this has led to approximately 25% of global energy pollution coming from heat produced for industrial processes. As such, demand for technologies to decarbonize industrial heating is expected to increase. One such technology that is able to store and supply heat to industrial processes is thermal energy storage (TES). TES for industrial applications currently only forms a minor percentage of global TES capacity, given that TES systems have been widely deployed in applications such as pairing with concentrated solar power (CSP) plants, district heating, cold chain, and space heating for buildings. While there have been reports of reductions in global CO2 emissions from industry in recent years, the magnitude of these annual reductions will need to increase if countries are to meet their wider net-zero targets. Therefore, the proportion of global TES capacity represented by systems used for providing decarbonized industrial heat is expected to ramp up over the next decade. From IDTechEx’s new market report “Thermal Energy Storage 2024-2034: Technologies, Players, Markets, and Forecasts”, the industrial TES market will be valued at US$4.5B by 2034.

Key drivers for industrial thermal energy storage

While TES systems offer reduced emissions for heat production compared to fossil fuels, recently, higher and volatile natural gas prices in key regions have highlighted an additional benefit TES offers, which is potentially reduced and more stable costs for heat production. Also, governments and states are providing funding to players developing technologies to decarbonize industries, such as through the EU Innovation Project and the US Department of Energy’s Heat Shot. However, it is not always clear how much funding is being funneled to TES players specifically, as players developing other industrial decarbonization technologies are competing for this funding. Depending on the initiative, TES players are likely to receive portions of funding to help commercialize their technologies and expand manufacturing capacities. These factors related to emission reductions, cost benefits, and provision of government-led funding are expected drivers to promote industrial TES market growth in key regions.

Working principles of thermal energy storage

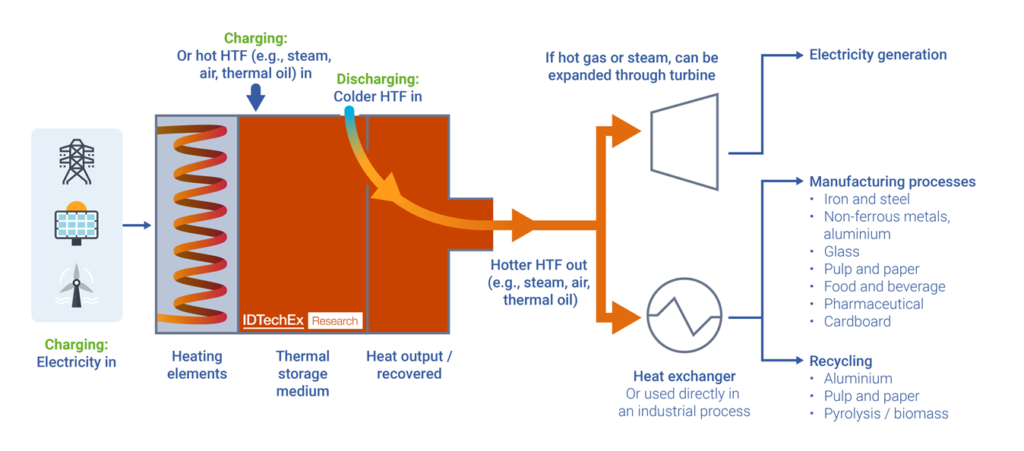

Thermal energy storage technologies can be classified into different types of system. This could include sensible heat, latent heat, thermochemical energy storage (TCES), and electro-thermal / pumped thermal energy storage (ETES / PTES) technologies. Sensible heat systems see materials such as molten salt, concrete, refractory brick, and crushed rock being commercialized and deployed in industry. Latent heat systems are also being developed, for example using silicon as the thermal storage medium. Such technologies could see heat transfer fluids (HTF) being heated on discharge as they pass through the TES system and then passed through heat exchangers or applied directly to an industrial heating process. Some TES technologies can accept renewable electricity as an energy input, using resistive electrical heating elements to heat up the storage medium. Other technologies may accept excess heat capture, e.g., in the form of steam, as an energy input, and some technologies can accept both forms of energy input.

TCES technologies are in an earlier stage of development, and further optimization of materials, as well as greater awareness and funding of these technologies, is needed to bring them to market. ETES systems focus more on generating power, using a turbine-generator on discharge to convert heat to electricity to achieve this. Several key players are developing these systems for long-duration energy storage (LDES) applications. TES technologies can generally adopt turbine-generators as part of wider system design, but this would come with associated conversion losses from heat to electricity, which would result in a lower round-trip efficiency (RTE) of ~50-60% to provide electricity compared to incumbent Li-ion stationary energy storage technologies which can achieve RTEs of ~95%.

Given the variety of designs, TES technologies are versatile and, depending on the materials used and types of energy input and output, can be used in a range of industrial applications. IDTechEx’s market report appraises the various thermal energy storage technologies being developed and commercialized and analyzes their suitability for a range of applications. This includes suitability for industrial heating processes against requirements for temperature and type of heat (e.g., convective, conductive, radiative, steam, air), such as calcination, drying, process fluid heating, metal and glass melting, as well as power generation, LDES, and more.

Future market outlook

As of January 2024, TES players have accumulated over US$600M in funding to develop their technologies and scale business operations and manufacturing capacities. A few key GWh-scale TES projects are due to come online over the next few years in the US and China (which are not for concentrated solar power applications). As suggested in IDTechEx’s market report, while these large-scale systems skew short-term TES regional outlook, most projects being planned to decarbonize industrial heating processes are due for deployment in Europe. Recent spikes in European industrial end-user natural gas prices and their seldom return to pre-2021 prices have created opportunities for TES systems to be more cost-competitive than in other regions. However, players in the US and Australia continue to scale their TES manufacturing capacities, add to their project pipelines, and develop novel materials to withstand higher storage temperatures without compromising materials’ mechanical or thermal stability. These developments will see a greater capacity and variety of commercialized TES systems being deployed across industrial sectors to decarbonize heating processes over the next decade.