Overview

Smartwatch manufacturers frequently need to design a wireless charger for their new lines of products. Figure 1 reveals how USB Type-C charging protocol was selected by the manufacturer’s designers for the wireless charger, to address their main concern regarding safety and reliability. The design needed a 5V, 1A charger, but the USB Type-C charger power distribution standard enables a maximum output of 100 W. Moreover, with a maximum voltage and current of 20 V and 5A. Therefore, a USB Type-C charger should have a 100 W capacity to meet the standard.

The designers specified the safety requirements for their chargers as follows:

- Up to 20 V overvoltage protection

- Up to 5 A overcurrent protection

- Maximum surface temperature of the component under 80° C

Maximum charging wire temperature under 50° C.

They were challenged to conform to these requirements within the constraints of the size of the wireless charger.

Finding the right solution was key

The engineers designing this solution had specific safety requirements for overvoltage detection, overcurrent detection, and temperature sensing. One potential solution includes a fuse, Zener diode, temperature sensors, and control ICs combination. It represents too many components for the limited available PC board (PCB) space. It makes sense for us to use an electronic fuse IC as an alternative because it combines all these components in one space-saving package.

Although several competitive electronic fuses have an adequate input voltage of 20 V, their output voltage is only 12 V. This cannot survive a 20 V @ 5 A test. As such, it was a struggle to meet the project’s safety requirements with the available competitive components.

Solution:

Littelfuse proposed the design team utilized the LS0505EVD22 Series eFuse, a 5 V, 5 A integrated protection IC with overvoltage and overcurrent protection. While providing all the necessary protection, this electronic fuse (eFuse) IC conforms to the requirements of the USB Type-C power delivery standard. The IC can safely withstand 100 W of power. And is not damaged if the Type-C power delivery adapter supplies 20 V and 5 A. As shown in Figure 2, there is a block diagram of the LS0505EVD22 eFuse whose output is controlled by a series MOSFET with a low 50 mΩ RDS(ON). The low RDS(ON) reduces the IC’s power loss and temperature rise. Test data indicates that the temperature of the IC will only rise by 37° C when operating at 5V @ 1 A, and an input short appears for 20 minutes.

The parallel MOSFET provides overvoltage protection, a current limit block issues programmable overcurrent protection. Additionally, a thermal protection block supplies overtemperature protection. Controlling the rise time of the output to prevent a potentially hazardous overshoot condition, soft start is another function of the IC. The input and output voltage rating of the eFuse is 30V. It is higher than that of the available competitive products. This ensures the reliability of the eFuse because 30 V considerably exceeds the maximum USB Type-C rating of 20 V. Moreover, the IC packaging is a space-saving DFN2X2_8L Package. In Figure 3, eFuse protects a portable device in a USB Type-C power circuit.

Design win for eFuse

While the LS0505EVD22 Series eFuse earned the Littelfuse team a significant design win, the satisfaction of being chosen by the customer design team should not be overlooked. Being thoroughly tested by the design team, eFuse passed all their performance and stress tests by meeting or exceeded all their requirements. In addition, eFuse offered flexibility to allow designs available with 5 V and 3 A output in the future, saving the design team development time and cost as there was no need to select and qualify a new component.

While the performance of eFuse was the first significant contribution, another substantial contribution to the design win was the support of the Littelfuse application engineers. They provided responsive on-site technical service and consultation. The combination of a quality Littelfuse product and superior technical support was the base for a great design win.

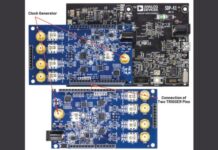

For details on Littelfuse eFuses and evaluation boards, see the Protection IC