Change is the only constant, may it be a human or machine, everyone, and everything goes through a change. As the race of humanity grows, machines are also simultaneously evolving.

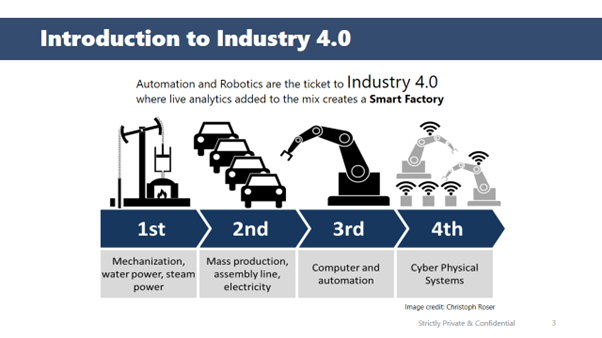

The industrial revolution has grown from being driven by water and steam power to today’s age where smart machines connected to Wi-Fi work without any hassles.

If you see the above picture you will notice the evolution of the Industrial revolution. As we move from Industry 1.0 to Industry 4.0, notice the computer and robotics in Industry 3.0 which ushered the sea of change of how people look at machines now. In Industry 3.0, most of the time, robots were working in isolation, and even if they were connected that is for limited and that to a certain segment only.

However, in Industry 4.0, robots got connected to the cloud and communication with other devices like smartphones or other smart devices as possible. A lot of other development also happened during this period. Natural navigation got developed due to which machines/robots started walking. Vision technology got integrated with machines/robots with which robots were able to see. Due to advancements in conversational AI robots started to talk and chat. And these are the features that have made the machines and robots smart, which in turn means that they now need limited instructions on what they should be doing.

Apart from this, in Industry 4.0 a major shift we saw that predictive maintenance by machines. Machines were able to predict their breakdowns and were able to communicate with customers through the cloud. E.g. Like a person enter the lift and hears hear a voice that lifts my breakdown. It is up to the person who wants to go on board or not. Meanwhile, the lift will share the message with the lift’s technician. Then the technician would come and does it work and send the bill to the owner. The customer pays it via the cloud. So the whole chain is communicated and closed through the cloud and the machines only got smarter through the ages.

Robots are nothing but machines, and they lack natural intelligence but works on the intelligence that is fed to them. The robot works on various sensors and vision-based cameras. These items along with algorithm forms machine AI (artificial intelligence). Artificial intelligence allows the machine to take decisions.

However, with artificial intelligence, the last mile automation is either not feasible or is very costly. There are many tasks which a robot could do, but we have to teach them first and that was expensive. Generally, these are done by humans and call for reasoning which was not monotonous. Hence, there’s a harmonious development that’s occurring, which includes the participation of both humans as well as robots.

The robots which work with humans are known as CoBots, e.g. if a robot puts a thread in the needle that would cost. That is why putting needles can be done by humans and stitching by robots.

However, robots especially the technically advanced ones, are used to perform bigger tasks, which a human would take a longer time to complete. Industry 4.0 will be majorly dependent on these AI-driven robots to deliver faster and efficiently and usher in the most successful phase in the industrial revolution history.

To give humans the best chance of doing a good job, we need to provide them (us) with the most relevant information for the task at hand. Humans are good at solving the problem. When a factory needs to change its output tomorrow due to a change in demand for its products today, we can feed the demand data into our software, but it’s the human that will need to evaluate if this is a sensible thing to do. Create logistic and warehousing policies separate from industrial promotion policies: State governments are mandated to form separate policies for the development of the logistic and warehousing industry so that the industries can grow their full potential

If Industry 4.0 is about the interaction of the physical world with the automated, data-driven world, then we should spend more time designing the role of the human and when designing the systems, they will be using, invest time and effort to ensure that a truly intelligent enterprise creates the environment for a human to succeed.